MESH CNC Load and Unload

Why MESH – Experience counts. Whether we are creating an engineered solution specific to your needs or supplying one of our ready now machine load/unload systems, the MESH team brings knowledge of machine tools, robotics, fixturing and tooling to each machine tending project. We have interfaced with many makes and models of CNC machines – old and new.

Why Robots – Robots and cobots provide a unique opportunity to automate one machine, several machines and to incorporate gauging, washing, marking and deburring into one productive workcell. With every touch of the part, the robot adds value to the part and the process. Consistency, reduced work in process, quality checks of key points early in the process all provide solid value to you.

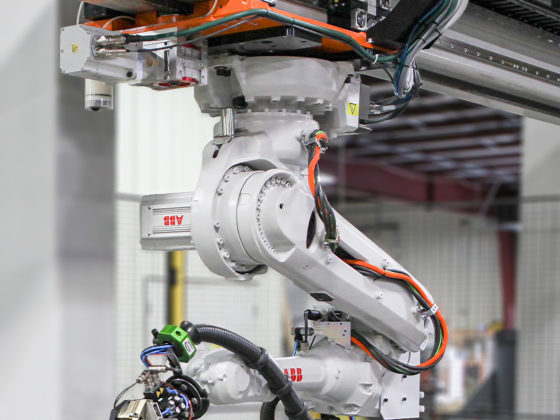

Leverage MESH’s experience – MESH Automation offers six-axis robot, cobot and gantry style robotic loading solutions for automation of machine tools and has completed a variety of projects. With hundreds of machine load/unload projects completed, MESH brings the upfront analysis skills that are needed to optimize your investment and the commissioning talents required to deliver a working solution that meets or exceeds your ROI expectations.

Benefits of Machine Tending for Mills and Lathes

The expected benefits of Robotic machine tending systems are improved labor utilization, reduced scrap, improved safety, improved throughput, consistency of product and production. The difference maker could be in the experience and expertise your system integrator provides. MESH Automation is a premier robotic integrator in the machine tending sector. Our experience is not one dimensional either. We have completed over 100 machine tending applications in total with many special applications as shown below;

- Aluminum wheel hub turning, drilling, tapping, pressing, and marking, from as-cast to completed hub machining and assembly.

- Truck brake drum turning and drilling load/unload systems.

- Pinion and gear blank processing; both loading of soft gear cutting and turning operations, as well as hard turn dimensioning, straightening and quality checking.

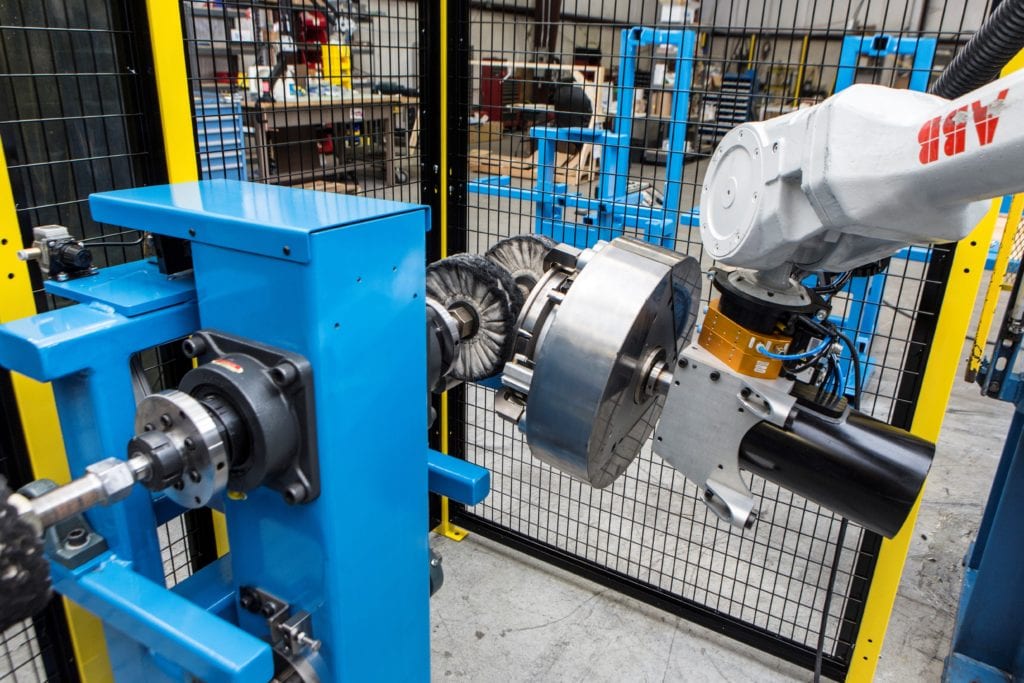

- Loading and unloading, gauging and pack out of flywheels, pulleys, CV joints, and axles.

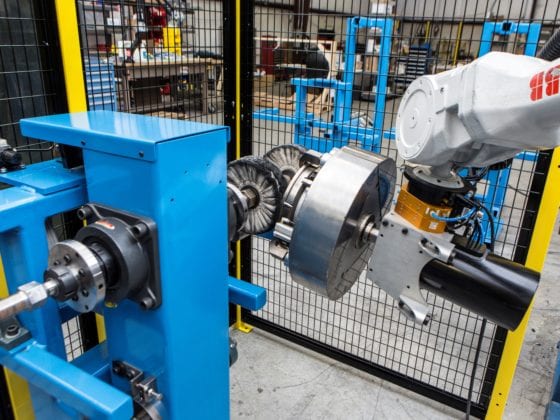

- De-burring of steel pinions and gears, pump impellers, cast aluminum power steering pump bodies and rifle receivers.

- Load and unload of differential carriers including washing and marking.

- Load and unload of trailer hitches with post milling de-burring and marking.

- Load and unload of bearings and bearing housings.

Let our automation engineers help you design the perfect solution today!

Capabilities of Machine Tending for Mills and Lathes

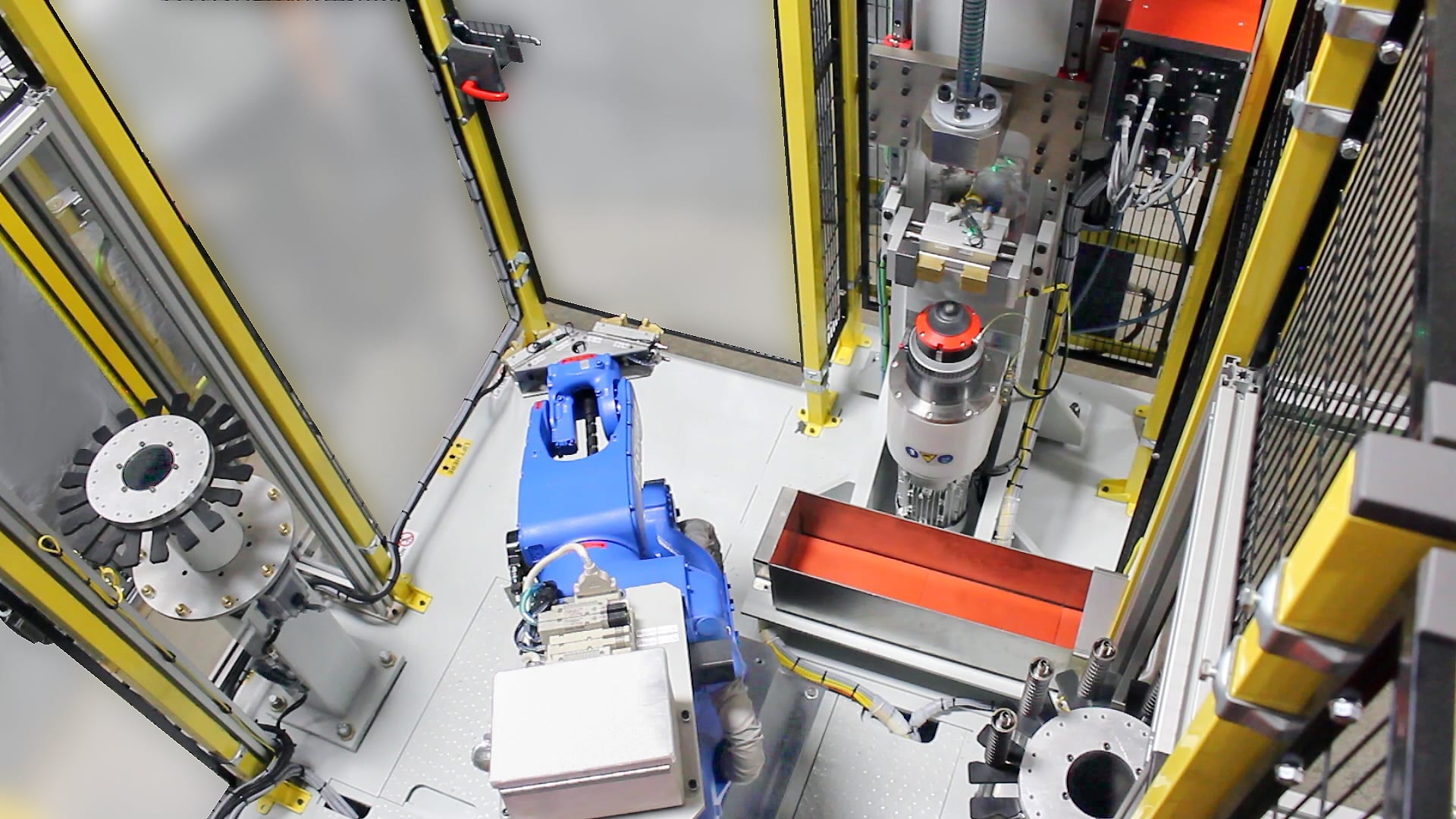

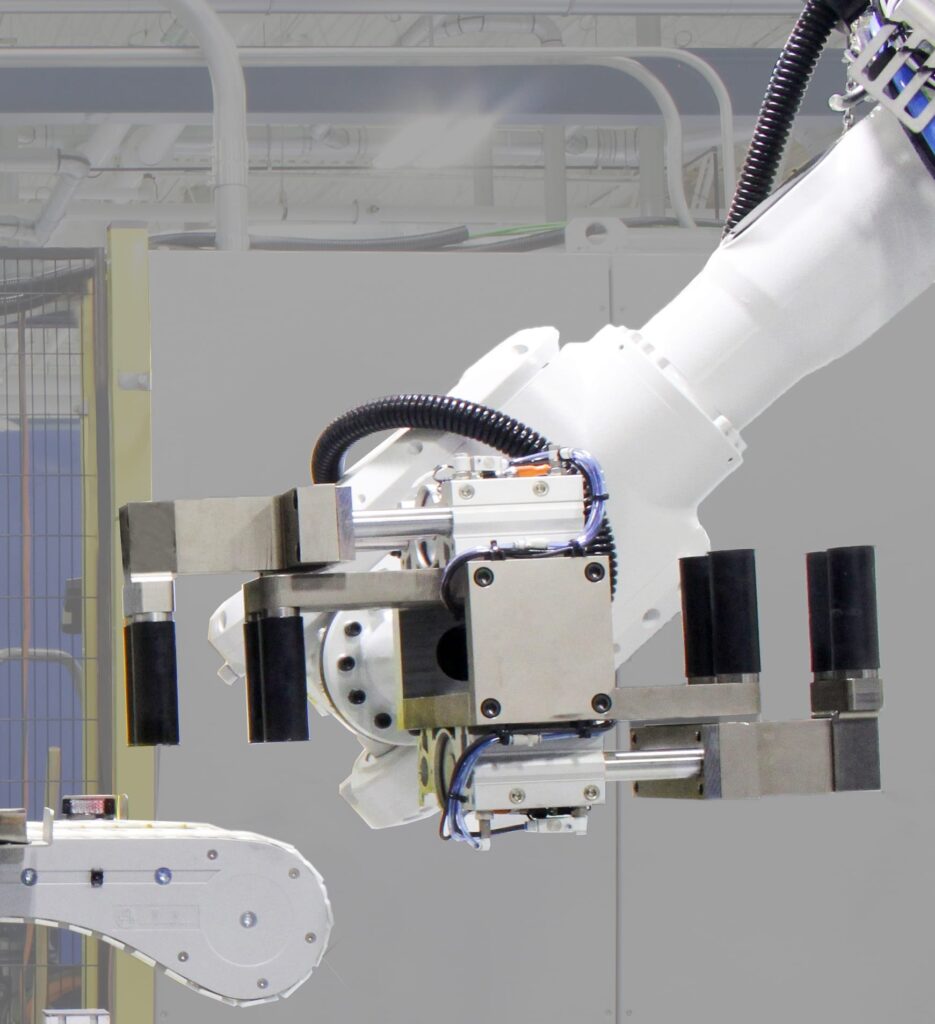

- With the clever use of dual end of arm tools, robot path optimization and regrip stations a MESH designed robotic tending system can optimize the process by keeping the equipment loaded as much as possible. Cycle rates are usually equipment constrained.

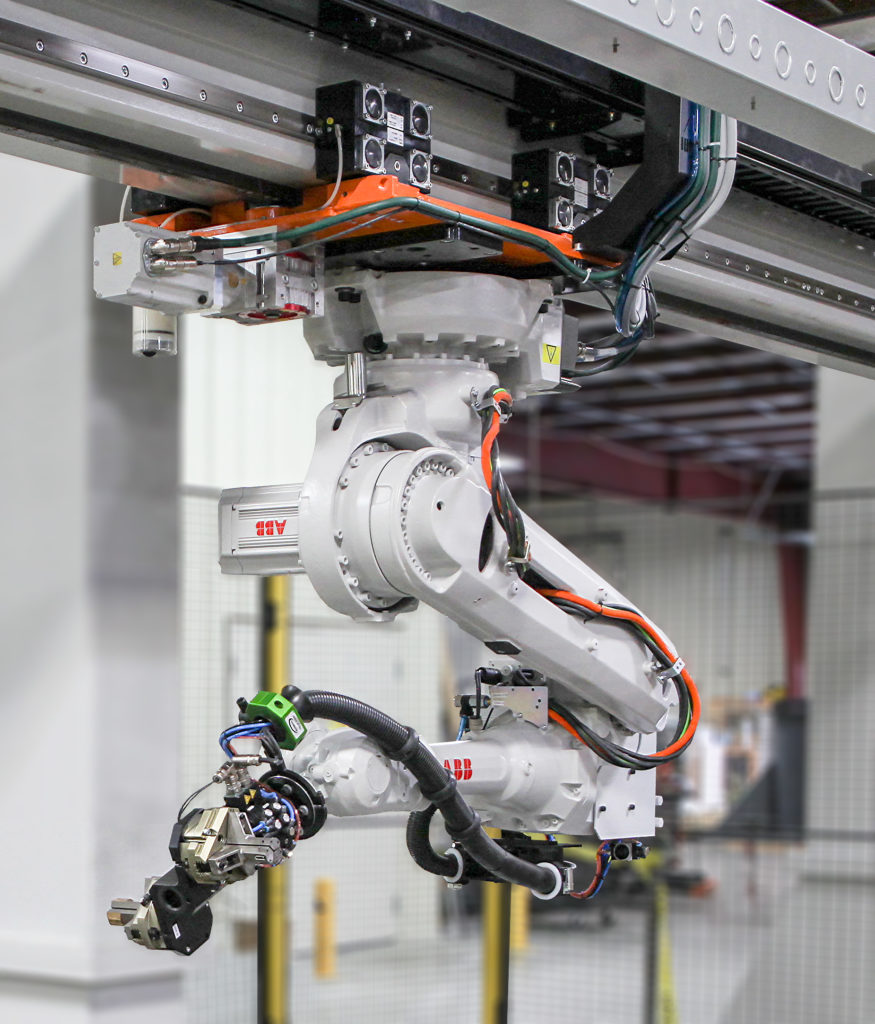

- The expert use of a robot transfer unit can save capital cost if the machining cycles are long and allow for one robot to tend multiple machines. These robot transfer units can put the robot in the air inverted to save floor space if needed.

- Robots allow the part to be treated as gently as needed or to remain in a specific orientation. Plus trickly approach angles if needed can be accomplished.

- Part presentation or material handling to and from the robotic tending cell is where the experienced integrator excels. MESH has many types of material handling solutions that are mechanical in nature plus vision guided solutions.

- Cobots in the right circumstances can be ideal tools for machine tending.

- Auxiliary equipment such as shown below are frequently needed in machining cells.

- Part-marking stations

- Part washers

- Robotic de-burring, de-flashing, and surface cleanup solutions

- De-palletizing and palletizing sub-systems for both dunnage and divider board approaches

- Gauge stations

- Drill stands

- Interface – MESH has the experience and contacts with the OEM to get the robot interface correct and running smoothly.

- Harsh environment – MESH incorporates features in our robot path design and our hardware that help with cutting fluid and chip problems and other harsh environmental factors typical to a machining center.

- Safety –Use of automatic door kits, permit to entry man doors, scanners and light curtains can all be part of the overall safety system as designated by the properly completed risk assessment.

CNC Machine Load and Unload FAQ

What type of robot is ideal for use in machine tending of machining centers?

Cobots and six-axis industrial robots have all been used for machine tending. Your MESH professional can advise you on the best robot for the task.

Is it important for the robot integrator to be knowledgeable of the equipment function?

Yes, a complete understanding of the equipment function is needed for the best tending application to be designed.