Case Studies

Cobot Palletizing of Food Products

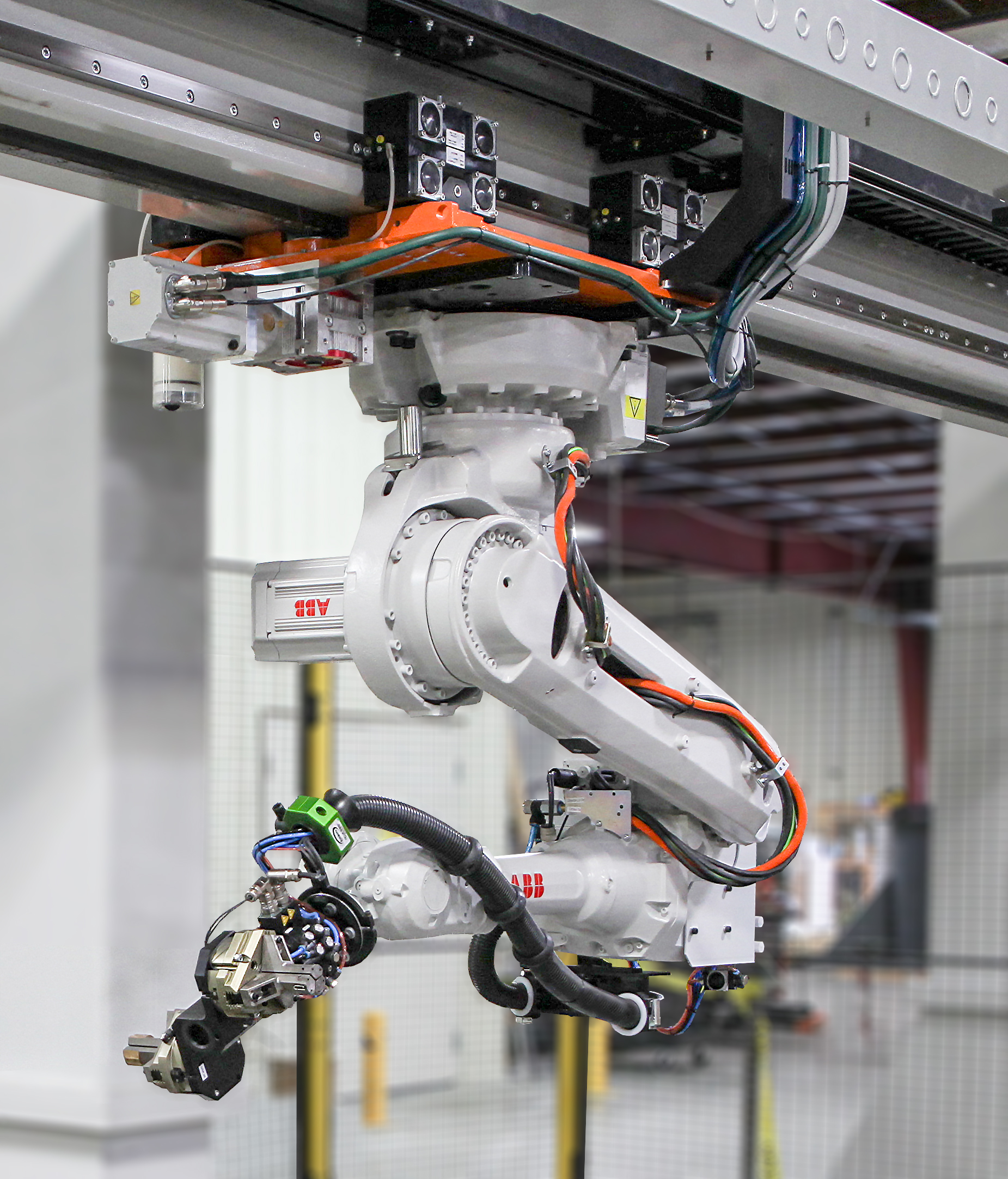

Robotic Grinding of Small Parts

Custom Robotic Load and Unload Cell

ROBOTIC LOAD UNLOAD OF RIVETING MACHINES

High Speed Robotic Bag Palletizing System

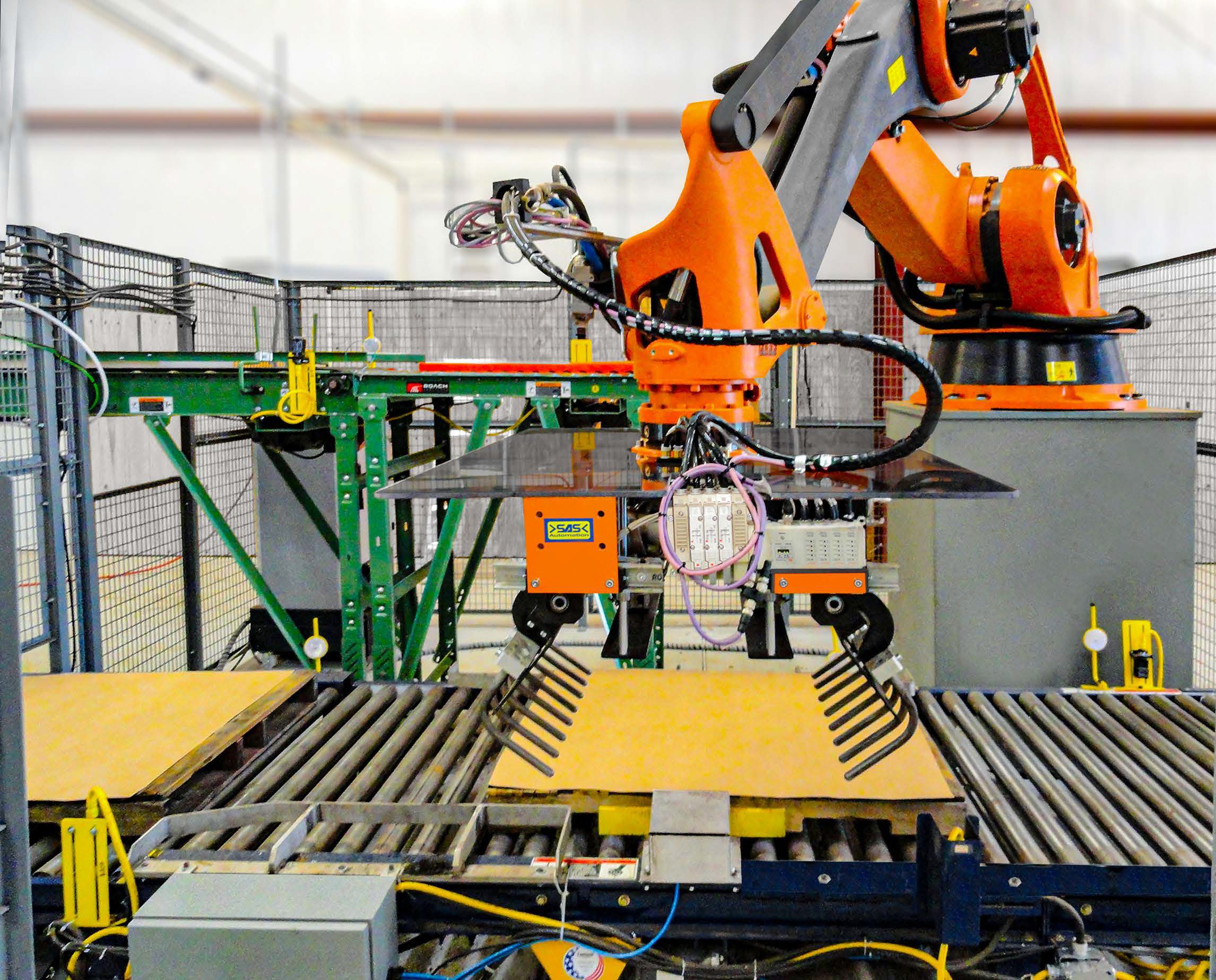

Palletizer for Rolled Roofing

Sort by Expertise