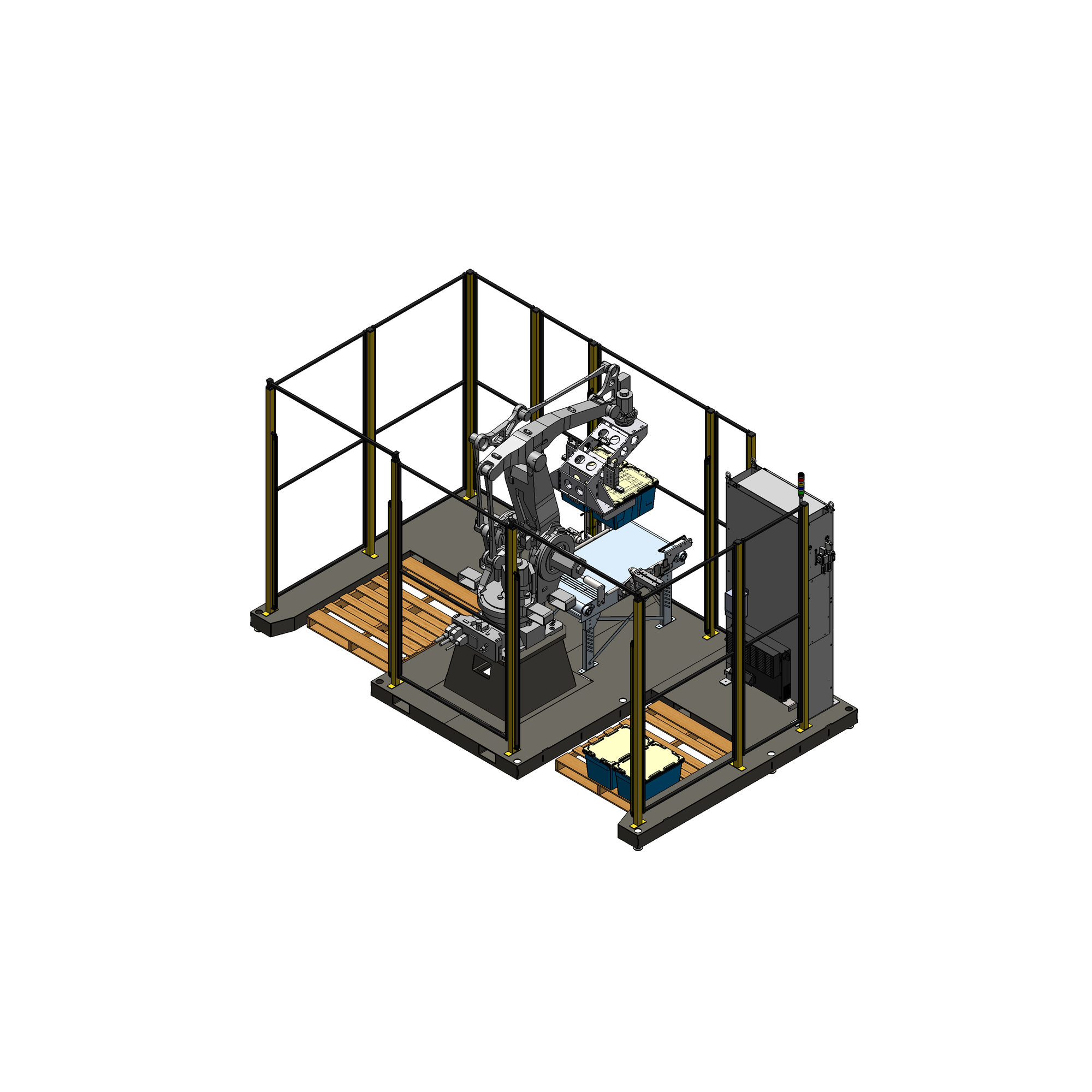

Product Description

Built around ABB’s IRB460 and IRB660 robots, this system brings fast, precise motion and compact design to high-duty tote palletizing. Backed by MESH’s 26 years of automation experience, it’s a refined, fully assembled solution that handles heavy, reusable plastic totes with consistent placement and stable stacking.

Our ABB Robotic Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard 15′ x 8.5′ metal skid)

- One infeed conveyor pick position (48”L x 18” roller face MDR)

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired, and pre-tested cell for rapid deployment

- Siemens PLC Control System

- 10″ Weintek Color Touchscreen HMI

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries handling rigid totes

- Scales easily across multiple sites, creating standardized performance

ABB Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the ABB-based MACPAL for Totes delivers predictable performance using a purpose-built mechanical gripping tool designed specifically for rigid totes.

- Application: Purpose-built robotic palletizer for heavy, reusable plastic totes

- Throughput: 5 to 6 cycles per minute (based on stack pattern and label orientation)

- Payload: Fork Style Gripper w/ Top Clamp; Dual-Pick, 30kg per tote payload

- Stack height: 80″ (Standard IRB460); 108″ (Optional Extended IRB660)

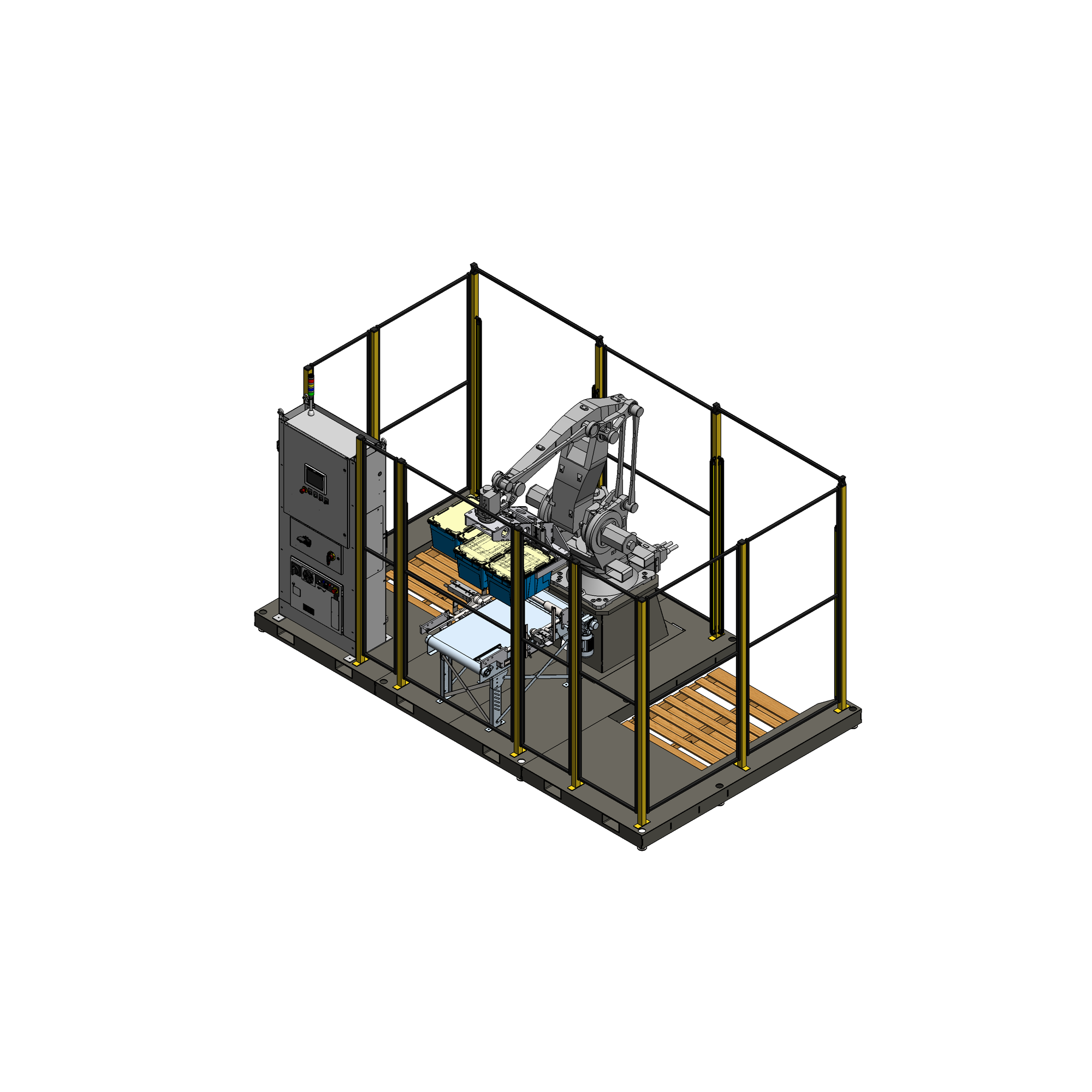

- Layout Options: Available in STANDARD (1 in/2 out) and COMPACT (1 in/1 out) configurations

- Control Options: Siemens (Standard) or Rockwell Compact GuardLogix (Optional)

- Designed for clean IT integration and cybersecurity alignment within modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

ABB Robotic Palletizer for Totes, Fully Assembled

Product Description

Built around ABB’s IRB460 and IRB660 robots, this system brings fast, precise motion and compact design to high-duty tote palletizing. Backed by MESH’s 26 years of automation experience, it’s a refined, fully assembled solution that handles heavy, reusable plastic totes with consistent placement and stable stacking.

Our ABB Robotic Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard 15′ x 8.5′ metal skid)

- One infeed conveyor pick position (48”L x 18” roller face MDR)

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired, and pre-tested cell for rapid deployment

- Siemens PLC Control System

- 10″ Weintek Color Touchscreen HMI

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries handling rigid totes

- Scales easily across multiple sites, creating standardized performance

ABB Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the ABB-based MACPAL for Totes delivers predictable performance using a purpose-built mechanical gripping tool designed specifically for rigid totes.

- Application: Purpose-built robotic palletizer for heavy, reusable plastic totes

- Throughput: 5 to 6 cycles per minute (based on stack pattern and label orientation)

- Payload: Fork Style Gripper w/ Top Clamp; Dual-Pick, 30kg per tote payload

- Stack height: 80″ (Standard IRB460); 108″ (Optional Extended IRB660)

- Layout Options: Available in STANDARD (1 in/2 out) and COMPACT (1 in/1 out) configurations

- Control Options: Siemens (Standard) or Rockwell Compact GuardLogix (Optional)

- Designed for clean IT integration and cybersecurity alignment within modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

Starting at