Product Description

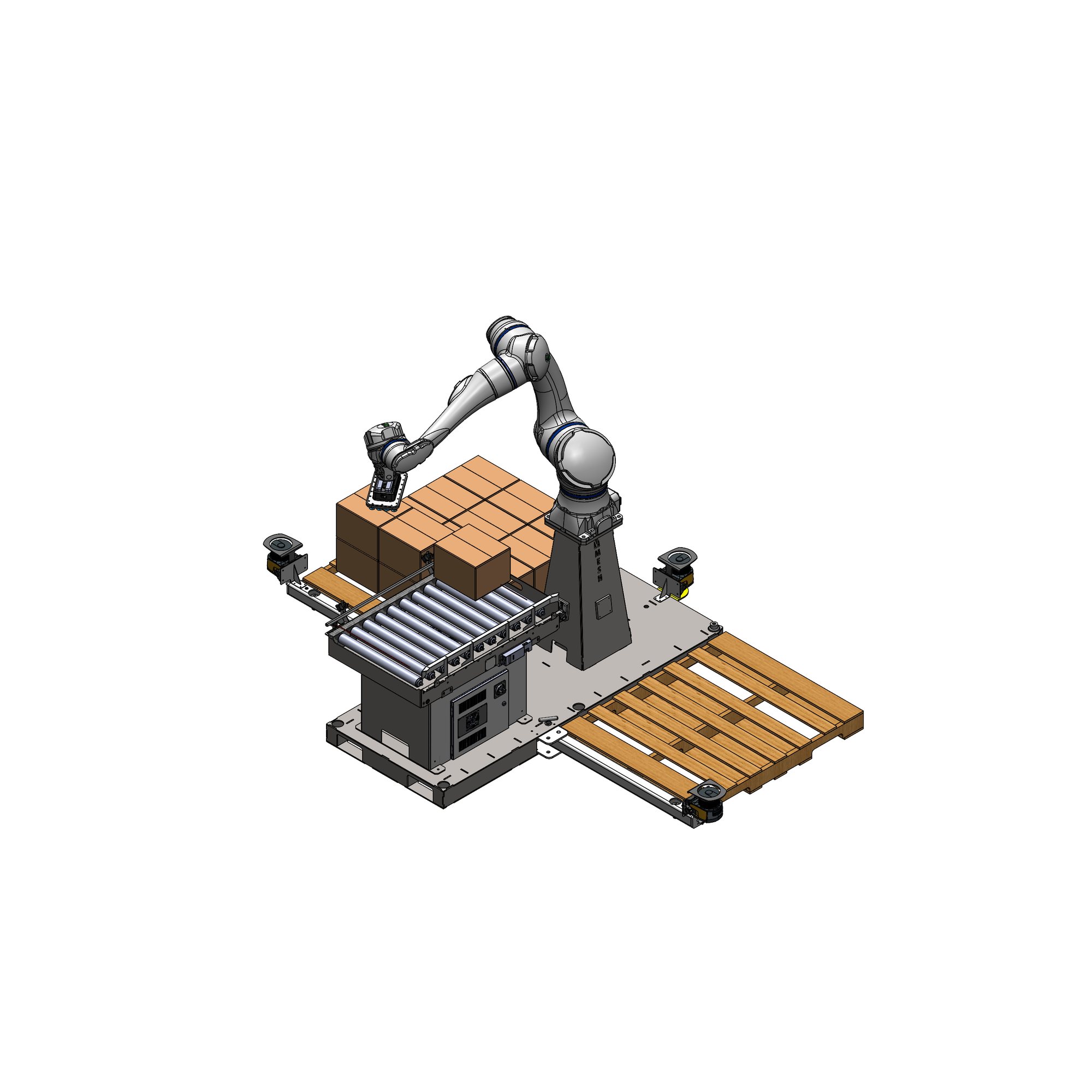

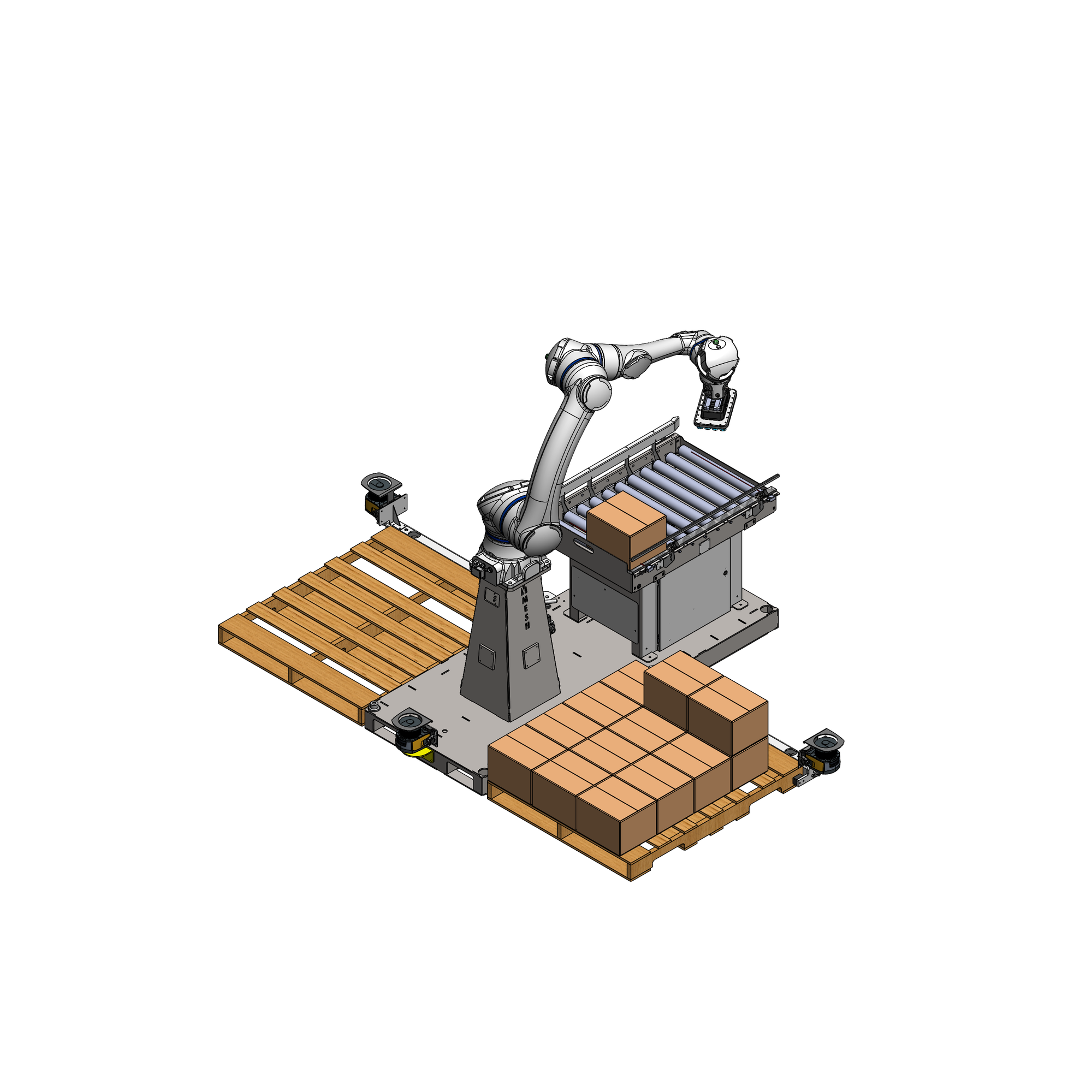

The MACcoPAL Yaskawa Cobot Palletizer for Boxes is a collaborative palletizing system designed for quick startup and flexible operation. Powered by Yaskawa’s 30 kg payload HC30PL cobot with 1.7 m reach, MACcoPAL provides a safe and reliable way to automate end-of-line palletizing without the need for a large, fixed installation. Each unit ships skid-mounted for rapid installation or redeployment, and three area scanners with optional light fencing define a safe working area. Yaskawa’s Power and Force Limiting (PFL) technology enables safe operation alongside people, while the scanners allow higher robot speeds when the zone is clear. Each system includes MESH’s NFPA 79-compliant controls platform, with optional UL 508A certification.

MESH’s PalletXBuilder software gives operators a straightforward, no-code software solution for creating and maintaining pallet patterns, enabling full ownership of the system without relying on robot programming expertise.

Our Yaskawa Cobot Palletizer for Boxes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on two box sizes

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

An Ideal Solution for Food and Beverage Palletizing

At the heart of this solution is Yaskawa’s HC30PL cobot, which comes standard with IP67 protection and NSF H1 certified food-grade grease. This makes MACcoPAL well suited for palletizing downstream of secondary packaging lines in the food and beverage industry.

The system handles vacuum-pickable formats such as closed-top cases, cartons, multipacks, and vacuum-sealed beverage trays under 20 kg. MACcoPAL has a proven track record with customers in snack foods, confectionery, and baked goods, where consistent throughput and reduced ergonomic strain are critical to production.

Yaskawa Cobot Palletizing Solution Capabilities:

- Turnkey collaborative palletizer for boxes, cartons, and cases

- Throughput: Up to 6 cycles/minute

- Payload: 20kg single-box mode, 12.5kg per box in dual-pick mode

- Stack Height: 72” standard, >90” with lift option

- Compact skid design, requires only 120V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification available

- Food-grade design: IP67 protection and NSF H1 certified food-grade grease

Yaskawa Cobot Palletizer for Boxes, Turnkey

Product Description

The MACcoPAL Yaskawa Cobot Palletizer for Boxes is a collaborative palletizing system designed for quick startup and flexible operation. Powered by Yaskawa’s 30 kg payload HC30PL cobot with 1.7 m reach, MACcoPAL provides a safe and reliable way to automate end-of-line palletizing without the need for a large, fixed installation. Each unit ships skid-mounted for rapid installation or redeployment, and three area scanners with optional light fencing define a safe working area. Yaskawa’s Power and Force Limiting (PFL) technology enables safe operation alongside people, while the scanners allow higher robot speeds when the zone is clear. Each system includes MESH’s NFPA 79-compliant controls platform, with optional UL 508A certification.

MESH’s PalletXBuilder software gives operators a straightforward, no-code software solution for creating and maintaining pallet patterns, enabling full ownership of the system without relying on robot programming expertise.

Our Yaskawa Cobot Palletizer for Boxes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on two box sizes

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

An Ideal Solution for Food and Beverage Palletizing

At the heart of this solution is Yaskawa’s HC30PL cobot, which comes standard with IP67 protection and NSF H1 certified food-grade grease. This makes MACcoPAL well suited for palletizing downstream of secondary packaging lines in the food and beverage industry.

The system handles vacuum-pickable formats such as closed-top cases, cartons, multipacks, and vacuum-sealed beverage trays under 20 kg. MACcoPAL has a proven track record with customers in snack foods, confectionery, and baked goods, where consistent throughput and reduced ergonomic strain are critical to production.

Yaskawa Cobot Palletizing Solution Capabilities:

- Turnkey collaborative palletizer for boxes, cartons, and cases

- Throughput: Up to 6 cycles/minute

- Payload: 20kg single-box mode, 12.5kg per box in dual-pick mode

- Stack Height: 72” standard, >90” with lift option

- Compact skid design, requires only 120V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification available

- Food-grade design: IP67 protection and NSF H1 certified food-grade grease

Starting at