High-Speed Robotic Tote Handling and Tote Palletizing

Reusable plastic tote bins and trays are a mainstay in many fulfillment centers and product distribution centers. Automatic handling of these totes and trays has many advantages and is proven to provide a good return on their investment.

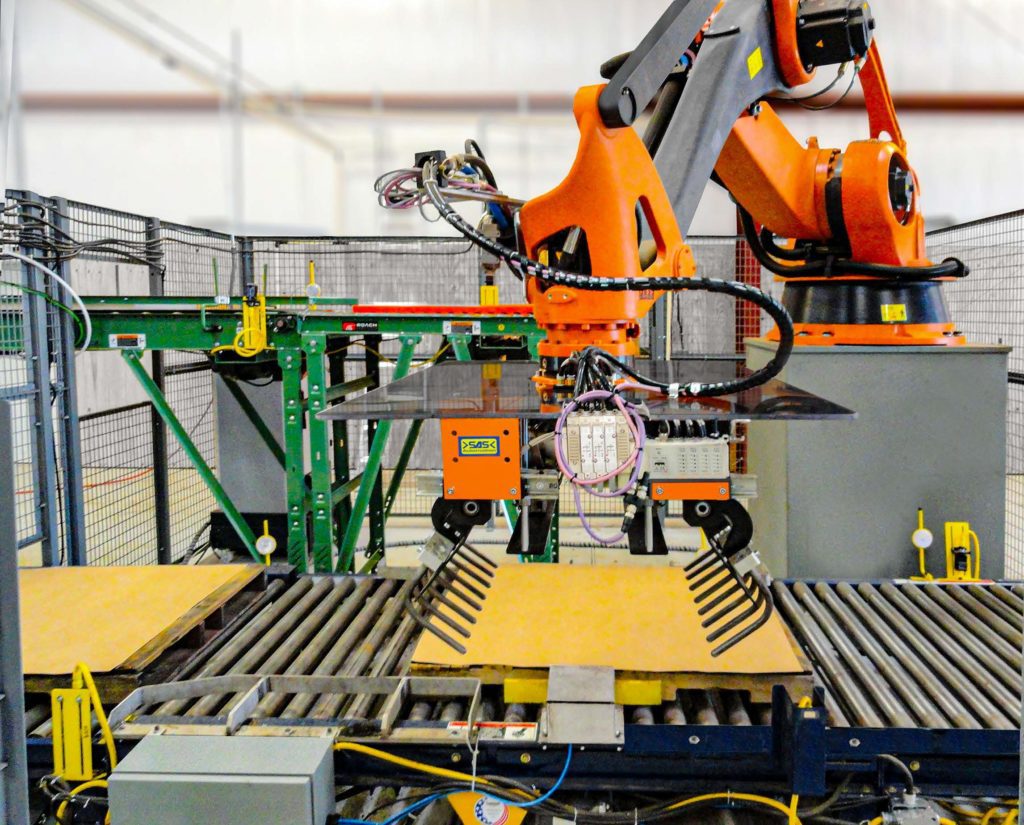

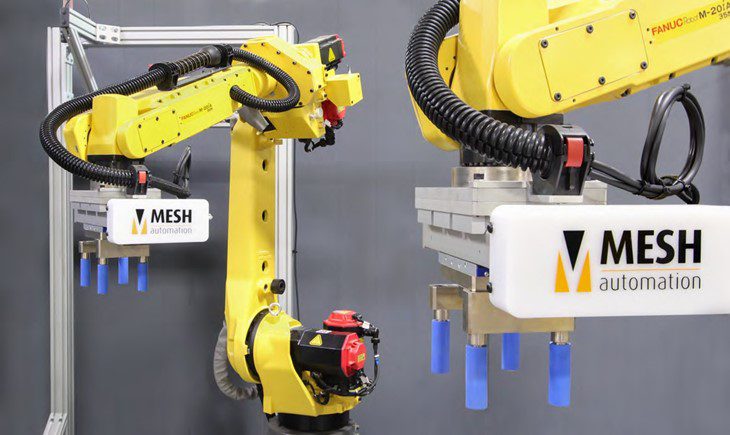

MESH Automation specializes in the design and manufacture of equipment that enables e-commerce sites, fulfillment centers, and distribution centers to transition from manual tote operations to fully automate handling, stacking, destacking, labeling, and palletizing. The benefits range from minimizing risks for employees to improved material handling and reduced running costs.

There is no doubt that many industries including food and beverage, life sciences, pharmaceuticals, and even high-technology sectors can cut costs and increase their efficiency with robotic tote handling options.

Benefits of Robotic Tote Equipment

If you’re wondering whether it’s worth installing a MESH tote handling system, the first thing to do is consider the many benefits. The fact is that tote stacking, de-stacking, and palletizing are often done manually, but because totes have a rigid structure, automated equipment can be used very easily to improve labor utilization. Experience matters in tote handling system design. MESH leverages its vast experience in robotics to provide competitive robotic tote/tray stacking, destacking, and palletizing systems.

Denesting certain totes and trays is difficult and often results in small injuries to your operators. Automatic systems for denesting/destacking totes and trays by MESH will solve those problems. Automation is ideal for most tote operations and can provide reliable and short returns on investment due to the repetitive nature of the tasks, ergonomic dangers to humans (weight and motion), forklift dangers, and sometimes seasonal labor availability issues. System design needs to be simple so maintenance can be easy to understand. Operator functions to unjam or clean up the area need to be taken into consideration, in addition to an intuitive operator interface or HMI. MESH has this experience and it shows in our equipment ruggedness and simplicity.

Tote labeling automation is paramount to a well-designed system. MESH can even offer a reusable laser write/erase label system to eliminate the cleaning process in most operations.

Robotic Tote Handling and Tote Palletizing Capabilities

The type of tote you use will depend on the industry you operate in. Totes are often used for e-commerce fulfillment, packing, order consolidation, and processes that influence the way traditional arm tooling and other traditional equipment works. Automated solutions are much more efficient, and the capabilities will be determined by your business operation.

- Tote stacking and destacking equipment function on one column of totes or trays. Denesting these can be difficult, but achievable with MESH’s solutions.

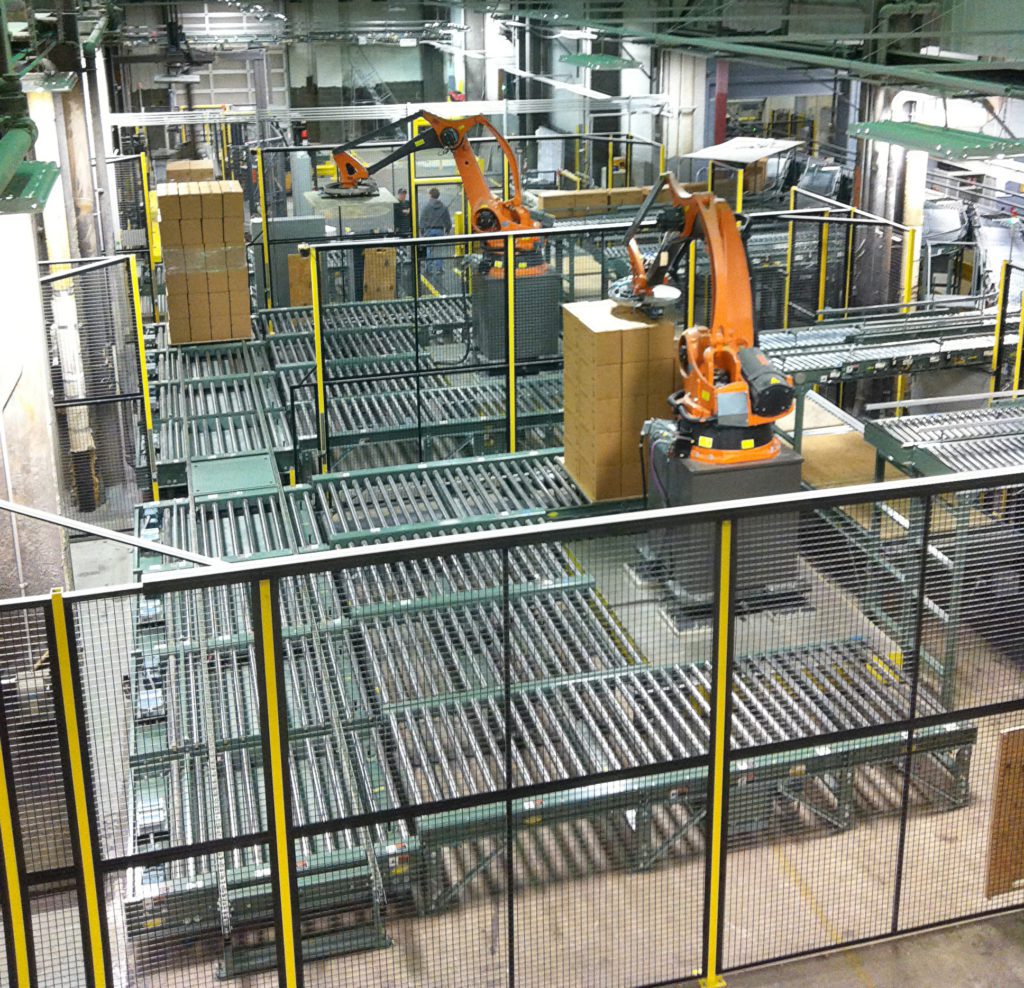

- Robotic tote palletizers by MESH can easily handle up to four infeed conveyors, their individual SKU, and up to four stacking locations in one cell. See our MACPal offering.

- Sortation is sometimes necessary for certain systems. Robotic palletizers can work seamlessly with sortation conveyors or dedicated lines from each production machine.

- Totes or trays per minute speed is usually the forefront of most specifications. It is best to consult with MESH sales and applications engineers to understand the productivity needs and options available. Robotic systems with their flexibility can typically perform at 3 – 4 times the rate of an operator, and they provide consistent throughput.

- Pallet stack height – Most modern palletizing robots if configured correctly can stack up to 108” tall.

- Pallet or stack envelope (length and width) – Most stacking configurations are designed to fit into a 48” x 40” envelope, but robots are very flexible and can easily accommodate most requirements within reason.

- Palletizing or Unitizing – Unitizing is stacking Totes or trays on a returnable sleigh board. Palletizing is stacking totes or trays on pallets that are included during storing and shipping. Consult with your MESH sales engineer for the pros and cons of each.

- Dunnage – With automatic slip sheet dispensers and the correct end effector MESH can accommodate most slip sheet requirements.

- Labeling on reusable tote systems is a headache as sticky labels build up over time and need to be removed. MESH can offer laser erasable and rewriteable rigid labels.

- Safety – MESH designs our robotic tote and tray stackers, destackers, and palletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia or Europe.

Tote Palletizing FAQ

What are the key reasons companies choose automatic tote and tray handling systems?

Labor issues are at the forefront of most automation decisions. Most manual tote handling jobs are high speed, resulting in repetitive motion injuries and are undesirable (hard-to-find workers). Human interaction with forklifts is an accident waiting to happen. Robots and other automation along the packaging line eliminate these labor issues forever.

What is the difference between a tote stacker and tote palletizer?

Automated tote and tray stackers are for single columns of totes or trays. In reusable systems, totes are typically columnar stacked at the end of their production cycle. Automatic palletizers will stack many totes per layer with multiple layers tall on a pallet or sleigh board. Full pallets of totes or trays are typically the finished goods product designed for the internal or external customer. Tote or tray stackers can use conventional automation techniques in addition to robotics. Tote or tray palletizers are best suited for robotic-only systems.