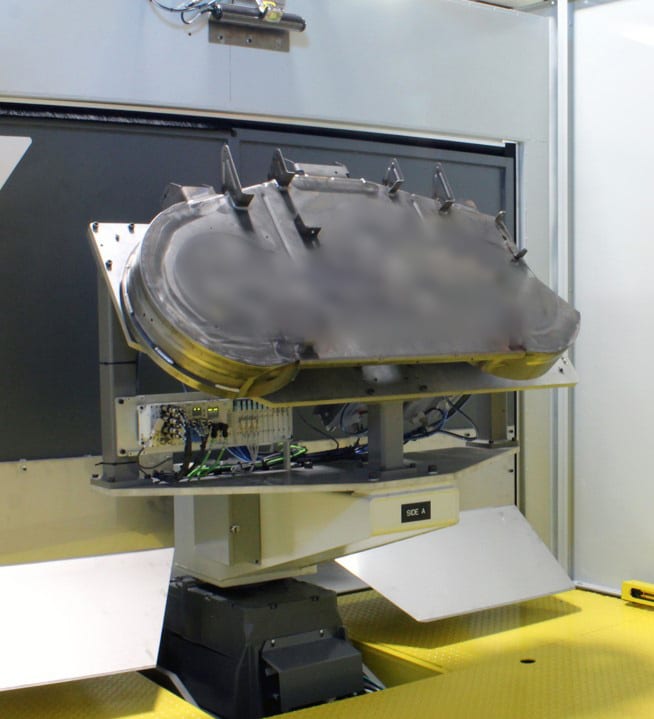

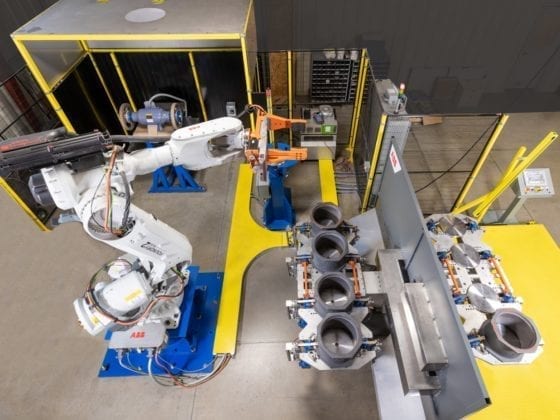

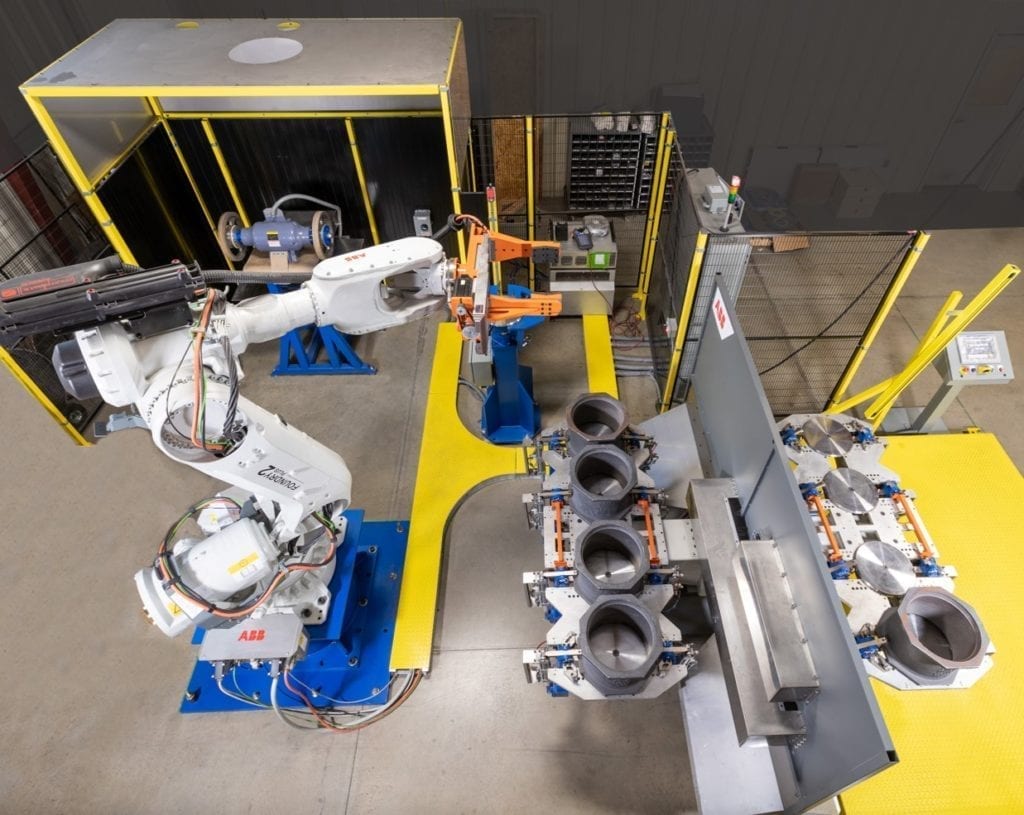

MESH ROBOTIC GRINDING AND BUFFING SOLUTIONS

Material removal is one of the most unpopular jobs in manufacturing. It is generally hard, heavy work that is also dirty and hazardous. For this reason, manufacturers struggle to get workers to fill positions that involve grinding, deburring and finishing. But robots can do these jobs exceptionally well, removing excess material from machined or cast parts quickly and efficiently. Not only will a robot save production time and reduce overall costs, it will also reduce the serious health and safety risks associated with particles getting into workers’ eyes and metal dust penetrating the lungs.

Robots are programed to apply just enough pressure for the job, so that the integrity of each piece is retained and all work pieces kept beautifully uniform. If there isn’t enough pressure, time and materials are wasted, while too much pressure can ruin a part. With properly programed force control a robot will always maintain a constant force while deburring, buffing and polishing, unlike a human who while flexible, is not consistent.

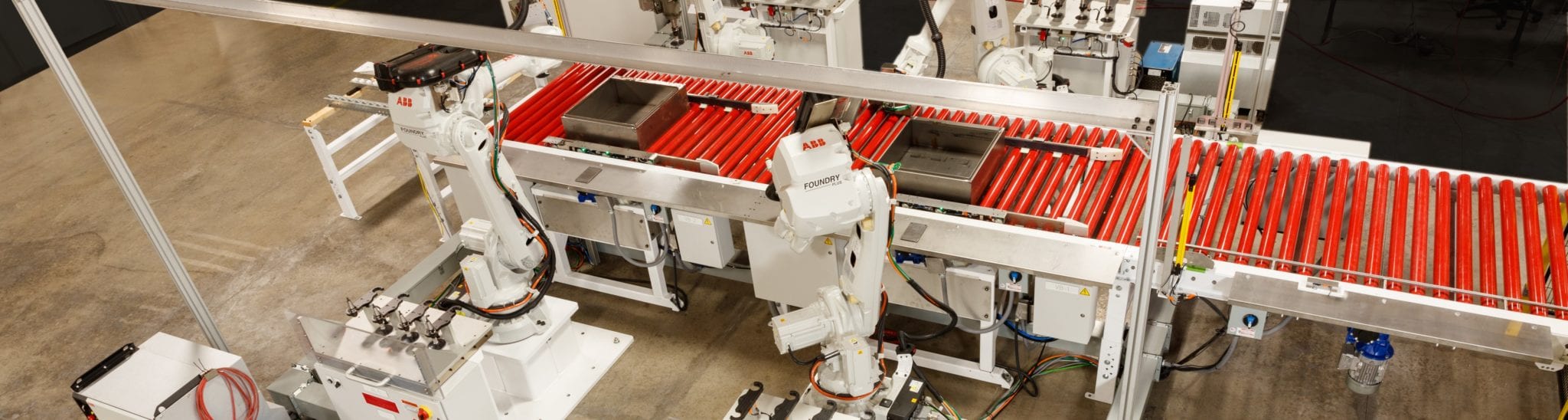

MESH Solutions for Robotic Grinding and Finishing

The MESH engineering team has extensive experience with all the applications that relate to robots in general and robotic grinding and buffing in particular. We use our experience to establish the best solutions for the varied challenges of our individual customers.

When building automation cells or systems that will suit your needs, we use all the tricks of the trade we have learned over time.

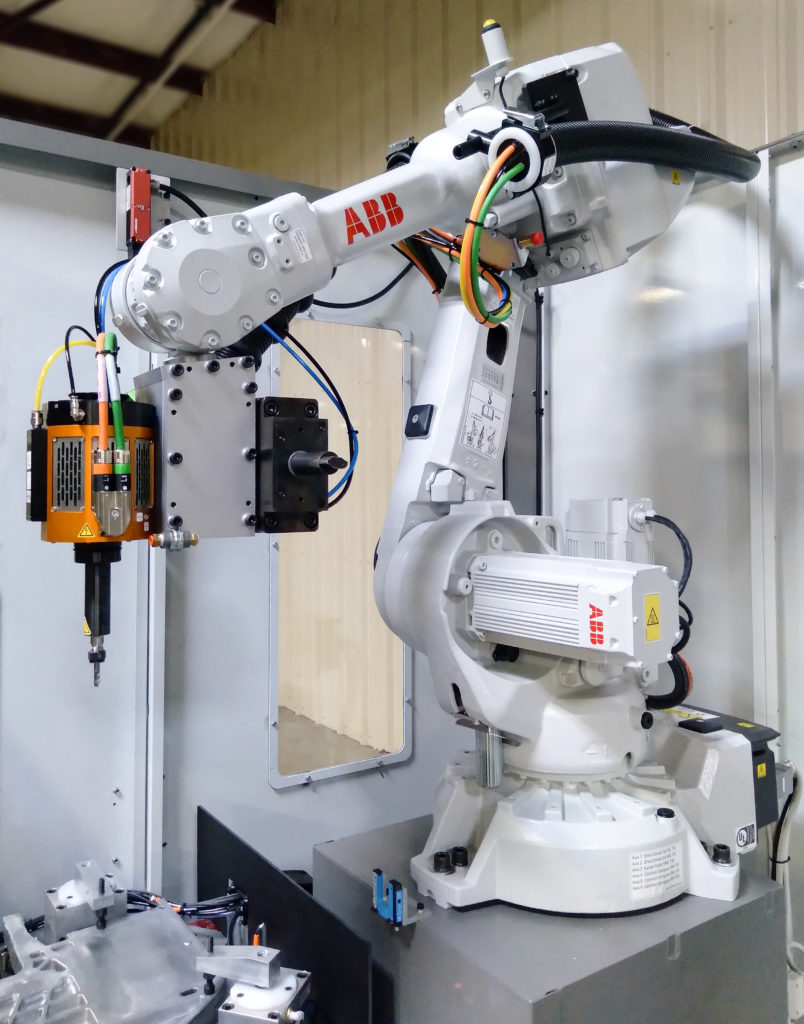

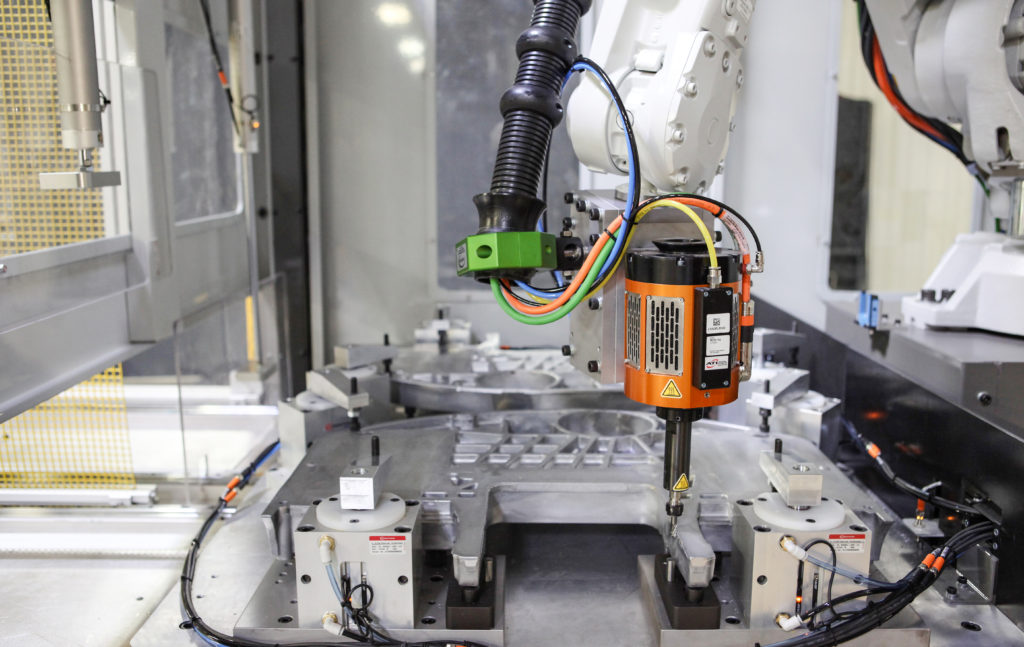

We will build the:

- End-of-arm tools and fixtures

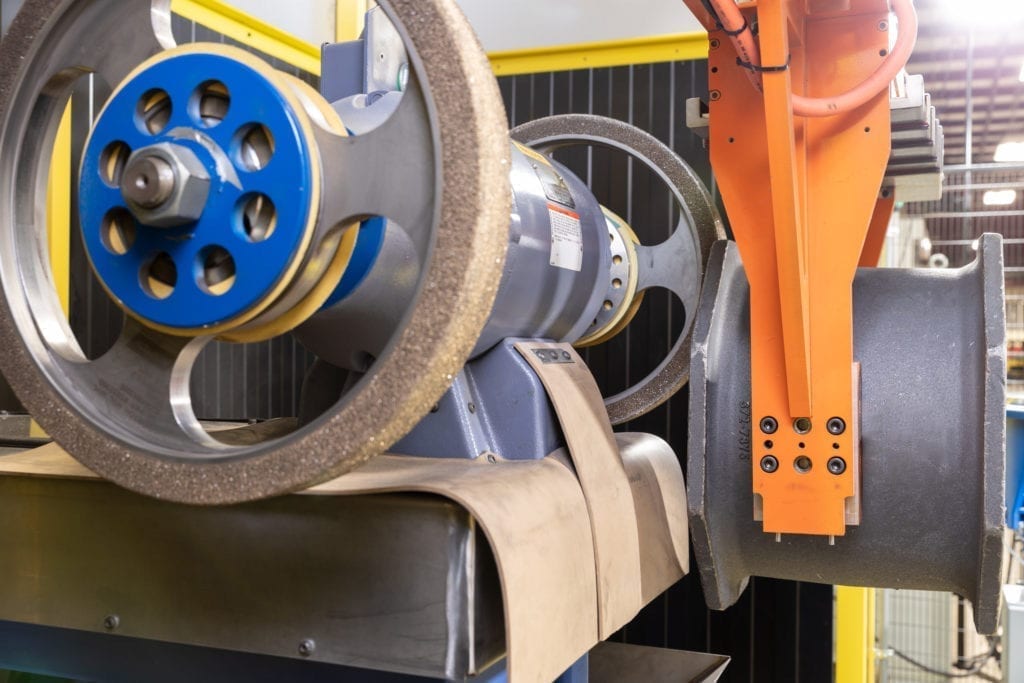

- Fixtures, regrip stands and compensated backstands

- Grinding tools and belts

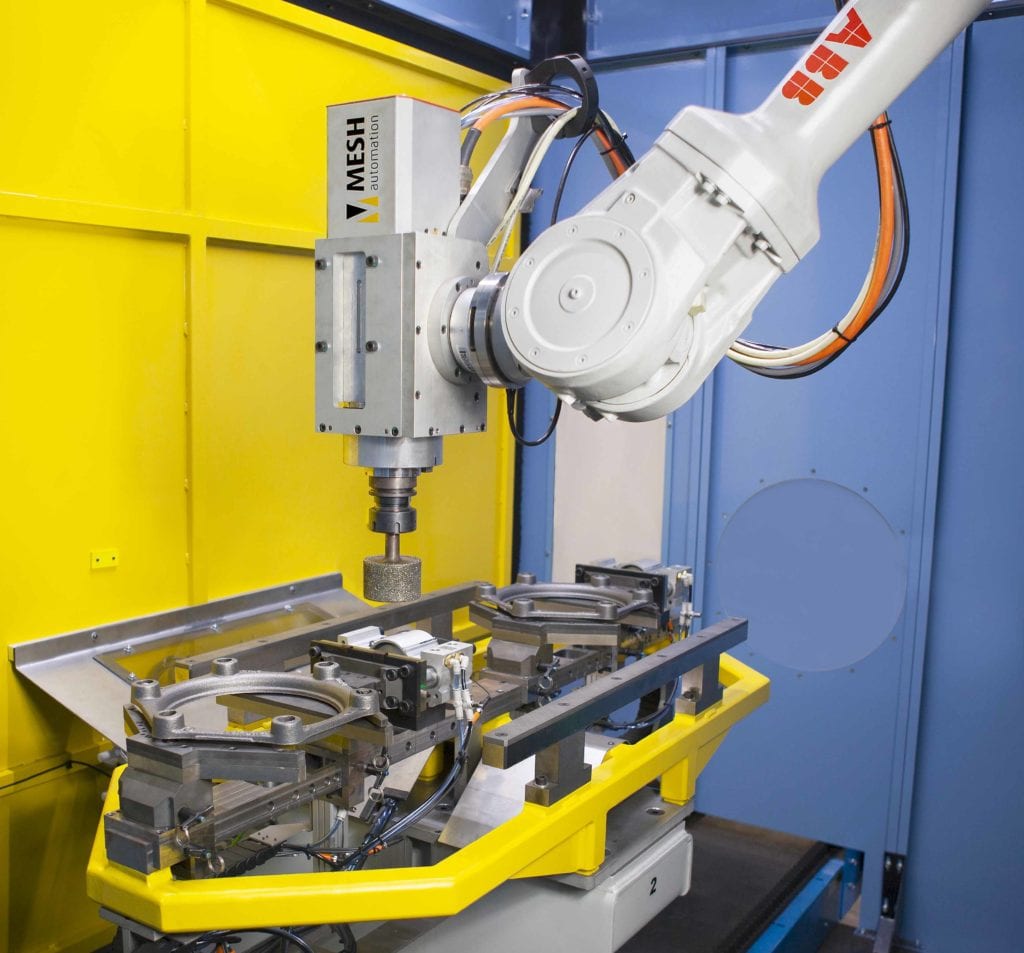

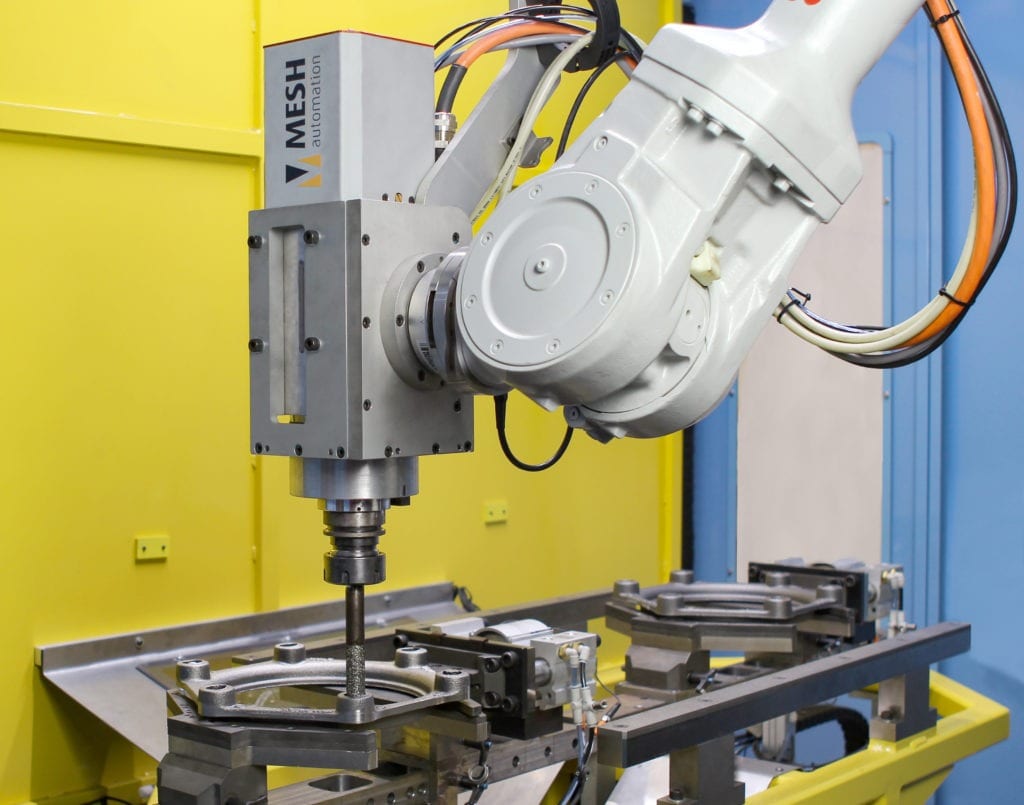

- Compliant robot-mounted tools

- Tool trees with several powered tools to be used in sequence

- Chip collections systems

MESH has also standardized on a dynamic HMI interface that allows the operator or process engineer to easily adjust the pressure, rate of transfer and other process parameters to adjust for changing conditions.

The MESH Experience

Our robotic grinding and finishing jobs have included:

- Grinding the weld beads and formed edges of welded cases and boxes to create a smooth, blended surface finish.

- Grinding of cast iron water fittings.

- Deburring, drilling and grinding aluminum power steering cylinders and undertaking vision quality checks.

- Deburring of steel pinion gears to the point of applying a chamfer to a beveled gear.

- Deburring pump impellers to remove all sharp edges and to remove high points.

- Deburring trailer hitches.

- Deburring, drilling and polishing rifle receivers.

- Polishing light reflectors as well as post forming and pre-anodizing.

- Machining PVC pipe flanges.

Additionally, we have completed numerous jobs that involved polishing aluminum and deflashing plastics.