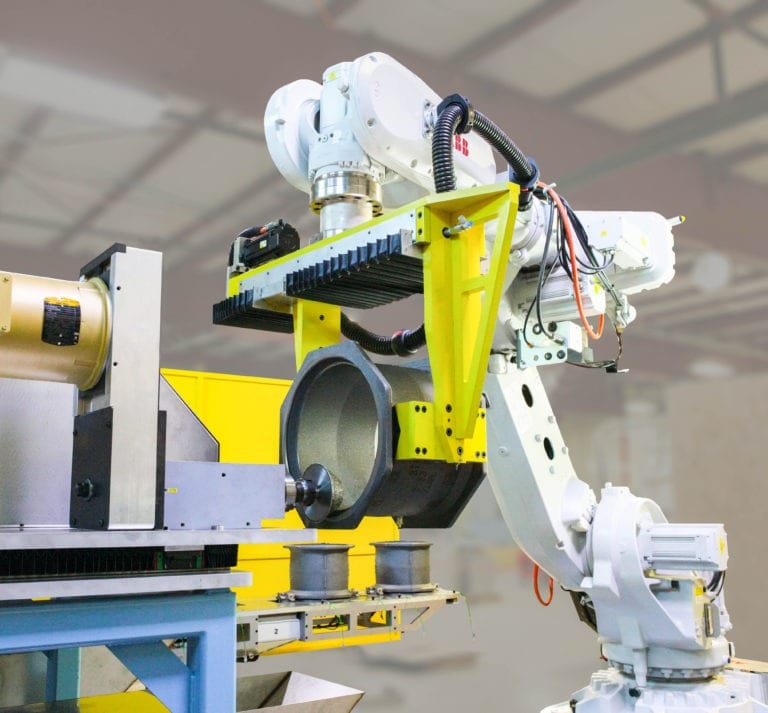

MACPal OF

The MACPal “OF”– is designed for robotic palletizing of mixed cases.

MESH’s heritage is, at its core, custom solutions. Here we take that heritage and apply it to Pre-Engineered automation solutions which allows us to focus our efforts on the areas that require customization such as specific process requirements, operator interface, work holding, and fixturing.

MESH offers a line of pre-engineered automation platforms that are customized for specific processes. In addition to these platforms, MESH has developed many process-specific “Bolt-On” modules that can be configured in a customized way to maximize the value of your automation solution. Click here to contact us and learn more about how one of our pre-engineered platforms can work for your processes.

The MACPal “OF”– is designed for robotic palletizing of mixed cases.

The MACPal is designed for robotic palletizing of cases, totes or bags.

The MACPac (MESH Automation Cell for case opening and packing) is a professional-grade, pre-engineered, robotics-based flexible automation cell.

The MACTend is a professional-grade skid-mounted tending cell designed for material handling and machine tending of small and medium-sized parts.

The MACLean is a line of equipment platforms designed for assembly processes in a small footprint.

The MACJoin is a professional grade skid mounted assembly platform designed for inserting joining aids such as rivets into small to large parts.

The MACStud2d (Gantry format for automated stud welding) is a professional-grade, pre-engineered, gantry-based flexible automation cell.

The MACStud3D (MESH Automation Cell for stud welding) is a professional-grade, pre-engineered, robotics-based flexible automation cell.

The MACMegaGrind is a professional grade finishing cell designed for finishing larger parts or where a heavier duty payload robot is required.

The MACGrind is a professional grade skid mounted finishing cell designed for finishing small and medium sized parts where process flexibility is paramount.

The MACControl is a highly functional and flexible robot cell controller with standard features and component specifications that rival today’s best industrial control systems.