Product Description

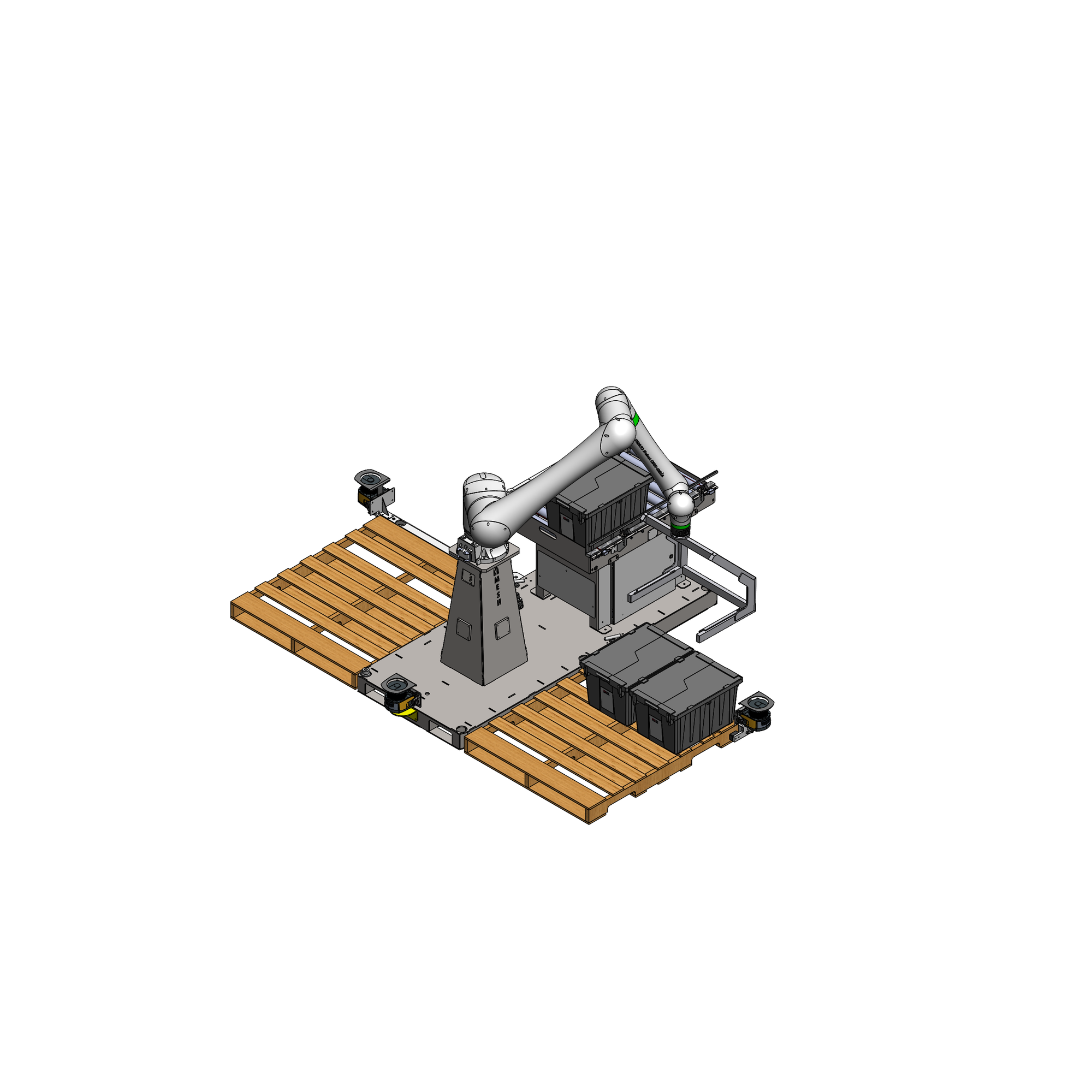

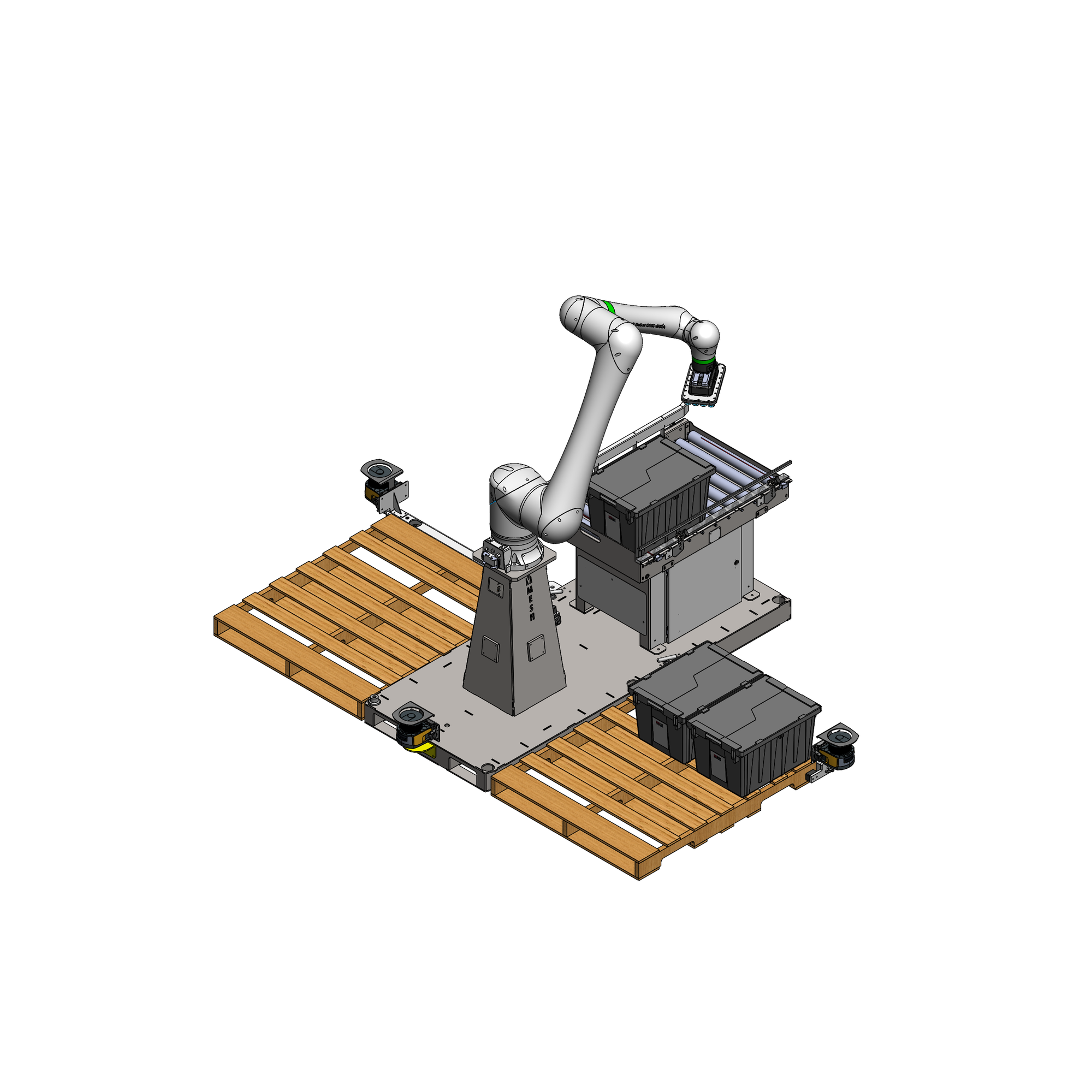

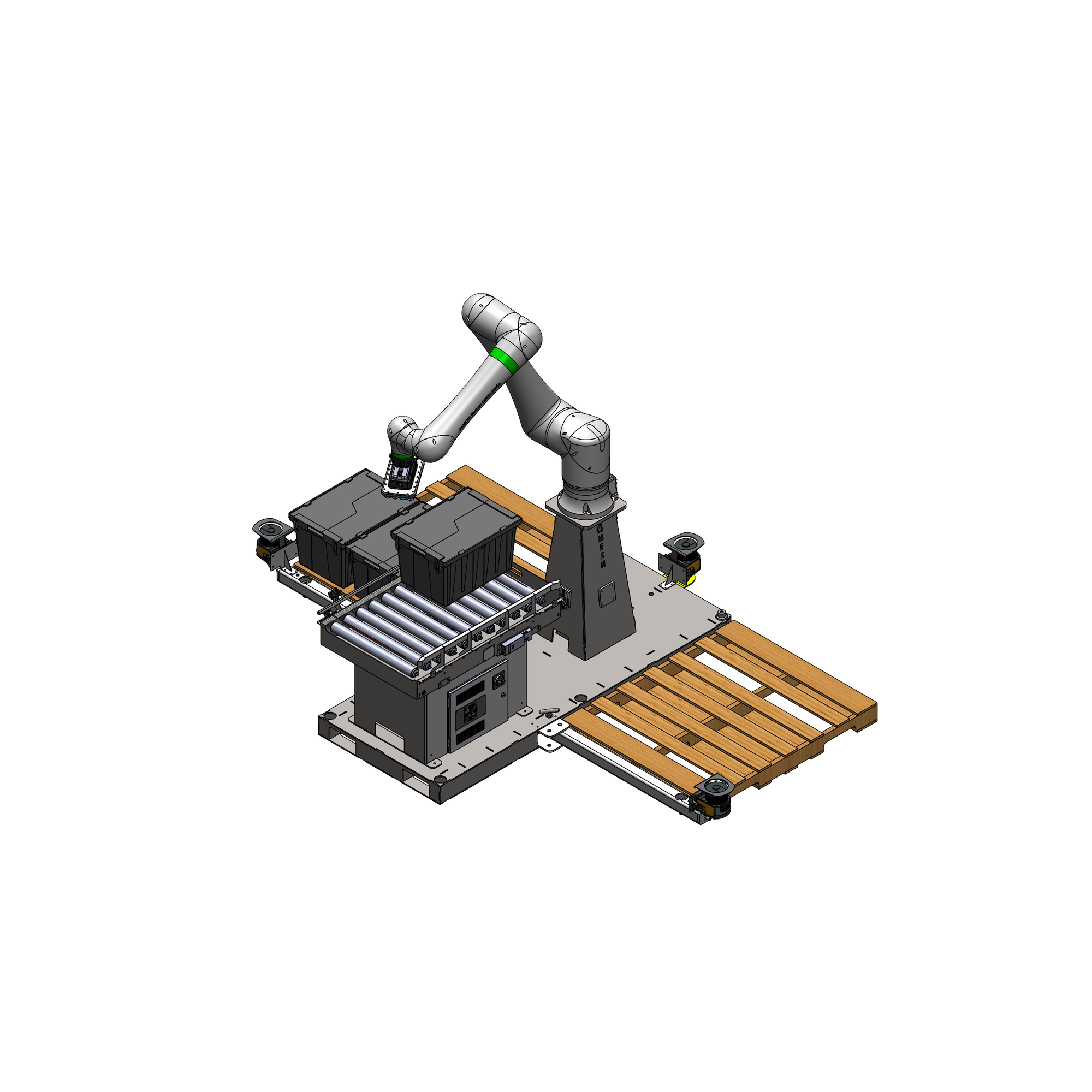

Our MACcoPAL FANUC Cobot Palletizer for Totes eliminates the strain and inefficiency of manual stacking. Powered by FANUC’s CRX-30iA cobot, it automates tote palletizing from a compact, skid-mounted platform that installs quickly and is typically up and running within a day. The result is steadier throughput, safer work, and flexibility to redeploy or scale as layouts change.

Stacking totes by hand ties up your operations team and increases the risk of repetitive strain injuries. Manual stacking also creates inconsistent output that’s difficult to plan around, especially when demand surges. Over time, it often becomes a bottleneck that slows growth and creates planning headaches.

Our FANUC Cobot Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on one tote size and stack pattern

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

Your Investment Outcome

By replacing a labor-intensive bottleneck with a flexible, low-maintenance system, you gain predictable output, safer work for your team, and a cost structure you can forecast with confidence.

FANUC Cobot Palletizing Solution Capabilities:

Built for fast deployment in warehousing and distribution, the FANUC-based MACcoPAL provides a reliable way to automate tote stacking without adding complexity to your floor.

- Turnkey collaborative palletizer for totes

- Throughput: Up to 5 cycles/minute

- Payload: 20kg single tote

- Stack Height: 72” standard, 96” with lift option

- Compact skid design, requires only 120V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification available

- Less than one day from installation to production

- Designed for fast deployment in warehousing, distribution, and fulfillment environments.

FANUC Cobot Palletizer for Totes, Turnkey

Product Description

Our MACcoPAL FANUC Cobot Palletizer for Totes eliminates the strain and inefficiency of manual stacking. Powered by FANUC’s CRX-30iA cobot, it automates tote palletizing from a compact, skid-mounted platform that installs quickly and is typically up and running within a day. The result is steadier throughput, safer work, and flexibility to redeploy or scale as layouts change.

Stacking totes by hand ties up your operations team and increases the risk of repetitive strain injuries. Manual stacking also creates inconsistent output that’s difficult to plan around, especially when demand surges. Over time, it often becomes a bottleneck that slows growth and creates planning headaches.

Our FANUC Cobot Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on one tote size and stack pattern

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

Your Investment Outcome

By replacing a labor-intensive bottleneck with a flexible, low-maintenance system, you gain predictable output, safer work for your team, and a cost structure you can forecast with confidence.

FANUC Cobot Palletizing Solution Capabilities:

Built for fast deployment in warehousing and distribution, the FANUC-based MACcoPAL provides a reliable way to automate tote stacking without adding complexity to your floor.

- Turnkey collaborative palletizer for totes

- Throughput: Up to 5 cycles/minute

- Payload: 20kg single tote

- Stack Height: 72” standard, 96” with lift option

- Compact skid design, requires only 120V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification available

- Less than one day from installation to production

- Designed for fast deployment in warehousing, distribution, and fulfillment environments.

Starting at