MESH Press and Injection Mold Machine Tending

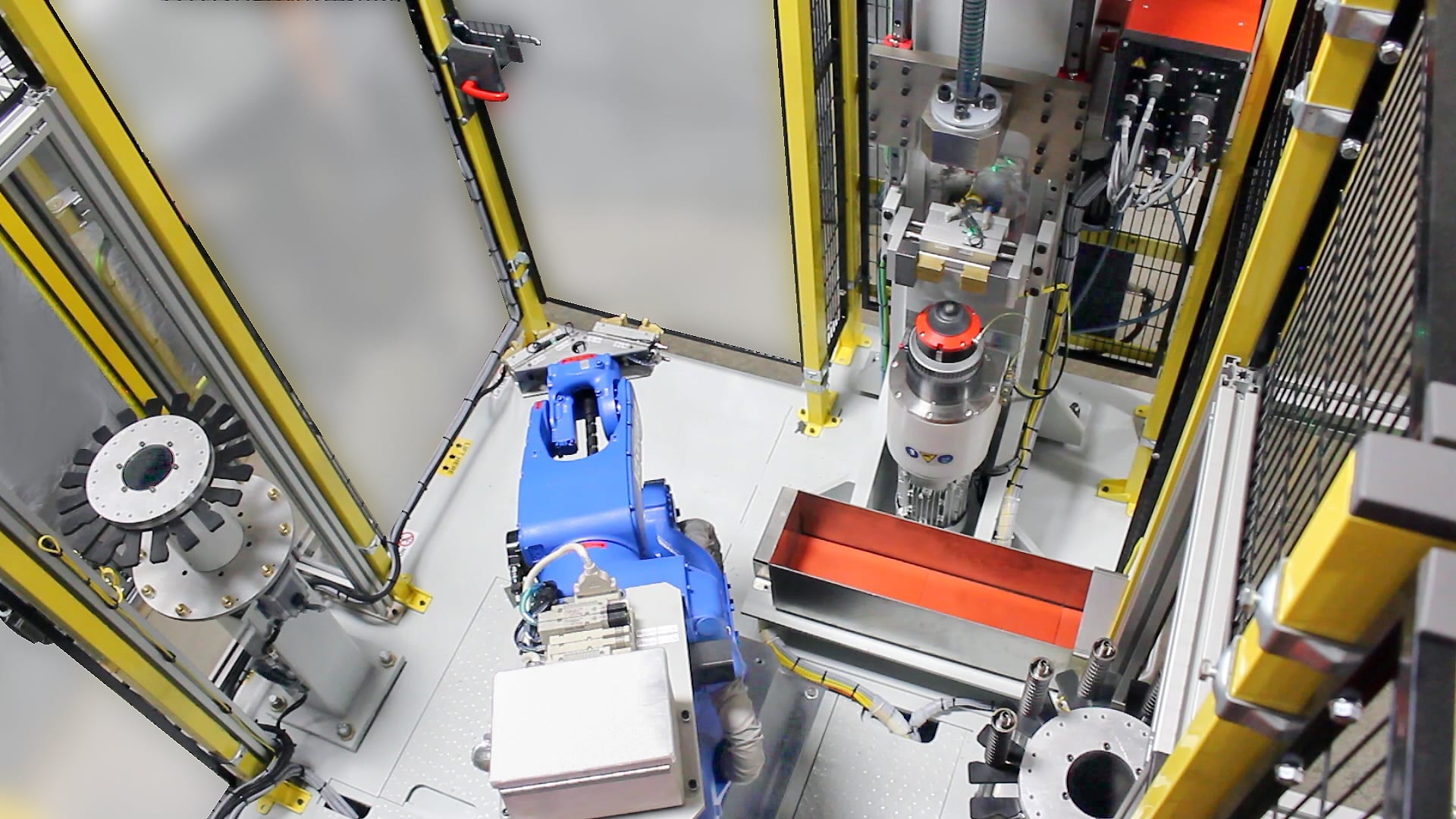

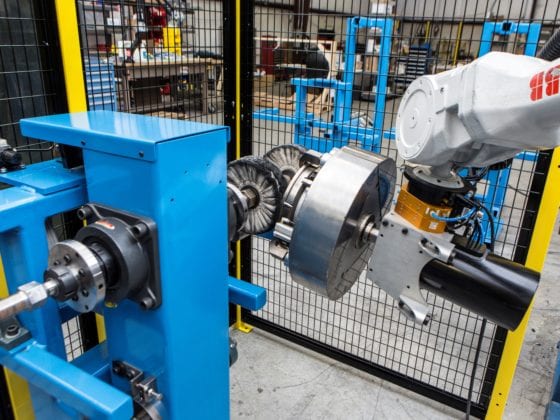

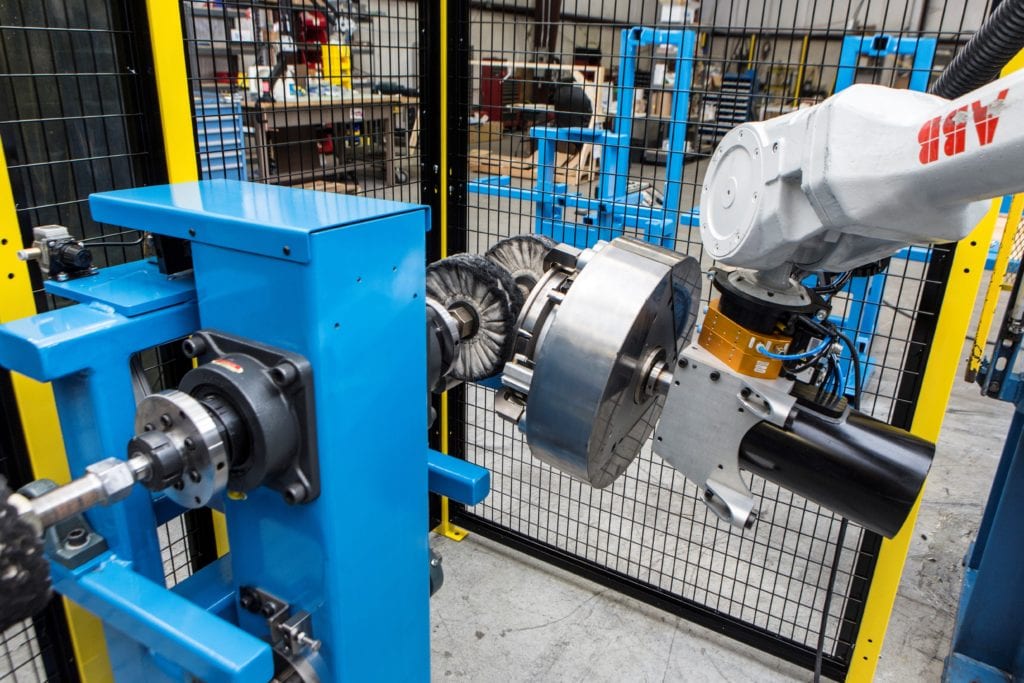

Press tending requires a special skill set and a complete understanding of how presses work. MESH has the experience and skills required to design the end of arm tools necessary to handle often oily and variable raw materials. We understand the nature of parts and how they behave through the pressing process.

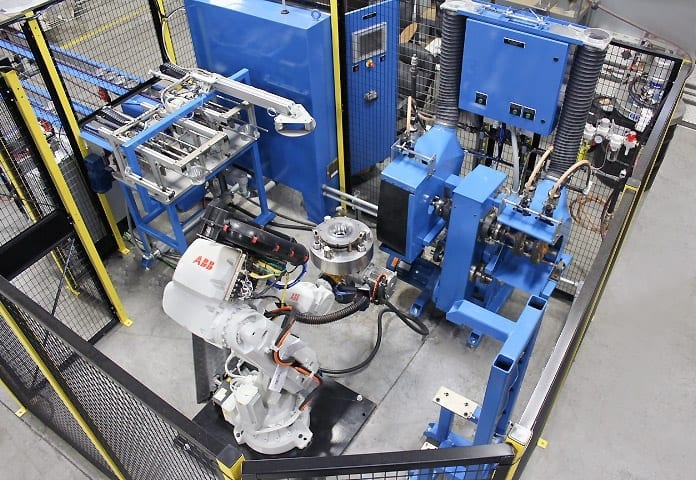

In addition, robot selection is critical in the proper analysis of the load, load inertia and speed required to make the desired cycle rates. MESH will do thorough calculations and real-life simulations before we select the robot and quote a cycle rate. On multiple press lines, simulations and ingenuity in a layout are necessary to meet the customer’s needs.

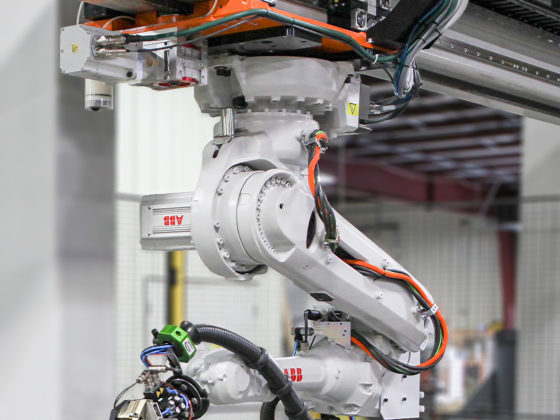

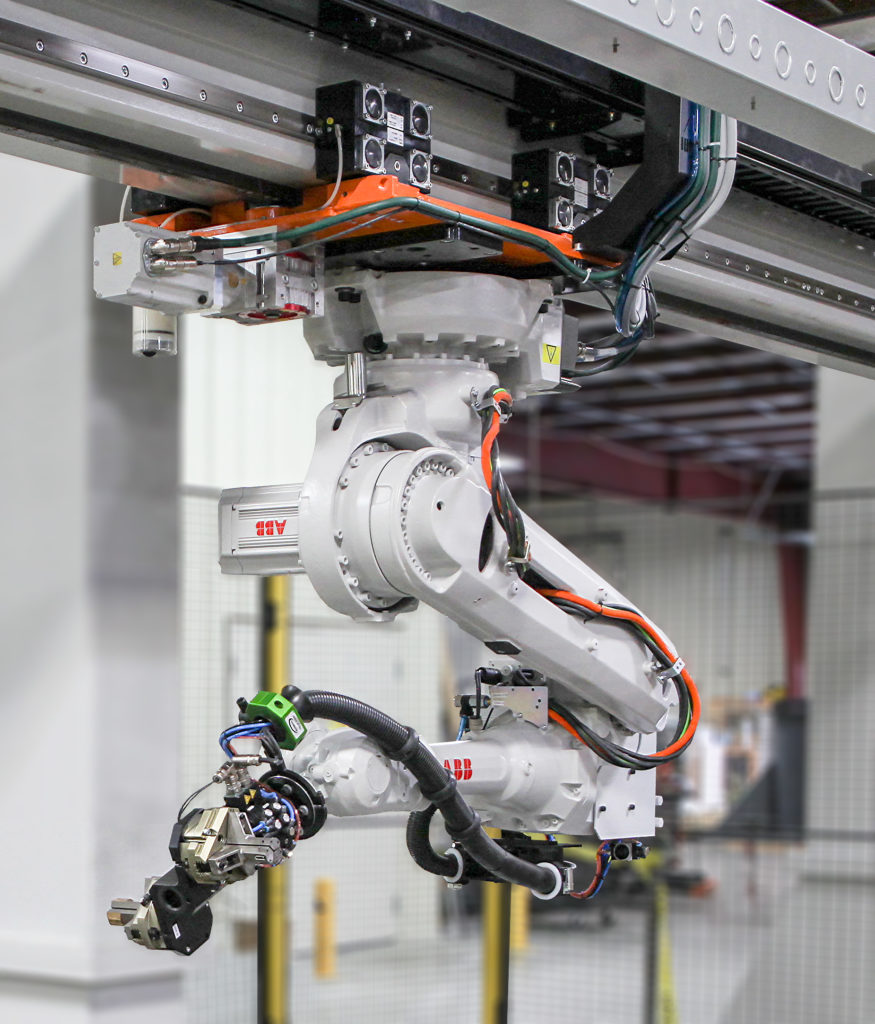

Injection Molding machine tending and after mold processing are areas where MESH has utilized all of their core competencies to develop the best solutions for our customers. We utilize our in-house robot transfer unit on applications that require long travel and our deflashing and deburring experience when needed.