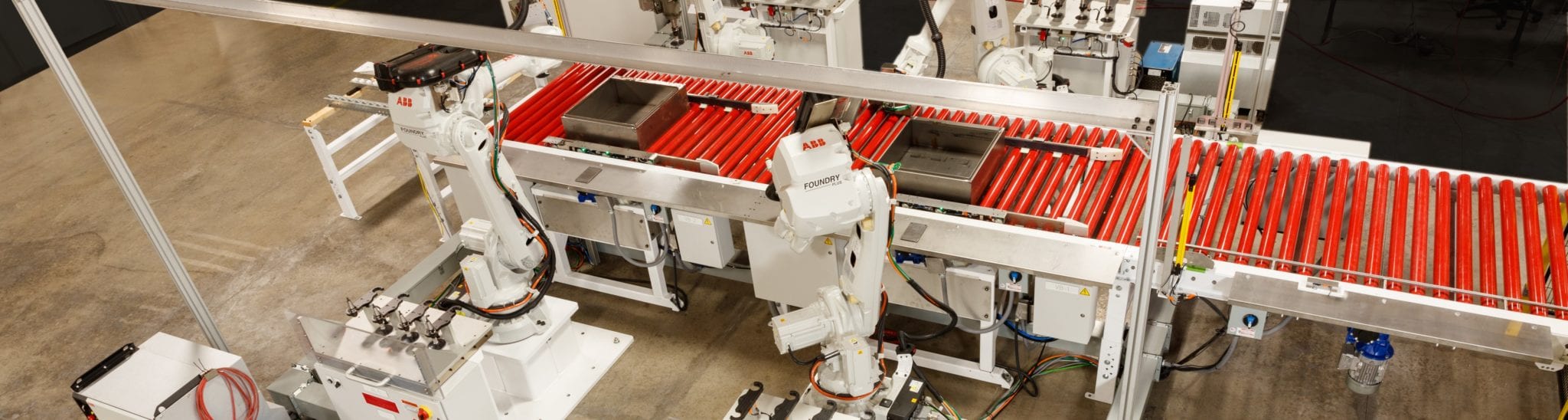

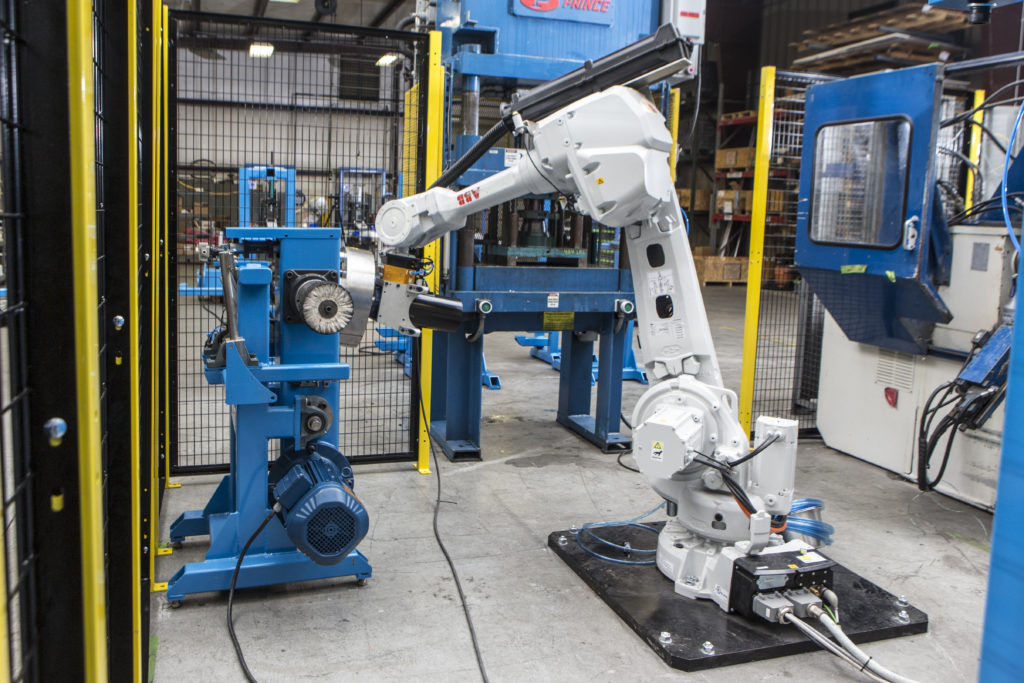

MESH Robotic Grinding, Machining and Finishing

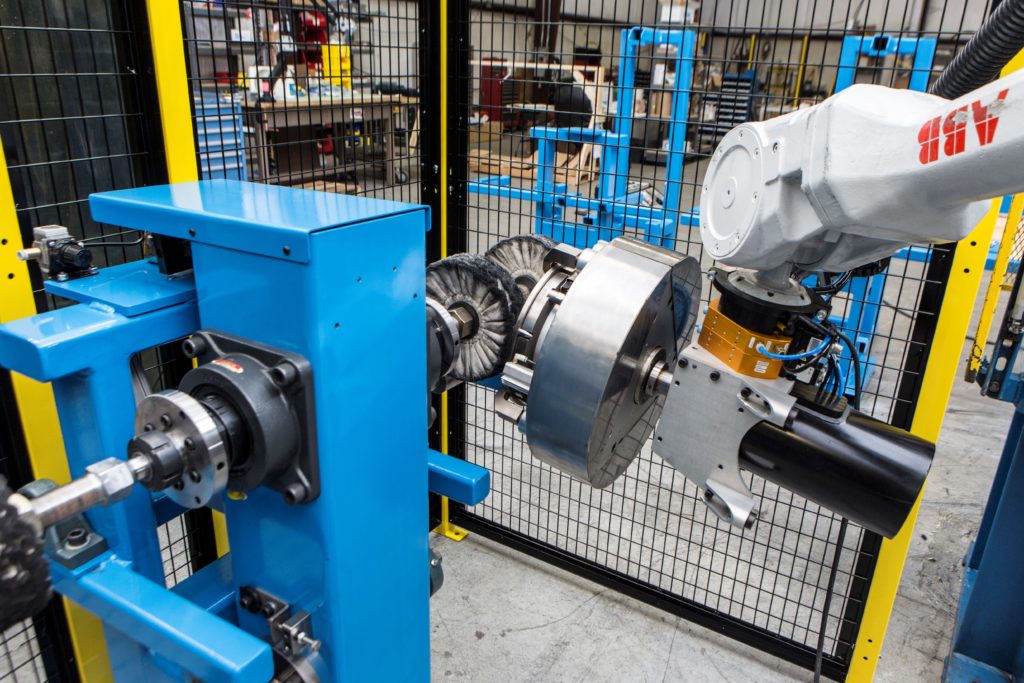

Material removal processes, including grinding, machining, and finishing, are often characterized by their physically demanding, dirty, and hazardous nature. This reality poses a significant challenge for manufacturers in attracting and retaining workers for such roles. However, the introduction of robotic systems offers a compelling solution to these challenges.

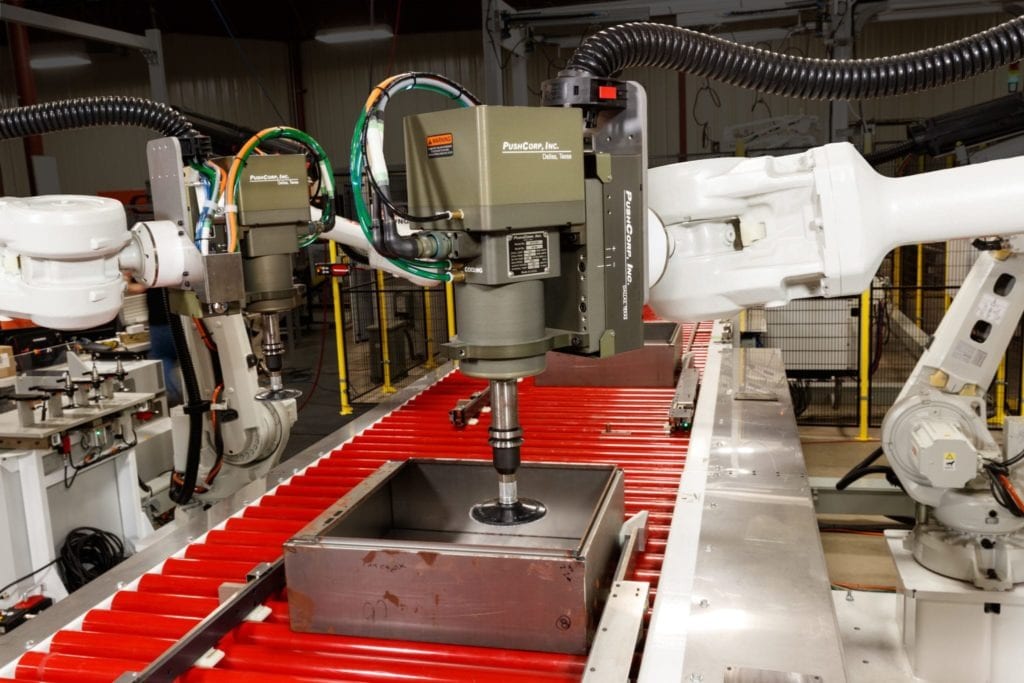

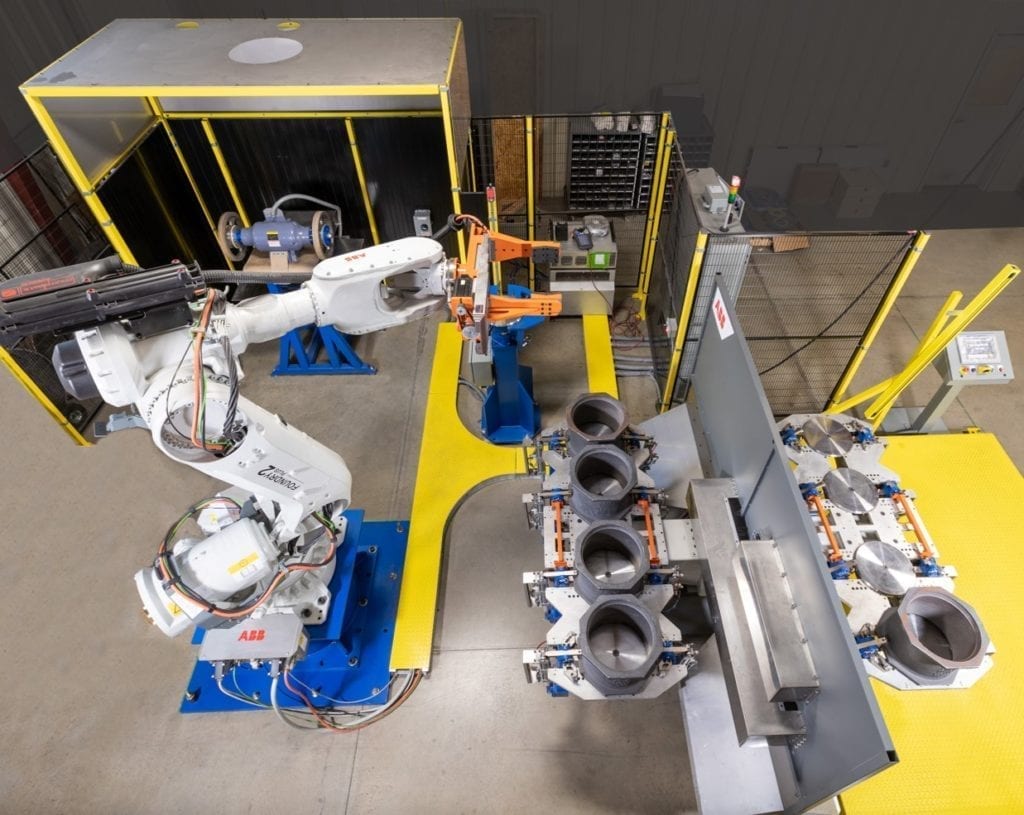

Robots excel in performing these tasks, capable of rapidly and efficiently removing excess material from machined or cast parts. Implementing robotics not only enhances production efficiency and reduces operational costs but also significantly mitigates the health and safety risks associated with manual finishing processes.

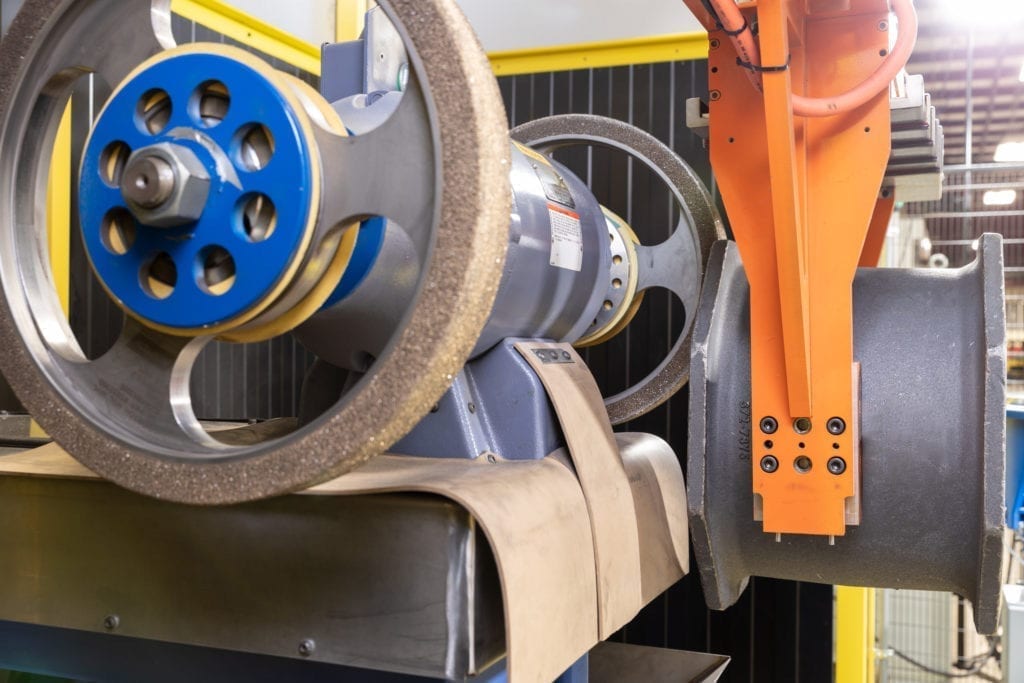

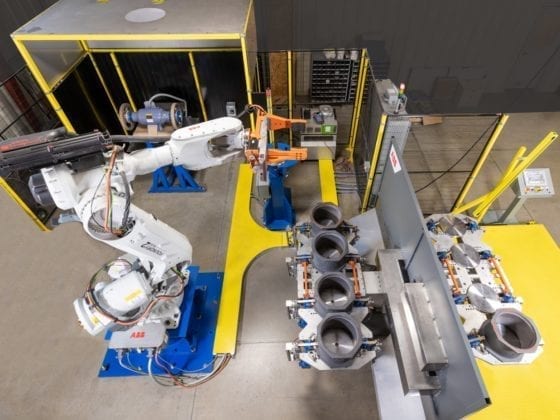

MESH Automation has designed and developed three distinct robotic platform solutions along with a variety of specialized “bolt-on” process modules. These modules are robustly engineered and equipped with advanced features, making them particularly suited for optimizing finishing processes. You can learn more about our pre-engineered finishing cells here.