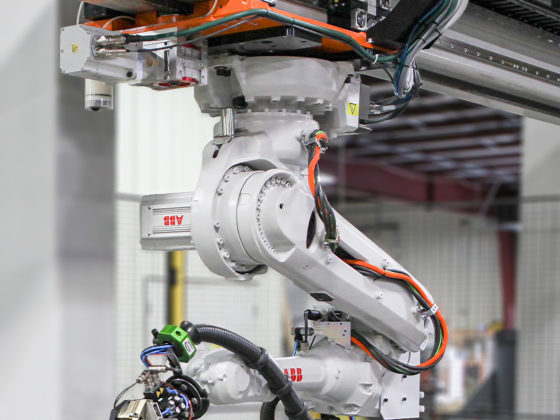

The MESH Automation Difference

Since 1999 MESH has strived to build and maintain our most valuable resource – our people.

We promote a work environment that is inclusive to all, professional, safe, and orderly that provides opportunities for personal and professional growth. Providing technically-correct automation solutions under the pressure of controlling both time and budget can be stressful at times, so the positive culture we employ at MESH is important to keep things in perspective for both the customer’s experience and our teams’ well-being.

This philosophy is what drives our equipment and system development.

The pride our people take in the equipment design, fit, finish, function and robustness is noticeable with the end result being systems that have longevity and beat their investment return promises.