Product Description

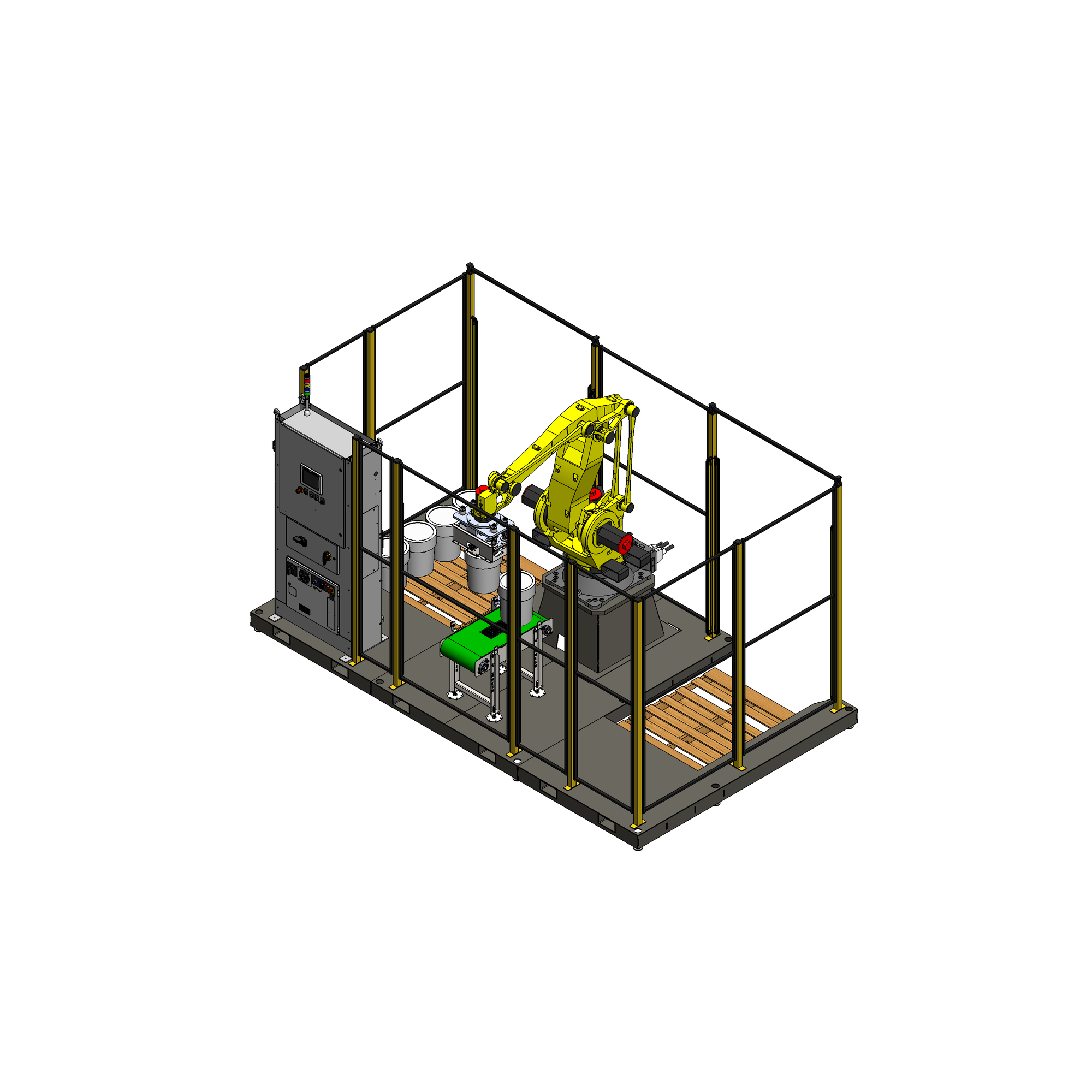

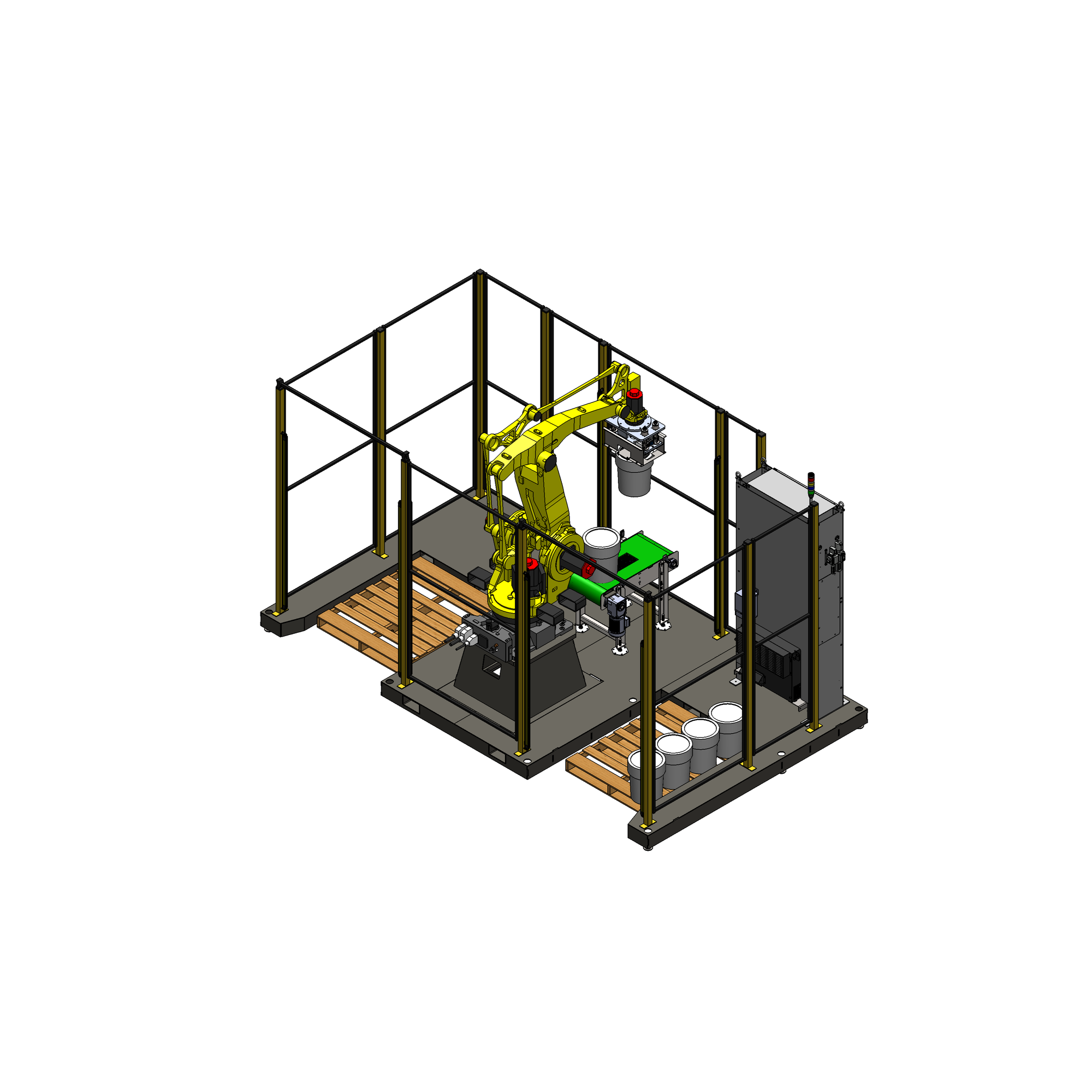

A turnkey and fully assembled palletizing solution built on the FANUC M-410iC robot family. Designed for round and cylindrical containers such as plastic pails, this system addresses unique challenges related to lid deformation, stack drift, and placement repeatability.

The system uses vacuum-based tooling designed for stable handling of pails across varying pallet patterns. Standardized layouts and controls provide a predictable and scalable solution for pail palletizing applications where reliability and repeatable performance are required.

Our FANUC Palletizer for Pails Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard Layout)

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired cell for rapid deployment (15’ x 8.5’ footprint)

- Integrated MACControl System: Fully integrated control stack with HMI-equipped control panel and interlocked power panel (480 VAC supply)

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries

- Scales easily across multiple sites, creating standardized performance

FANUC Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the FANUC-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for Pails and Buckets

- Throughput: 5 – 6 cycles/min (based on pallet pattern and pail stability)

- Payload: Vacuum Style, Single-Pick (30kg) or Dual-Pick (30kg per pail)

- Vacuum end-of-arm tooling engineered for cylindrical containers to maintain lid integrity

- Stack height: 80″ standard (M-410iC/110); 108″ with extended reach option (M-410iC/185)

- Available in COMPACT (10′ x 8.5′) and STANDARD (15′ x 8.5′) layouts

- Designed for clean IT connectivity and cybersecurity in modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Available Control Platforms: Siemens, Rockwell, or Omron

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

FANUC Robotic Palletizer for Pails, Fully Assembled

Product Description

A turnkey and fully assembled palletizing solution built on the FANUC M-410iC robot family. Designed for round and cylindrical containers such as plastic pails, this system addresses unique challenges related to lid deformation, stack drift, and placement repeatability.

The system uses vacuum-based tooling designed for stable handling of pails across varying pallet patterns. Standardized layouts and controls provide a predictable and scalable solution for pail palletizing applications where reliability and repeatable performance are required.

Our FANUC Palletizer for Pails Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard Layout)

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired cell for rapid deployment (15’ x 8.5’ footprint)

- Integrated MACControl System: Fully integrated control stack with HMI-equipped control panel and interlocked power panel (480 VAC supply)

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries

- Scales easily across multiple sites, creating standardized performance

FANUC Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the FANUC-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for Pails and Buckets

- Throughput: 5 – 6 cycles/min (based on pallet pattern and pail stability)

- Payload: Vacuum Style, Single-Pick (30kg) or Dual-Pick (30kg per pail)

- Vacuum end-of-arm tooling engineered for cylindrical containers to maintain lid integrity

- Stack height: 80″ standard (M-410iC/110); 108″ with extended reach option (M-410iC/185)

- Available in COMPACT (10′ x 8.5′) and STANDARD (15′ x 8.5′) layouts

- Designed for clean IT connectivity and cybersecurity in modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Available Control Platforms: Siemens, Rockwell, or Omron

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

Starting at