MESH Adhesive Lamination Lines

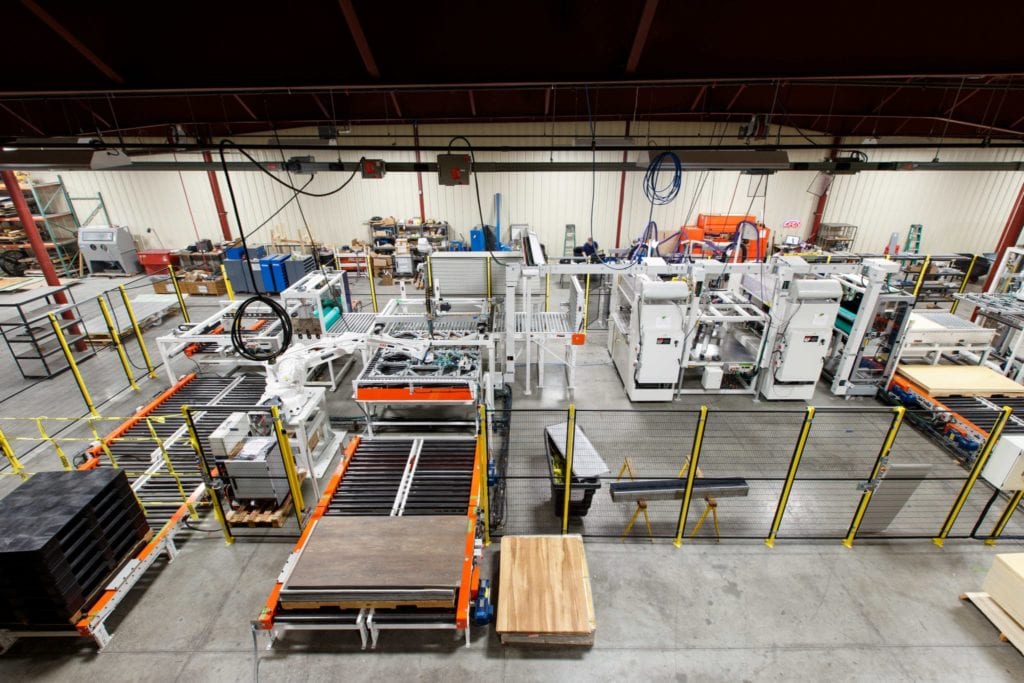

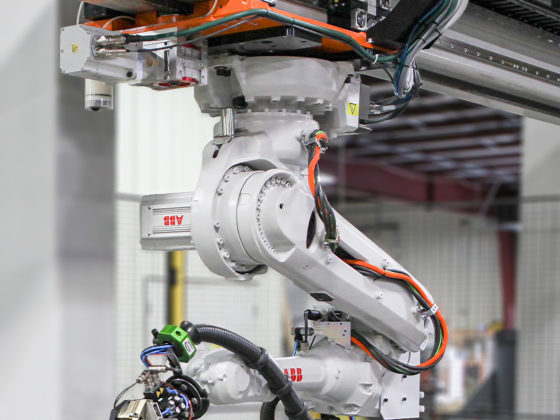

At MESH Automation, we are at the forefront of revolutionizing adhesive lamination lines across a multitude of industries, including flooring, doors, and other building products. Leveraging our cutting-edge picking and palletizing technologies, along with our profound expertise in glue system integration, we’ve crafted a comprehensive lamination and glue line solution unparalleled by any other North American company.

Innovative Adhesive Lamination Equipment

For years, the industry has relied on outdated methods for adhesive lamination, resulting in inefficient use of space and limited throughput. MESH Automation challenges the status quo with our flexible, modular machine designs. Our solutions occupy 50 – 75% less floor space than traditional models while delivering unmatched speeds and precision.

Advanced Roll Handling Capabilities

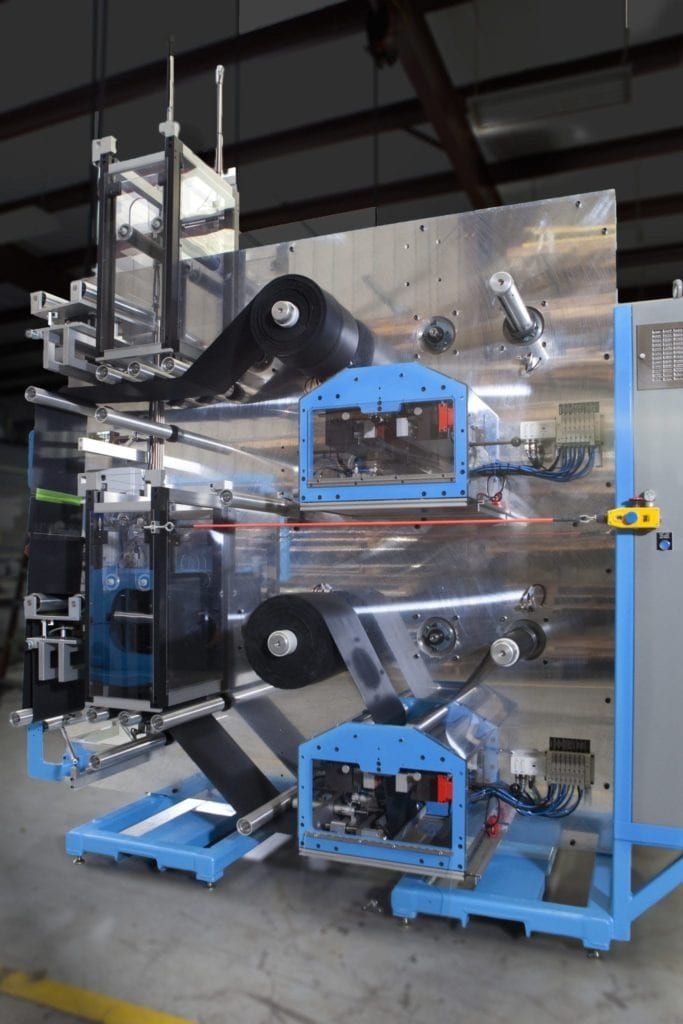

Our extensive experience in the high-speed converting market has equipped us with the knowledge to offer superior high-speed autosplice unwind systems. These systems feature web guiding for materials requiring unrolling, ensuring precise tension control, autosplicing, and web guiding.

State-of-the-Art Laminating

Our innovative approach extends to laminating, where MESH boasts multi-roll laminator designs available in various widths. These designs are not only cost-effective and robust but also highly flexible to meet diverse production needs.

Comprehensive Surface Cleaning

To complement our lamination lines, MESH provides surface brush cleaner modules in various widths, incorporating static elimination and vacuum heads alongside counter-rotating rotary brushes. This ensures thorough cleaning of both the top and bottom surfaces of the raw material.

Expert Adhesive Application

Our expertise in adhesive application is extensive, with a deep understanding of integrating roll coater and adhesive hot melt technologies from leading OEMs. Whether working with PUR or PSA adhesives, MESH has the experience and knowledge to meet your adhesive application needs.

At MESH Automation, we’re dedicated to delivering comprehensive, innovative solutions that enhance efficiency and productivity in adhesive lamination processes. Explore how our unique technologies and expertise can benefit your production line.