MESH Automated Inspection Systems

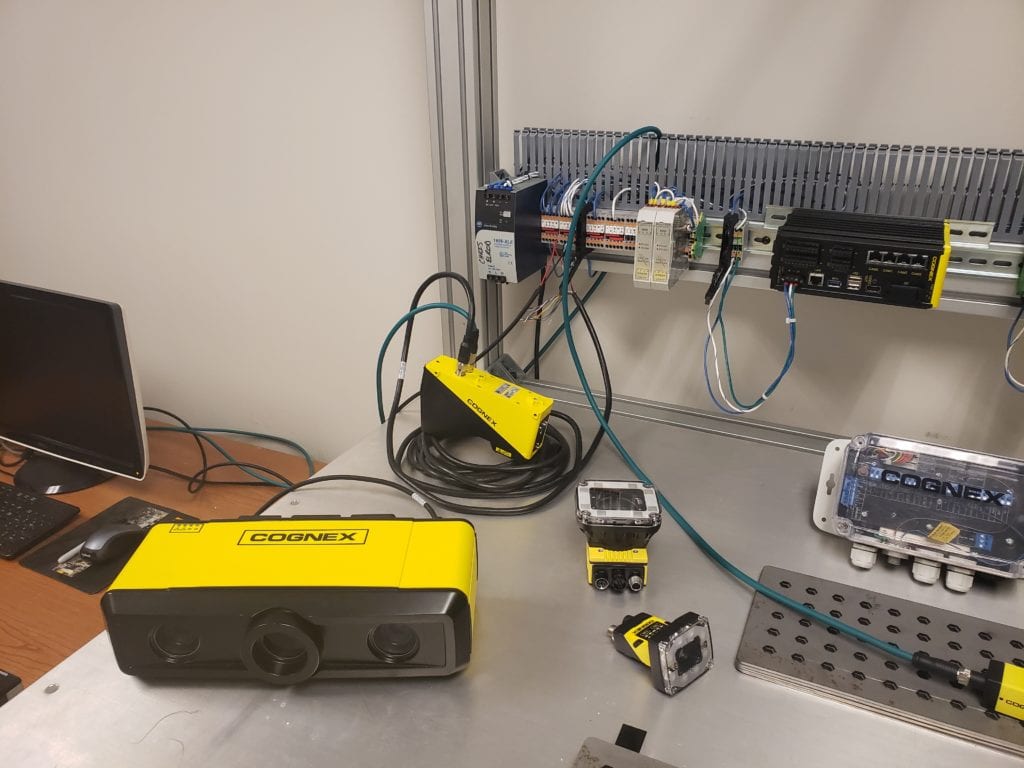

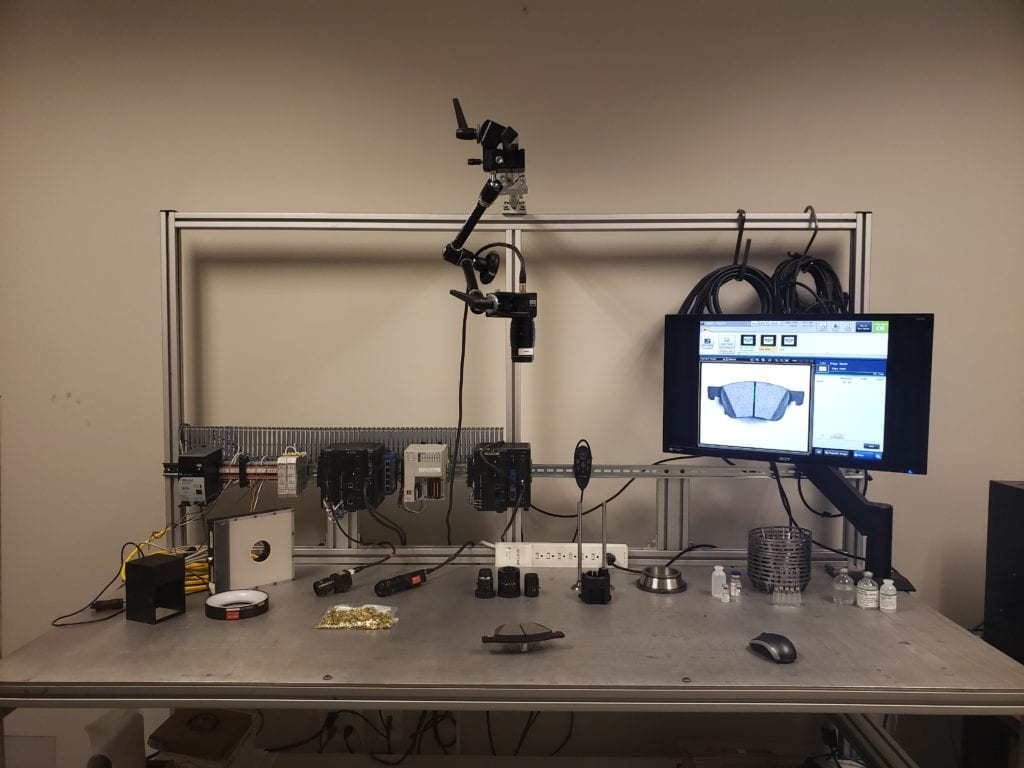

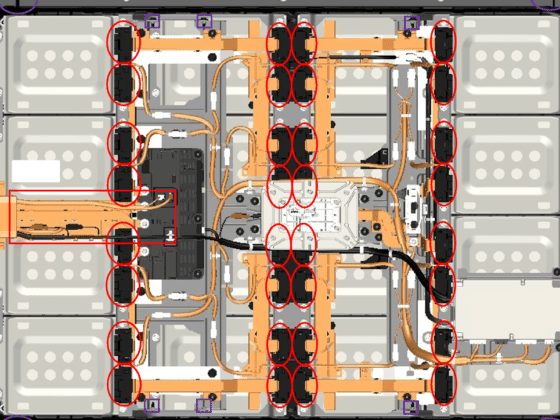

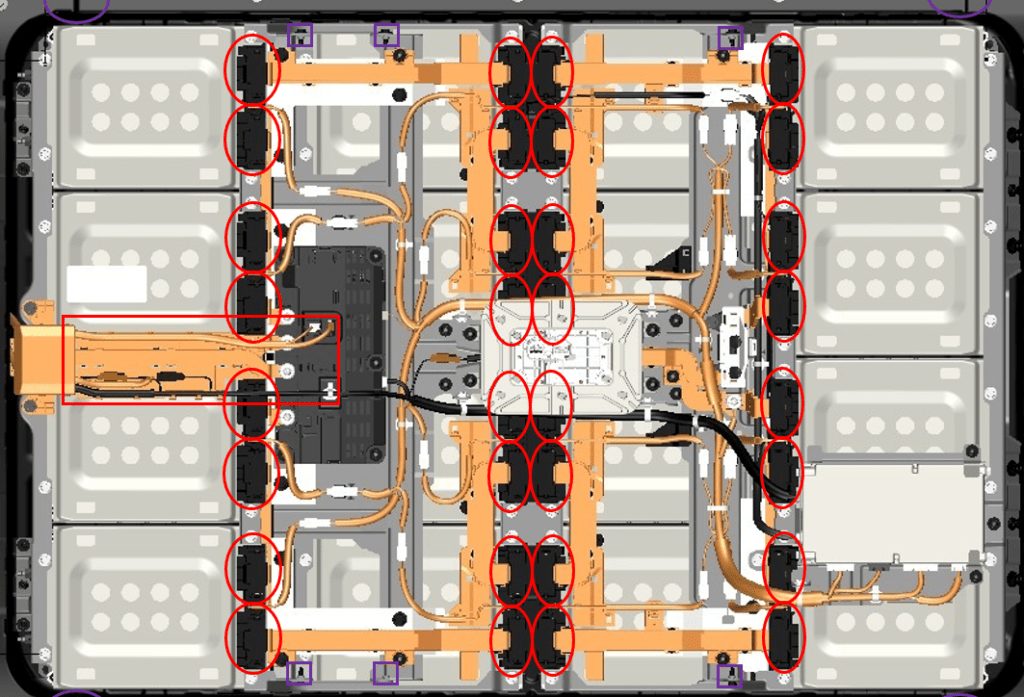

Our team at MESH Automation specializes in the design, construction, and programming of a broad spectrum of quality assurance solutions, including 2D and 3D vision inspection systems, non-contact laser measurement systems, tactile measurement tools, and advanced systems for mass flow or leak detection. We engineer these systems to be highly flexible, automatically adjusting to accommodate different products and fluctuating environmental conditions, effectively tackling your most challenging quality issues.

At MESH Automation, we deliver expert solutions in measurement, quality control, and marking/tracking. Whether integrating lasers, scribers, or print markers, we do so with unmatched professionalism. Moreover, marking is often followed by the need for precise tracking, an area where we excel, thanks to our comprehensive machinery and software capabilities.

Our dedicated in-house team, equipped with a state-of-the-art vision inspection lab and extensive resources, enables us to seamlessly integrate the ideal marking, tracking, and quality systems into your existing processes and equipment.

Additionally, we are capable of designing and building new automated or semi-automated machines that incorporate these systems, offering a complete solution to enhance your production efficiency and quality assurance.

MESH VISION & INSPECTION PARTNERS