Product Description

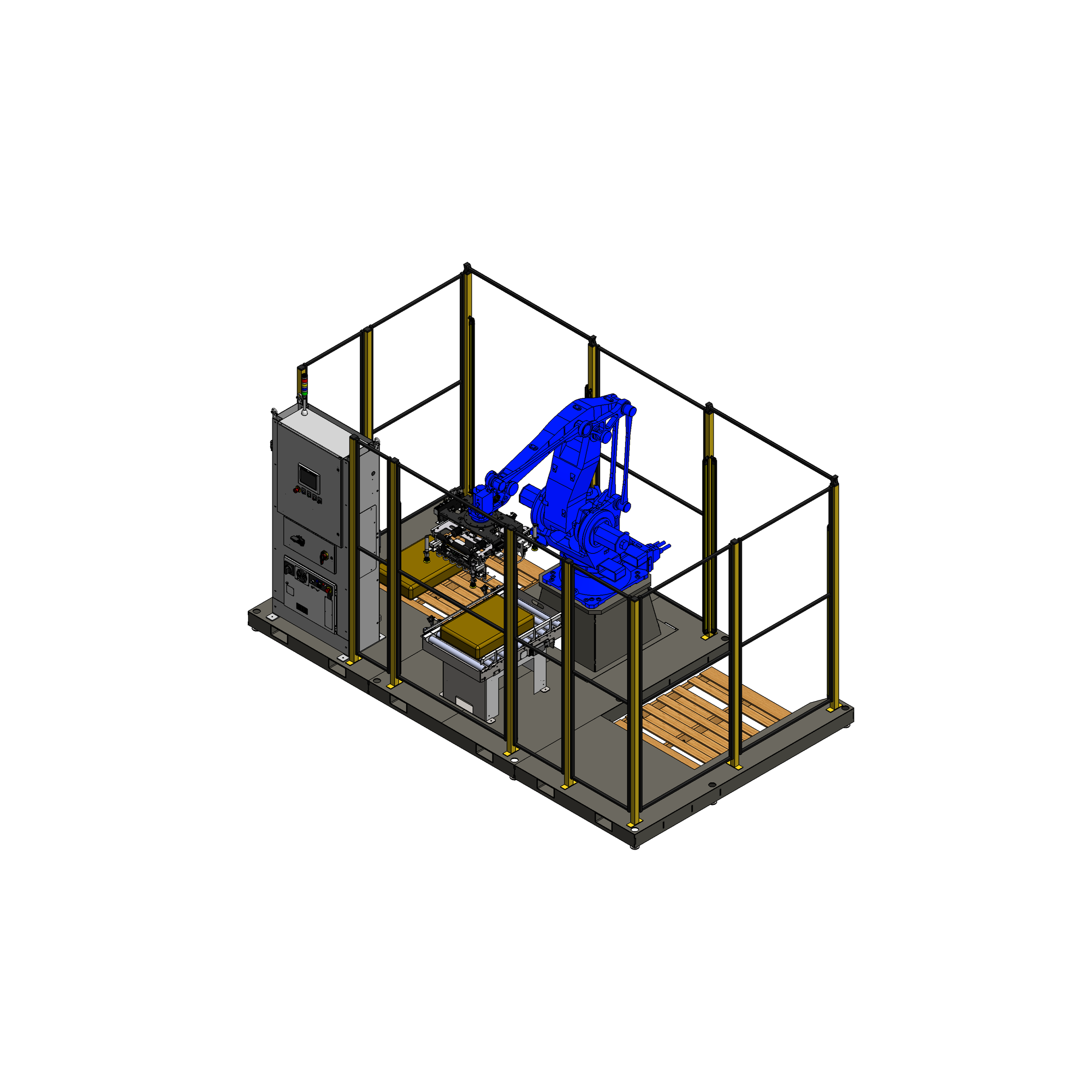

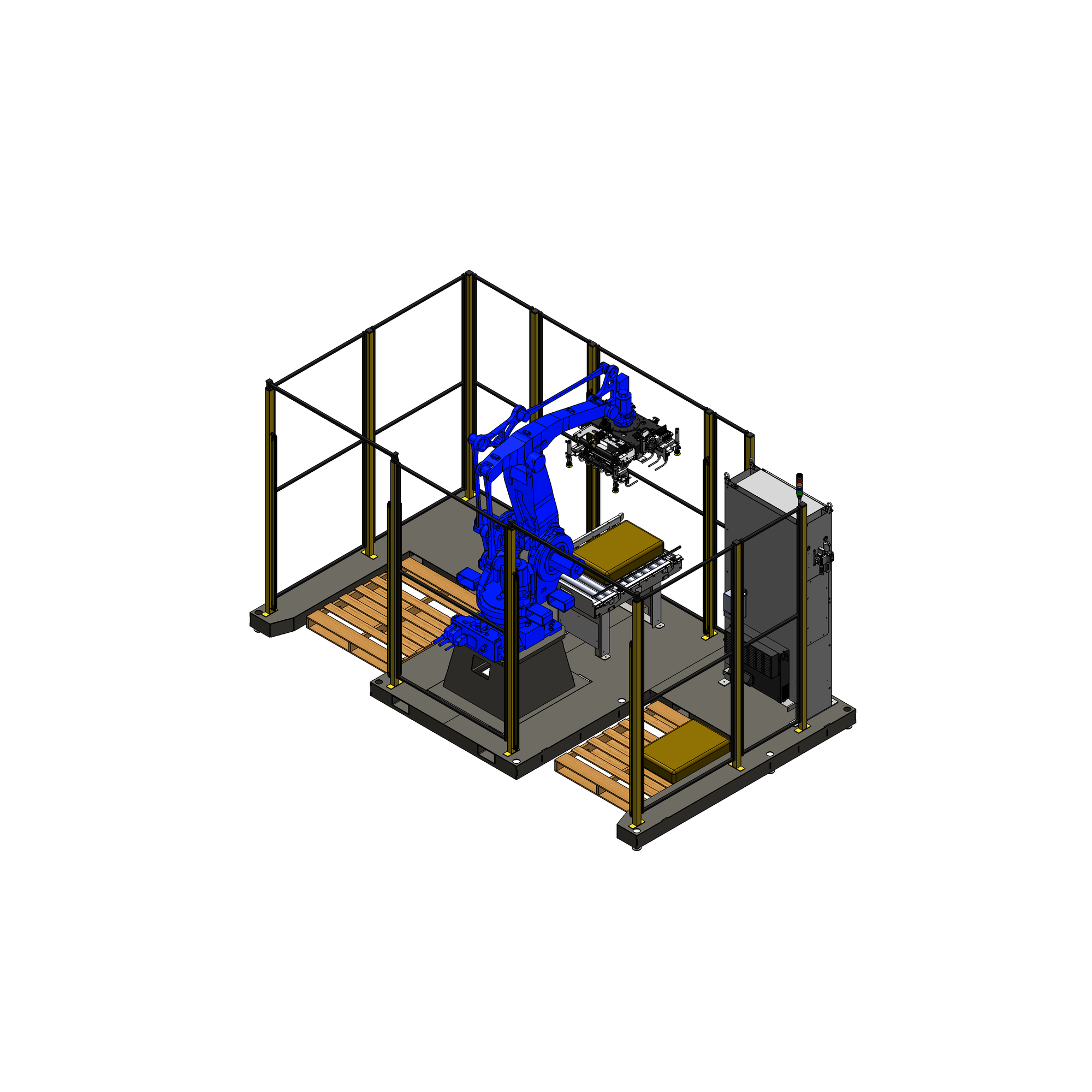

Take the strain and inconsistency out of manual bag stacking with a turnkey robotic palletizing system from MESH Automation. It pairs Yaskawa’s proven PL-series robot with bag-specific tooling to deliver consistent, repeatable pallet loads shift after shift.

Choose from two gripper families to match your application: a claw-style head for highest throughput and forgiving handling of partial-fill or sagging bags, and a vacuum head for a more cost-effective option at lower rates. MESH engineers will confirm compatibility with your product and may recommend additional bag-conditioning automation to achieve best performance.

Every MACPal solution is delivered as a skid-mounted, pre-wired cell for rapid installation. Standard models support two pallet stations, while a compact configuration is available for limited-space operations. Each control platform is built to NFPA 79 standards and can be UL 508A-certified upon request. IT and cybersecurity readiness are built into every system, enabling seamless integration into connected plant networks.

Our YASKAWA Palletizer for Bags Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre wired cell for rapid deployment

- Festo or SMC compressed air prep and lockable air dump

- Pedestal HMI stand with start, stop, reset and E stop push buttons

- 120 volt AC control panel

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing-based industries

- Scales easily across multiple sites, creating standardized performance

YASKAWA Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the Yaskawa-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for bags, sacks, and flexible packaging found in feed, seed, fertilizer, chemical, aggregate, soil, mulch, stone, gravel, and pet food operations

- Throughput: up to 22 bags/min (application dependent)

- Payload: 1×25 kg per cycle; optional dual-pick 2×25 kg

- Stack height: 75″ standard; 108″ with extended reach option

- Available in COMPACT and STANDARD layouts

- NFPA 79 compliant controls; UL 508A certification available

- Pre-engineered, fully wired cell ships ready for installation in under a day

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

Yaskawa Robotic Palletizer for Bags, Fully Assembled

Product Description

Take the strain and inconsistency out of manual bag stacking with a turnkey robotic palletizing system from MESH Automation. It pairs Yaskawa’s proven PL-series robot with bag-specific tooling to deliver consistent, repeatable pallet loads shift after shift.

Choose from two gripper families to match your application: a claw-style head for highest throughput and forgiving handling of partial-fill or sagging bags, and a vacuum head for a more cost-effective option at lower rates. MESH engineers will confirm compatibility with your product and may recommend additional bag-conditioning automation to achieve best performance.

Every MACPal solution is delivered as a skid-mounted, pre-wired cell for rapid installation. Standard models support two pallet stations, while a compact configuration is available for limited-space operations. Each control platform is built to NFPA 79 standards and can be UL 508A-certified upon request. IT and cybersecurity readiness are built into every system, enabling seamless integration into connected plant networks.

Our YASKAWA Palletizer for Bags Comes with these Standard Options Included:

- Two outbound palletizing positions

- One infeed conveyor pick position

- 48 in x 40 in max pallet size

- Shipped as a skid mounted, pre wired cell for rapid deployment

- Festo or SMC compressed air prep and lockable air dump

- Pedestal HMI stand with start, stop, reset and E stop push buttons

- 120 volt AC control panel

- Comprehensive 1 year warranty

- PalletXBuilder pallet pattern software included

Why Companies Choose MACPAL

- Workforce stability through removal of a turnover-heavy task

- Predictable throughput across shifts and facilities

- Fixed cost structure compared to variable labor expense

- Faster ROI with installation-to-production in under a day

- Proven in warehousing-based industries

- Scales easily across multiple sites, creating standardized performance

YASKAWA Palletizing Robot Solution Capabilities:

Engineered to meet the needs of high-volume warehouse operations, the Yaskawa-based MACPAL delivers predictable performance with a footprint small enough to fit nearly anywhere.

- Purpose-built robotic palletizer for bags, sacks, and flexible packaging found in feed, seed, fertilizer, chemical, aggregate, soil, mulch, stone, gravel, and pet food operations

- Throughput: up to 22 bags/min (application dependent)

- Payload: 1×25 kg per cycle; optional dual-pick 2×25 kg

- Stack height: 75″ standard; 108″ with extended reach option

- Available in COMPACT and STANDARD layouts

- NFPA 79 compliant controls; UL 508A certification available

- Pre-engineered, fully wired cell ships ready for installation in under a day

- Safety Features Include: Risk assessment completed on base system & Light curtain protected palletizing positions

Starting at