Product Description

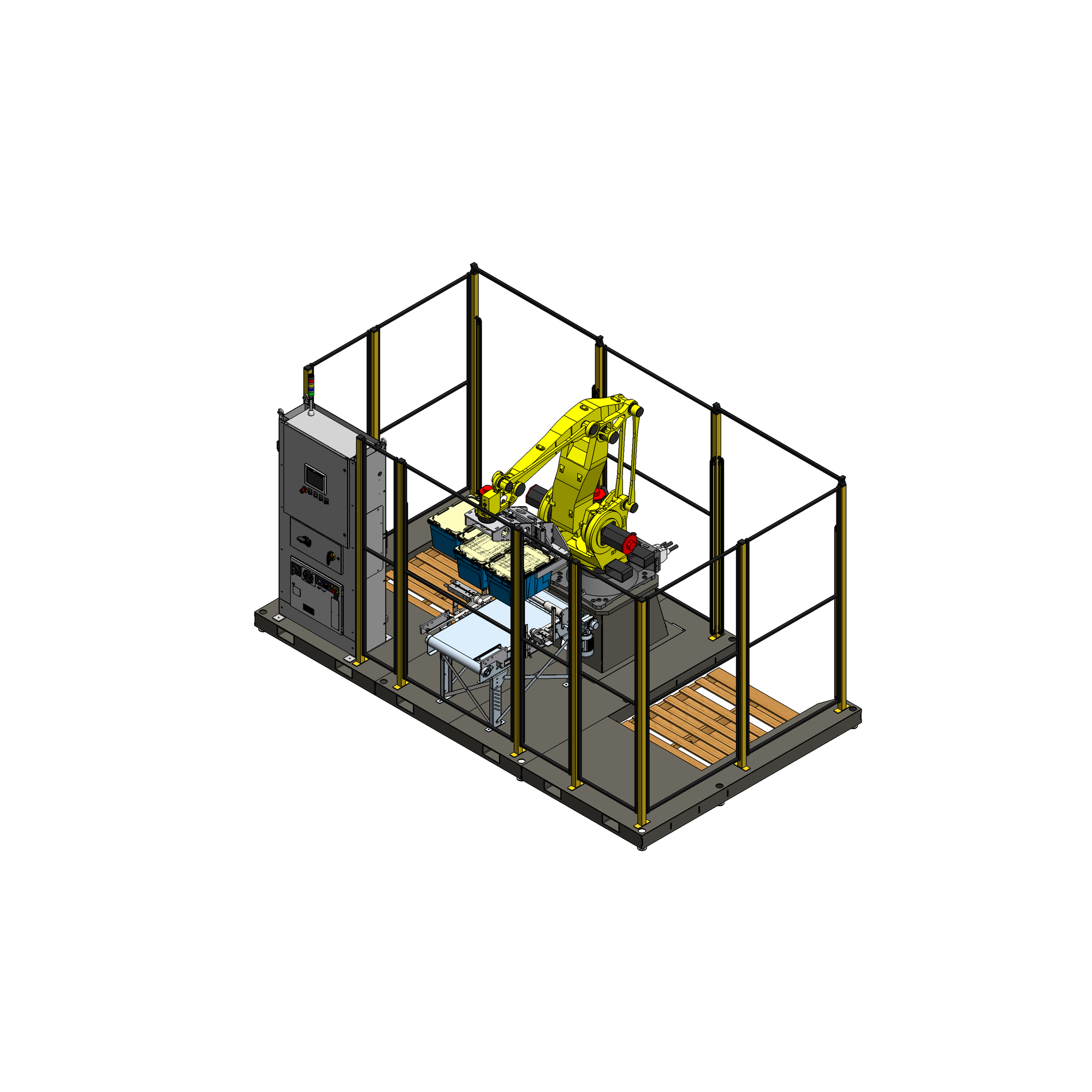

MESH’s FANUC palletizer for totes is a turnkey palletizing system built on the M-410iC and backed by 26 years of MESH Automation deployment experience. The FANUC Robotic Palletizer for Totes offers a low-risk path to robotic palletizing with predictable performance and clear ROI.

Our FANUC Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard Layout)

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired cell for rapid deployment (15’ x 8.5’ footprint)

- Integrated MACControl System: Fully integrated control stack with HMI-equipped control panel and interlocked power panel (480 VAC supply)

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries

- Scales easily across multiple sites, creating standardized performance

FANUC Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the FANUC-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for rigid plastic totes

- Throughput: 5 – 6 cycles/min (based on stack pattern and label orientation)

- Payload: Dual-pick mechanical gripper handling two 30 kg totes per cycle

- Fork Style end-of-arm tooling with top clamp proven across tote applications

- Stack height: 80″ standard; 108″ with extended reach option (M-410iC/185)

- Available in COMPACT (10′ x 8.5′) and STANDARD (15′ x 8.5′) layouts

- Designed for clean IT connectivity and cybersecurity in modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Pre-engineered, fully wired cell ships ready for installation in under a day

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

FANUC Robotic Palletizer for Totes, Fully Assembled

Product Description

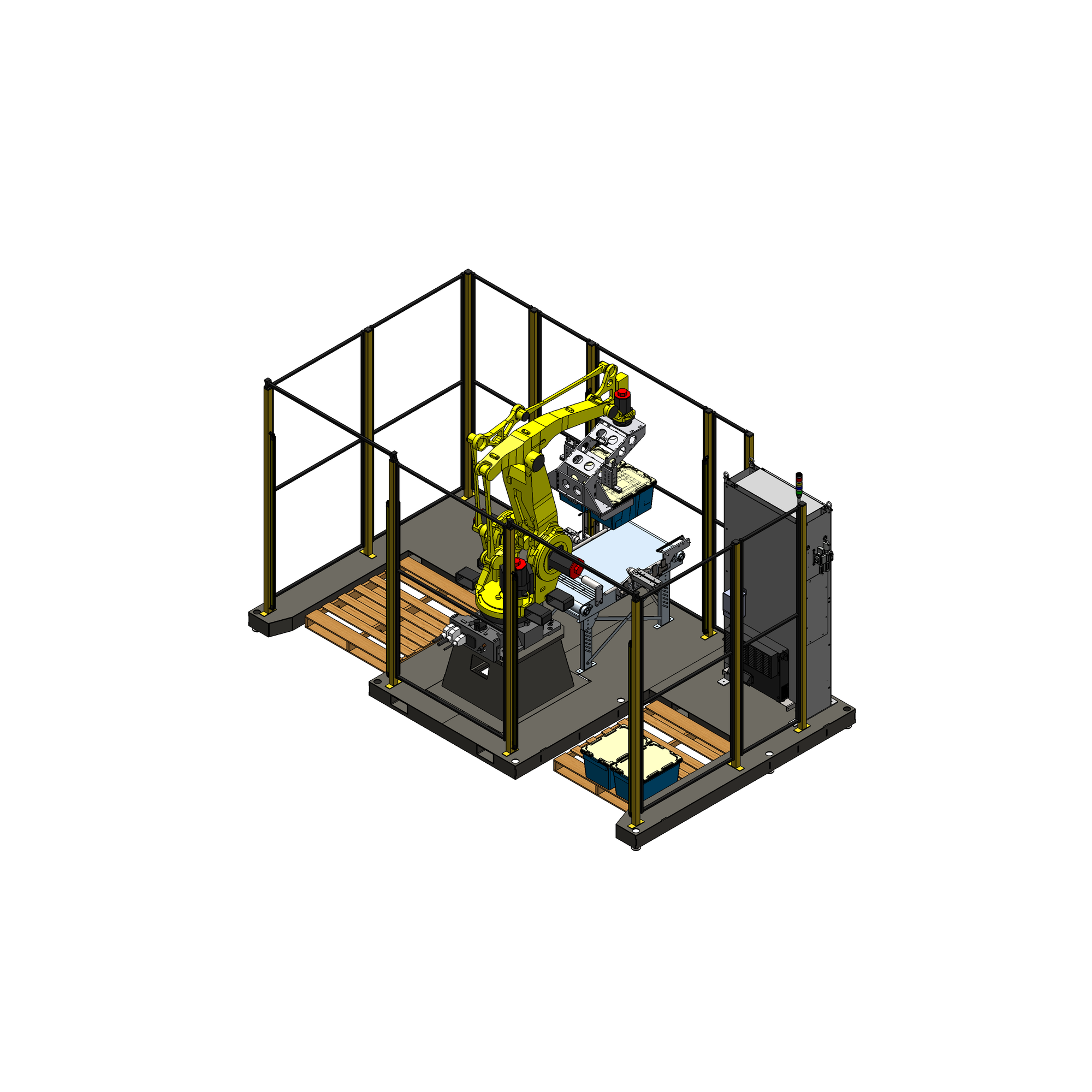

MESH’s FANUC palletizer for totes is a turnkey palletizing system built on the M-410iC and backed by 26 years of MESH Automation deployment experience. The FANUC Robotic Palletizer for Totes offers a low-risk path to robotic palletizing with predictable performance and clear ROI.

Our FANUC Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions (Standard Layout)

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre-wired cell for rapid deployment (15’ x 8.5’ footprint)

- Integrated MACControl System: Fully integrated control stack with HMI-equipped control panel and interlocked power panel (480 VAC supply)

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing industries

- Scales easily across multiple sites, creating standardized performance

FANUC Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the FANUC-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for rigid plastic totes

- Throughput: 5 – 6 cycles/min (based on stack pattern and label orientation)

- Payload: Dual-pick mechanical gripper handling two 30 kg totes per cycle

- Fork Style end-of-arm tooling with top clamp proven across tote applications

- Stack height: 80″ standard; 108″ with extended reach option (M-410iC/185)

- Available in COMPACT (10′ x 8.5′) and STANDARD (15′ x 8.5′) layouts

- Designed for clean IT connectivity and cybersecurity in modern plant networks

- NFPA 79 compliant controls; UL 508A certification available

- Pre-engineered, fully wired cell ships ready for installation in under a day

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

Starting at