Product Description

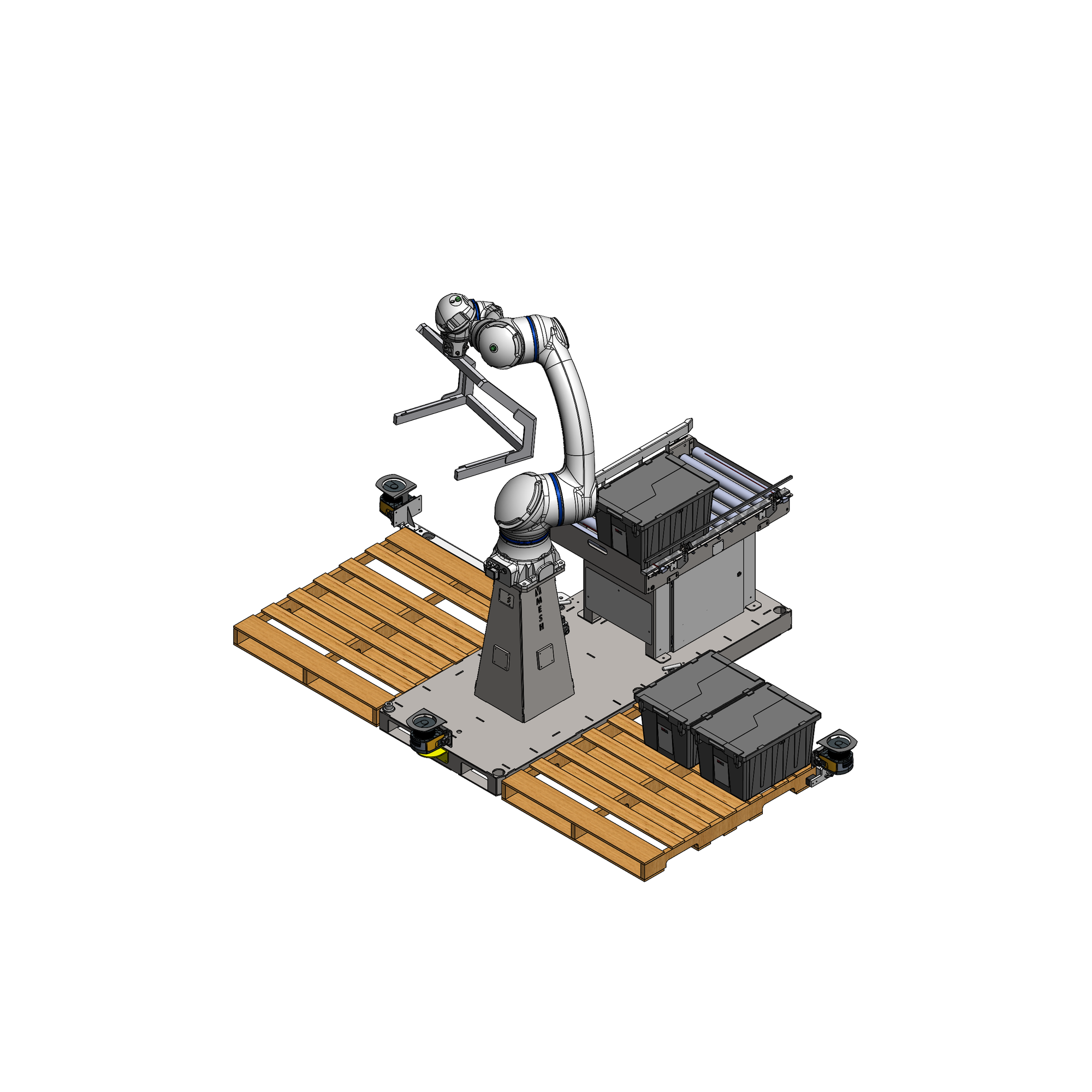

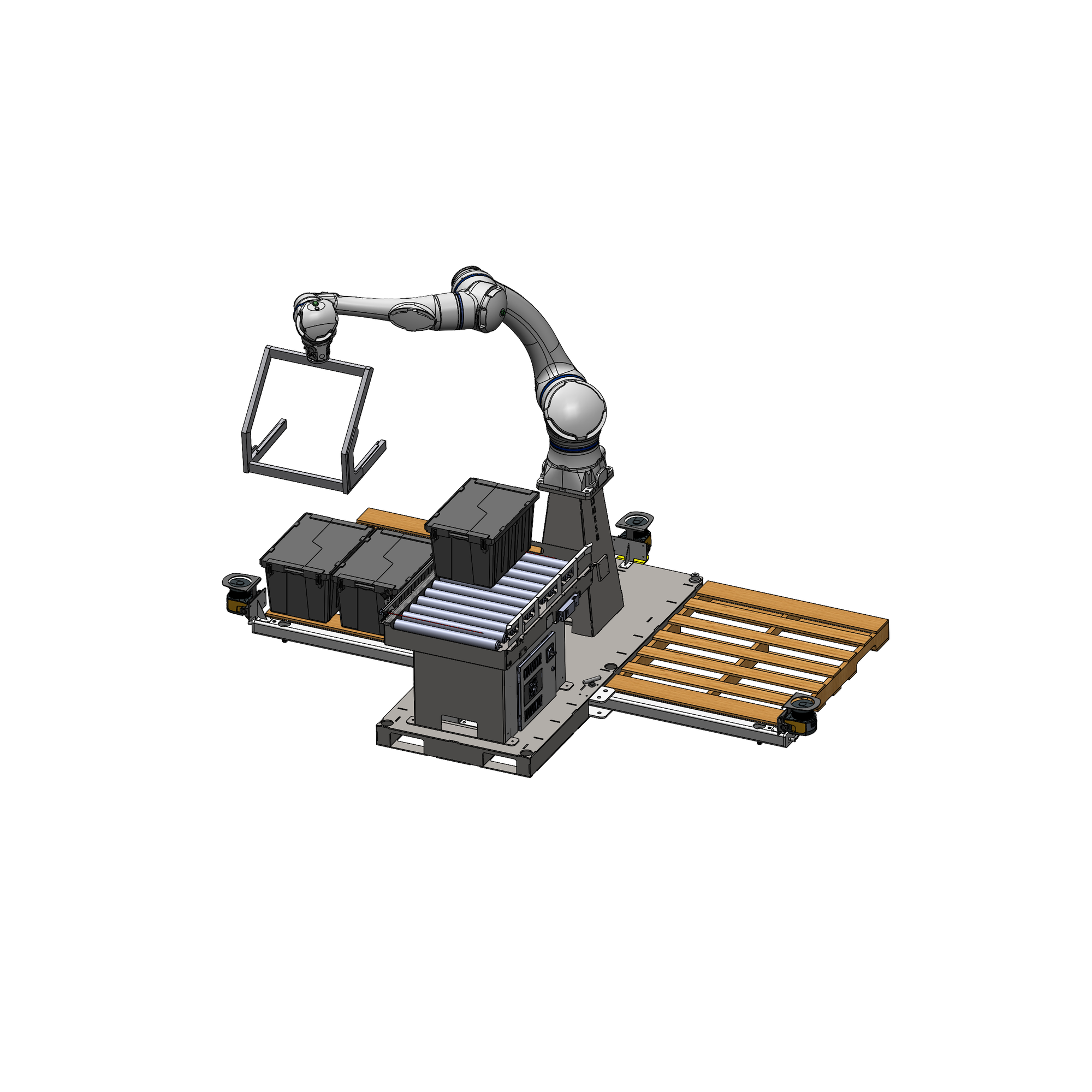

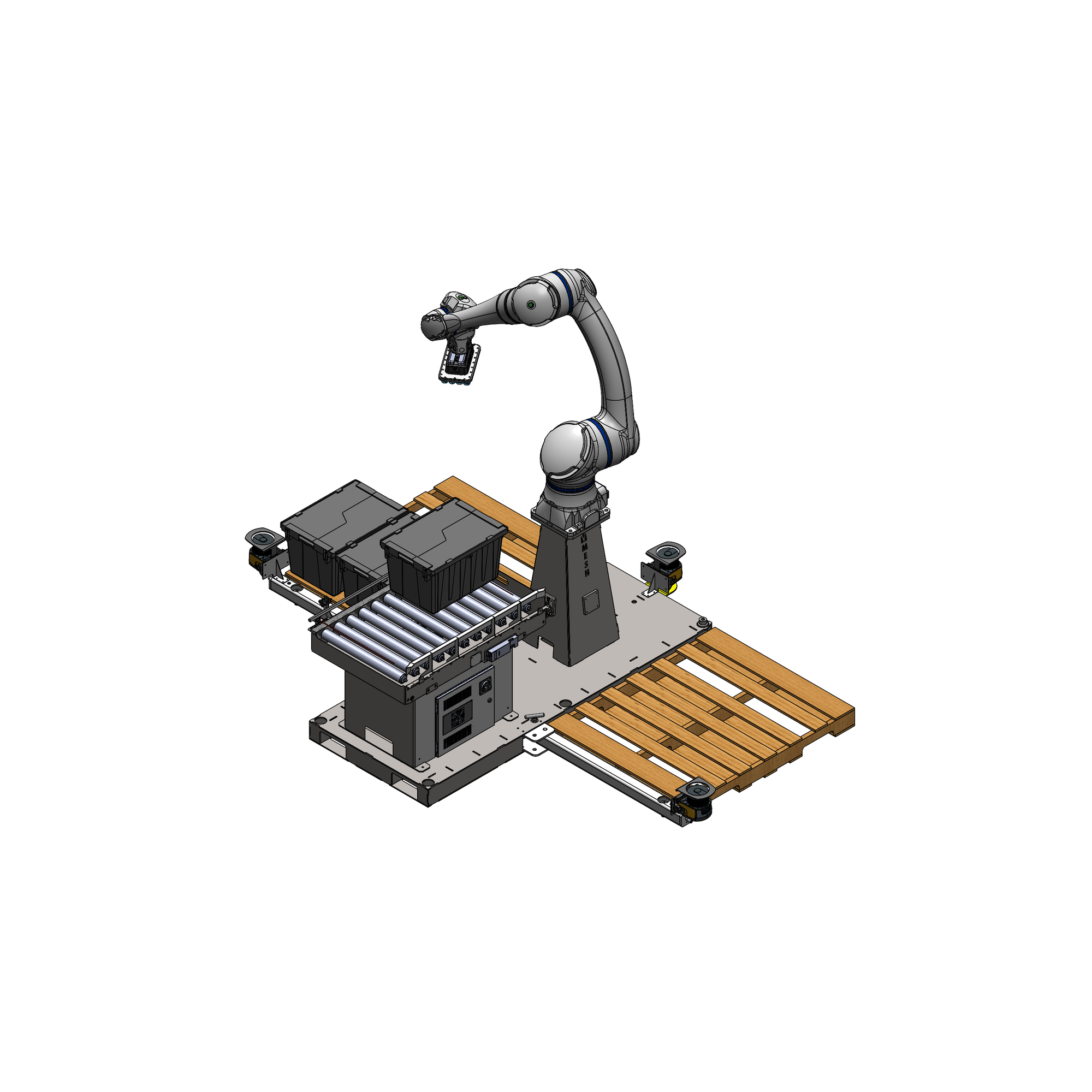

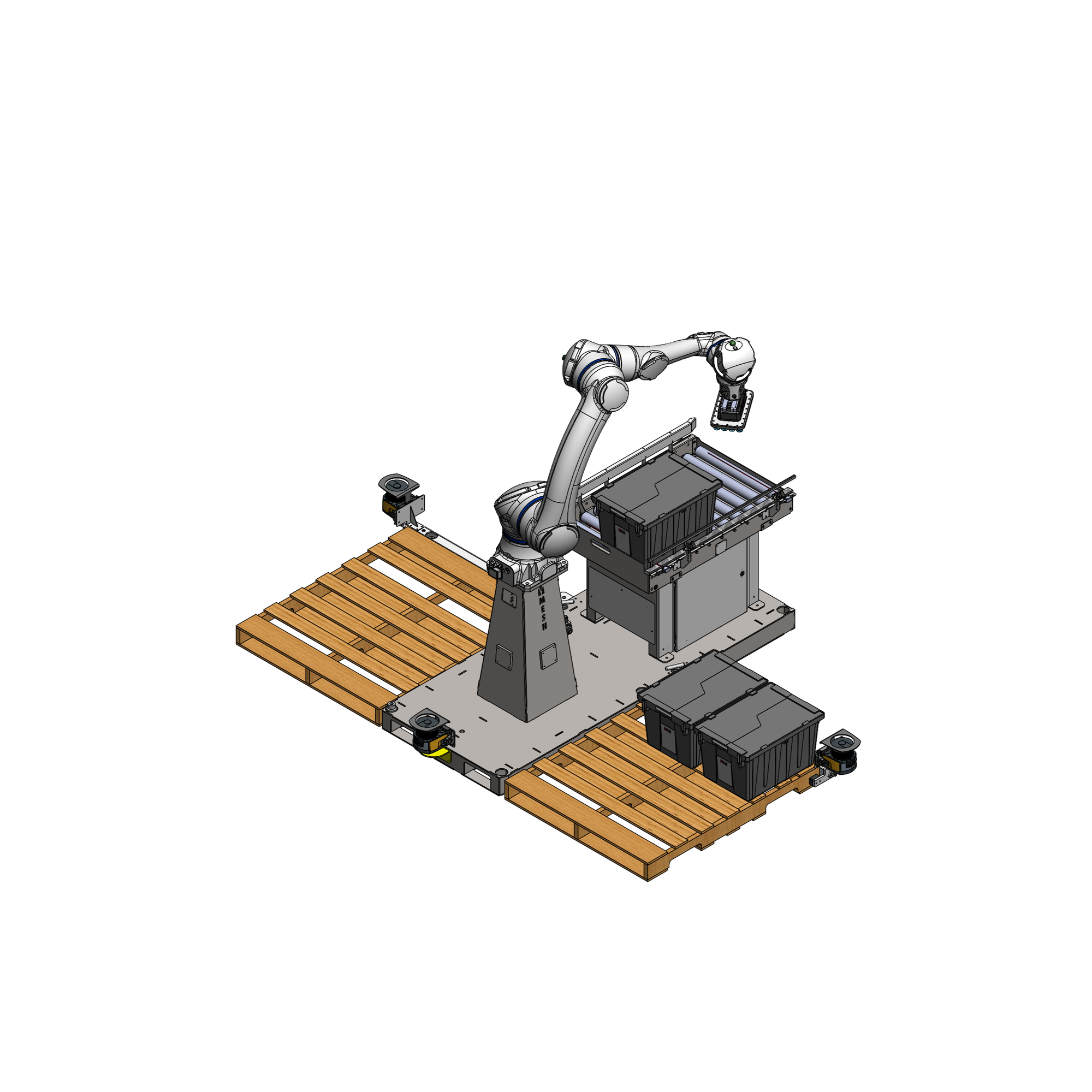

The MACcoPAL Yaskawa Cobot Palletizer for Totes helps companies stabilize their workforce and protect throughput by taking one of the hardest warehouse jobs to staff and automating it. With Yaskawa’s HC30PL cobot (30 kg payload, 1.7 m reach), tote palletizing becomes consistent, predictable, and safe. Most systems are running within a day of arrival.

Operators control pallet patterns through MESH’s PalletXBuilder software, keeping configuration in-house without programming expertise. Safety scanners monitor the zone, allowing fast cycles when the area is clear and safe interaction when people are present.

Our Yaskawa Cobot Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on two box sizes

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

Why Companies Choose MACcoPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing, pharma, and other tote-based industries

- Scales easily across multiple sites, creating standardized performance

YASKAWA Cobot Palletizing Solution Capabilities:

Engineered to meet the needs of pharmaceutical fulfillment and high-volume warehouse operations, the Yaskawa-based MACcoPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Turnkey collaborative palletizer for totes

- Throughput: Up to 5 cycles/minute

- Payload: 20 kg single tote

- Stack height: 72” standard, 96” with lift option

- Compact skid footprint, requires only 120 V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification optional

- Less than one day from installation to production

- Engineered for operations in distribution, warehousing, pharmaceutical fulfillment, and other tote-based operations.

Yaskawa Cobot Palletizer for Totes, Turnkey

Product Description

The MACcoPAL Yaskawa Cobot Palletizer for Totes helps companies stabilize their workforce and protect throughput by taking one of the hardest warehouse jobs to staff and automating it. With Yaskawa’s HC30PL cobot (30 kg payload, 1.7 m reach), tote palletizing becomes consistent, predictable, and safe. Most systems are running within a day of arrival.

Operators control pallet patterns through MESH’s PalletXBuilder software, keeping configuration in-house without programming expertise. Safety scanners monitor the zone, allowing fast cycles when the area is clear and safe interaction when people are present.

Our Yaskawa Cobot Palletizer for Totes Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48” x 40” max pallet size

- Fully tested at factory on two box sizes

- Shipped fully assembled and ready for operation

- Festo or SMC Compressed air prep and lockable air dump.

- Pedestal HMI stand with start, stop, reset and E-stop push buttons

- 120 Volt AC Control panel

- Comprehensive 1 year warranty

- PalletXBuilder software, MESH’s out of the box solution for GUI based pallet pattern generation. No programming expertise required.

Why Companies Choose MACcoPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing, pharma, and other tote-based industries

- Scales easily across multiple sites, creating standardized performance

YASKAWA Cobot Palletizing Solution Capabilities:

Engineered to meet the needs of pharmaceutical fulfillment and high-volume warehouse operations, the Yaskawa-based MACcoPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Turnkey collaborative palletizer for totes

- Throughput: Up to 5 cycles/minute

- Payload: 20 kg single tote

- Stack height: 72” standard, 96” with lift option

- Compact skid footprint, requires only 120 V AC power and compressed air

- NFPA 79-compliant controls platform, UL 508A certification optional

- Less than one day from installation to production

- Engineered for operations in distribution, warehousing, pharmaceutical fulfillment, and other tote-based operations.

Starting at