Medical device assembly automation and test and inspection are critical for manufacturers of a wide range of consumer healthcare and both medical and surgical products. Lean manufacturing processes are preferred because they are more efficient and potentially more profitable, and they enable companies to produce medical devices that are safe and effective. Factory automation speeds up systems and improves productivity, while machines developed for testing and ensure that all processes work in an optimal way.

Learn More About MESH Expertise In:

Non-Woven Converting Machines for Medical Devices and Supplies

MESH Machinery Retooling and Retrofitting for Non-Woven Material Medical Supplies

MESH and Medical Device Assembly Automation

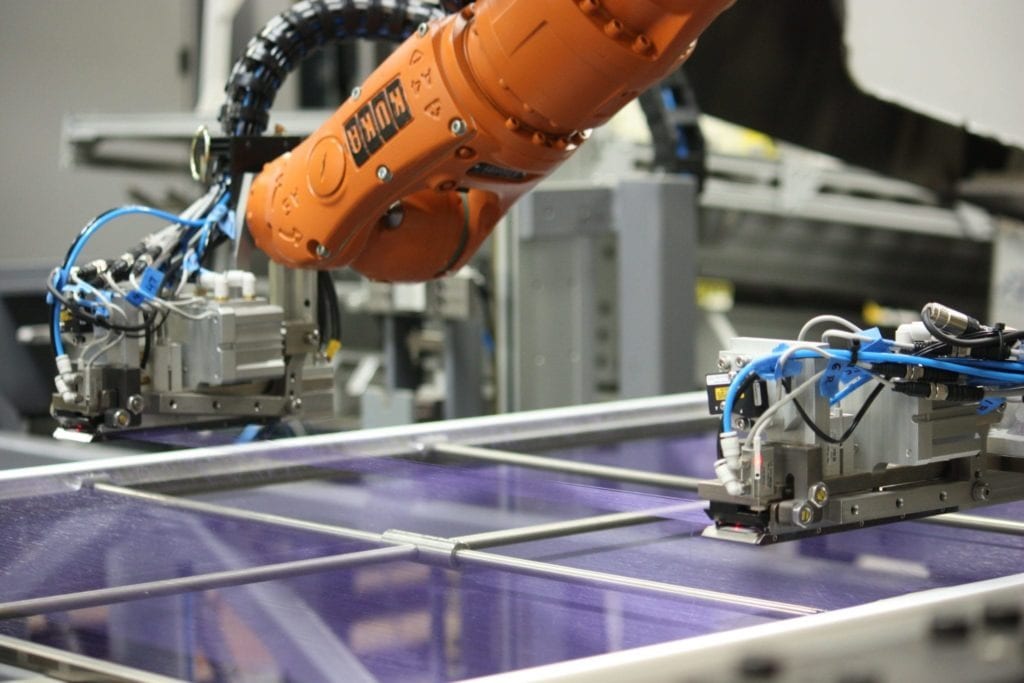

MESH Automation designs and builds the machines needed for automated assembly of medical devices as well as functional testing. Our manufacturing and testing solutions for medical devices and related products range from work cells that stand alone, to full-on turnkey product assembly lines.

We connect production equipment with all the other elements needed to ensure accuracy, reliability, repeatability and consistency, including integrating computer hardware and software, networking, data collection, and material handling systems. We also specialize in dispensing and dose counting, trigger mechanisms, pick and place, sorting, and serialization. This enables our valued customers to speed up time in the market in the best possible way.

MESH Automation handles everything from conveyance and calibration of parts to robotics and whatever is required to integrate handling systems for custom automation of machines used for the manufacture of medical devices and other healthcare products. We also make improvements to existing production assembly capabilities.

Our customers include manufacturers of medical device and diagnostic (MD&D) systems, healthcare products, and life science companies in the biotechnology, pharmaceutical, and biopharmaceutical industries.

MESH medical device assembly automation and test machines have been shipped for use all over the world. Our success lies in our unique capabilities in sequential assembly of all types including:

- Dial table format

- Inline indexers

- Walking beams

- Pallet-based transfer systems

Sequential assembly of this type is particularly successful for manufacturers who require assembly and test, track and trace of medical and surgical devices including:

- Handling and packing of sutures

- Roller bottle handling systems

Contact the experienced MESH Automation engineering team and we will work with you to find the best possible manufacturing solutions for your medical device and healthcare products.