Battery Plate 3D Vision Inspection Machine

Customer Requirements & Project Information

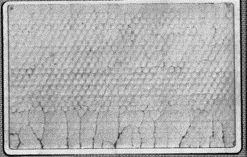

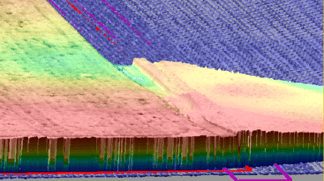

The customer required an automated machine that could inspect, stack, and quarantine out-of-spec battery plates. Inspection was primarily of the plate body looking for defects and holes in the plates.

The system was designed to take plates directly from the press and scan them as they were moving to the robot. If the plates were good, they were stacked into a bin to the desired quantity and the bad parts were dropped into a locked drawer.

The cycle rate was proven at 3 seconds per plate and the defects detected were as described below.

- Holes

- Gross Discoloration

- Verify Tab presence and hole location

- Weld seam quality

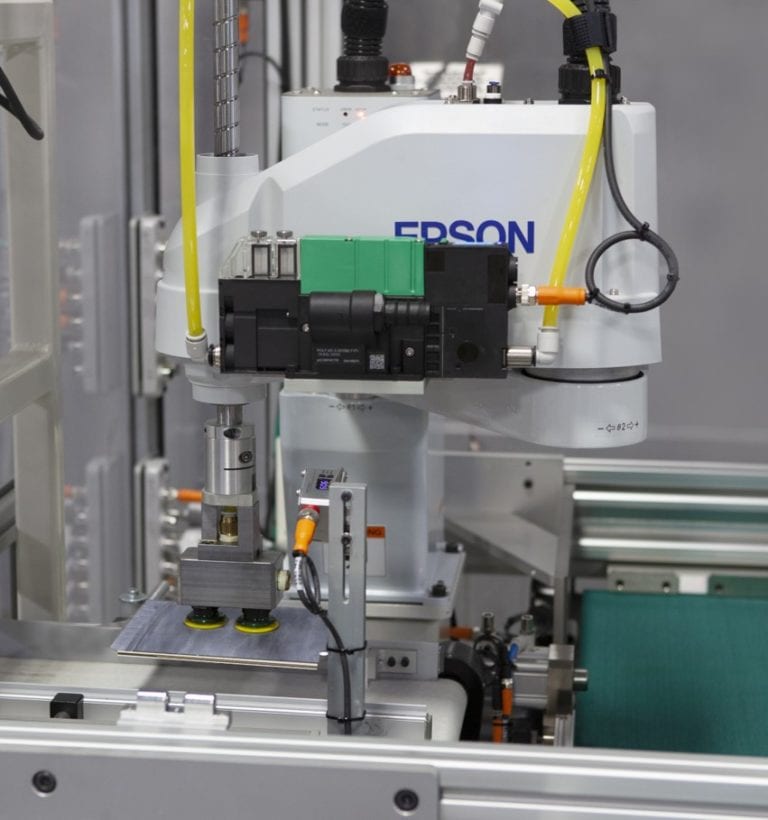

Automation Equipment

- Keyence LJ-X8400 3d laser

- Four empty bins of infeed capacity

- Transfer for full bins to outfeed gravity conveyor

- Allen-Bradley controls

- Lockable reject bin

- Epson robot for part stacking

Machine Performance

- Capacity Requirement: 3 seconds / plate

- Plate size range: 2.5” to 6” wide

- Poke Yoke features: Locked reject drawer w part verification sensor

- Expected Utilization Rate: 24 hours / 7 days

- Equipment Availability: > 85%