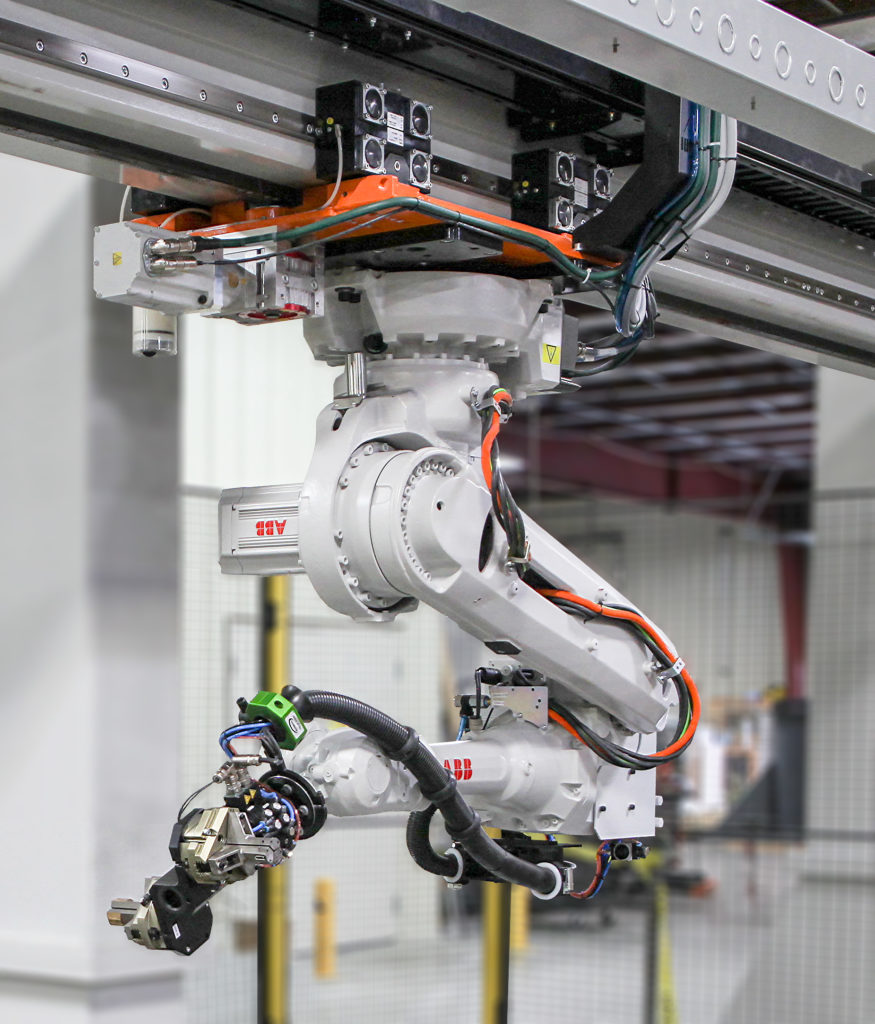

MESH ROBOTIC MACHINE TENDING FOR MANUFACTURING & TEST EQUIPMENT

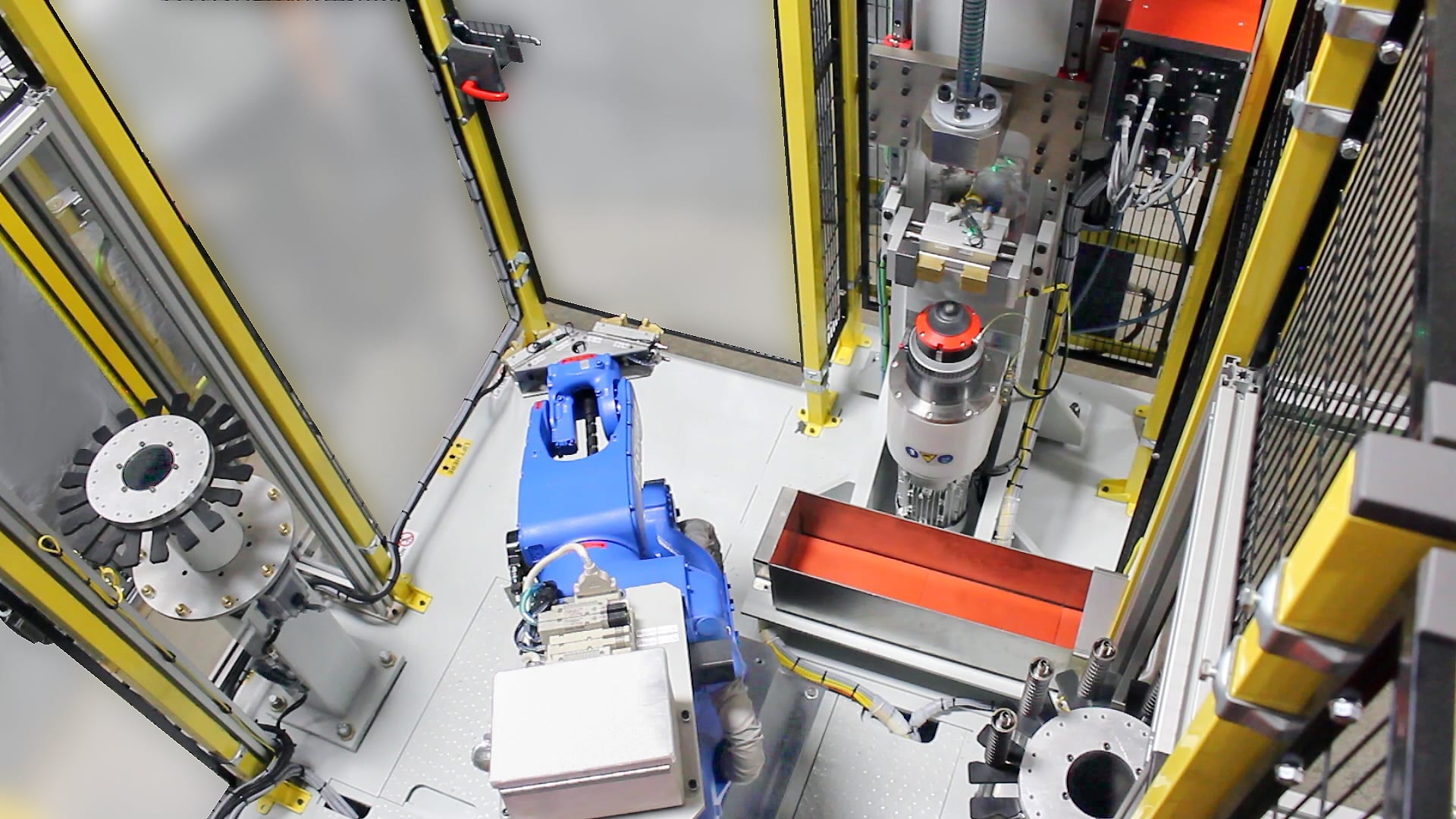

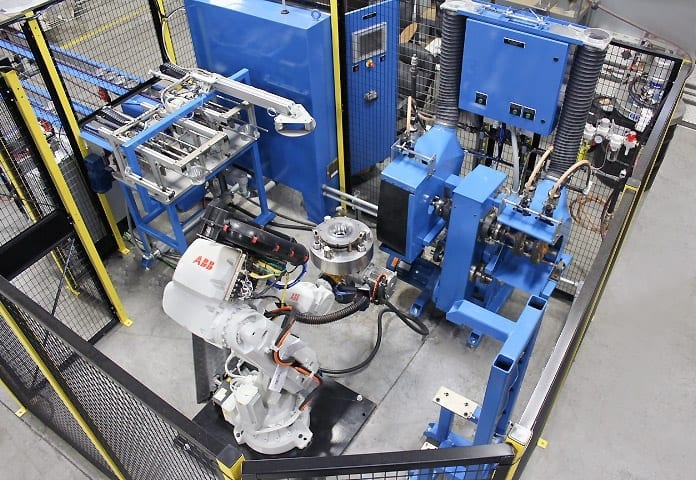

At MESH, we specialize in designing robotic tending systems for a wide range of manufacturing equipment, including brake presses, stamping presses, rivet formers, polishers, grinders, assembly cells, washers, fixtures, and more.

Our robotic automation solutions ensure seamless integration with the process equipment, maintaining throughput and preserving part integrity. From small plastic components to medium-sized pressure vessels, we have successfully completed numerous robotic tending projects with cycle rates ranging from 3 to 60 seconds.

When you partner with MESH, you gain access to our extensive robotic experience and specific equipment knowledge to enhance your next automation opportunity. Contact a MESH professional for a free analysis of your robotic machine tending and automation needs.

Benefits of Robotic Tending Manufacturing & Testing Equipment;

As with most robotic automation projects, the expected benefits are improved labor utilization, reduced scrap, improved safety, improved throughput, consistency of product, and production.

Machine tending is no different. The difference maker could be in the experience and expertise your system integrator provides. MESH Automation is a premier robotic integrator in the machine tending sector. Our experience is not one-dimensional either. We have completed over 100 machine tending applications in total with many special applications as shown below;

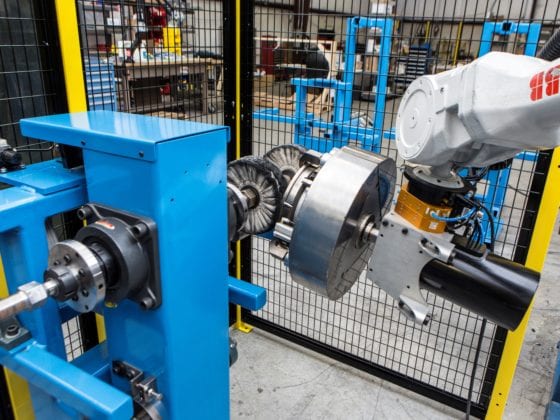

- High Voltage shed rod pull test

- Rivet formers for shock absorbers

- Brake pad load unload to assembly equipment

- Brake press tending for sheet metal products

- Buffing machine tending of light fixture reflective dome

- Polishing machine tending for 30 liter pressure vessels

- Fixture loading for stud welding and gas welding

- 30 liter pressure vessels into a helium leak tester

- Consumer Electronic products into grading and testing machines

- Industrial machined parts into QC drawers

- High pressure tanks into a weld analyzer

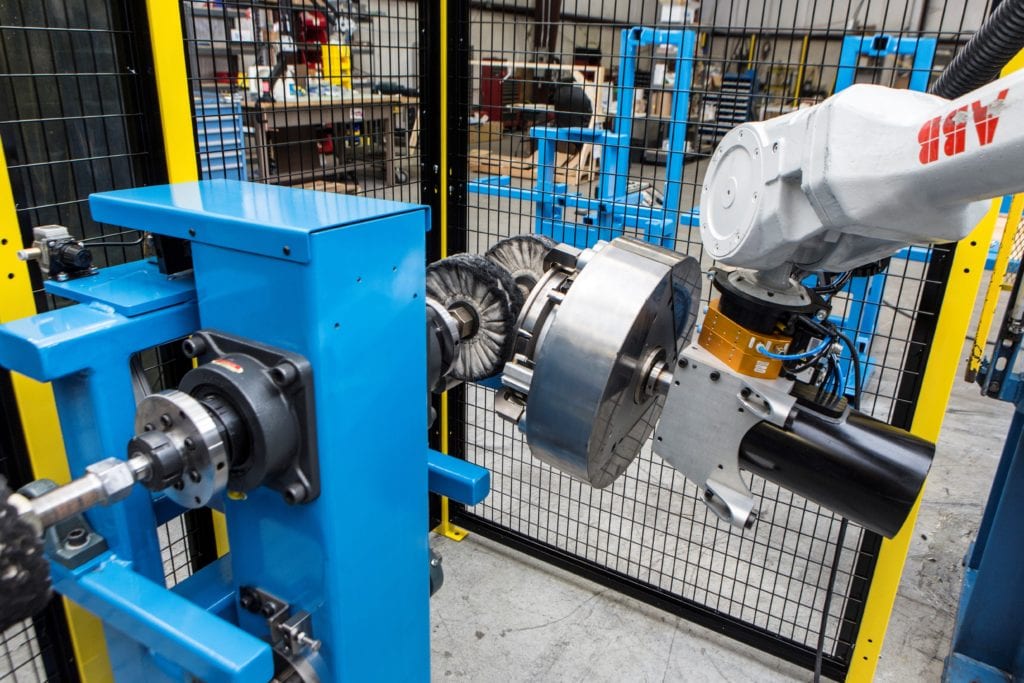

- Rotary seals and valves into mass flow leak test equipment

- Robotic laser scanning of the product dimensions

- Robotic presentation of the part to quality inspection cameras

Capabilities of Robotic Tending of Test & QC Equipment;

- With the clever use of dual end of arm tools, robot path optimization and regrip stations a MESH designed robotic tending system can optimize the process by keeping the process equipment loaded as much as possible. Cycle rates are usually process equipment constrained.

- Robots allow the part to be treated as gently as needed or to remain in a specific orientation. Plus tricky approach angles if needed can be accomplished.

- Part presentation or material handling to and from the robotic tending cell is standard and quite frequently pre-engineered at MESH.

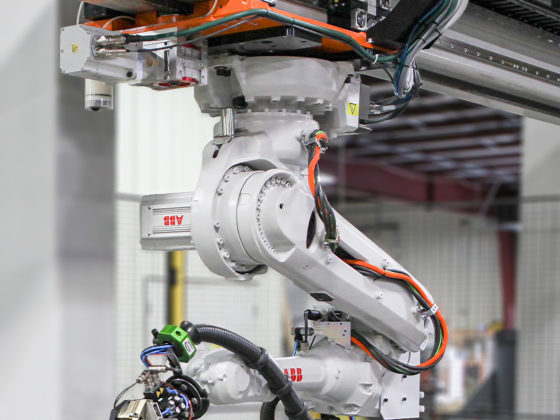

- Cobots in the right circumstances can be ideal tools for machine tending. Payloads of 30kg or under with 1.8meter reach are the current limits.

- Safety – MESH designs our robotic case depalletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

FAQs

What Type of robot is ideal for use in machine tending of test and QC equipment?

Cobots, Scara and six axis industrial robots have all been used for machine tending. Your MESH professional can advise you of the best robot for the task.

Is it important for the robot integrator to be knowledgeable of the test equipment function?

Yes a complete understanding of the test or QC equipment function is needed for the best tending application to be designed.