Battery Pack Vision Inspection System

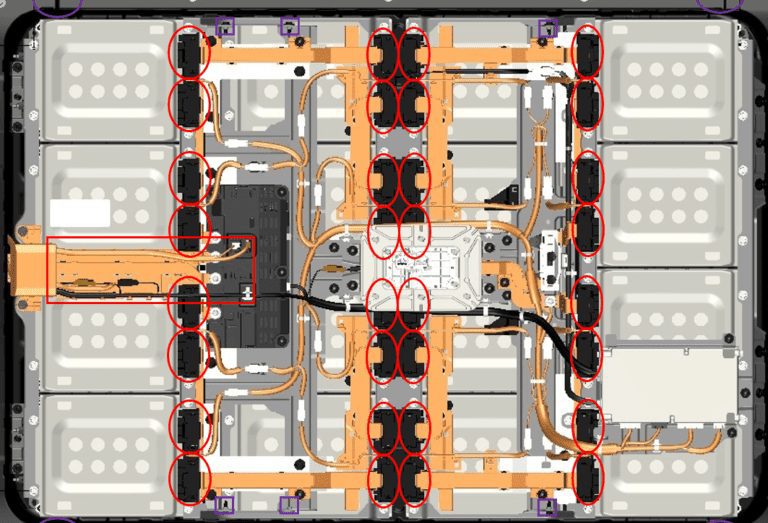

Customer required an automated system to inspect assembled battery packs. The system was designed to be integrated with an existing robot cell to utilize the long process time to minimize any increase to current cycle times. While the robot was doing other tasks, an overhead mounted camera system took pictures of the pack and determined if components were present and in the correct locations. If the packs were good, the robot would come over and complete the process, if the parts were missing components an operator was alerted and given the opportunity to manual fix the pack in the cell or release the pack and send to a holding area for further inspection. The vision inspection took less than 60 seconds to determine if a pack was good or bad. Some of the components the system looked for are listed below.

- Bolts – Presence/Absence

- Bracket presence

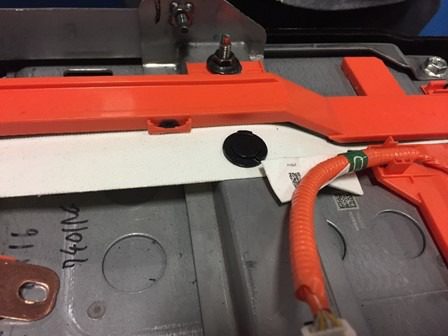

- Cable presence and location

- Connector location

- Keyence 21mp camera

- XG-X Vision Controller

- Allen-Bradley controls

- ABB robot

- Vision execution time: < 60 seconds

- Pack size : 50” long by 32” wide

- Expected Utilization Rate: 24 hours / 7 days

- Equipment Availability: > 85%