Ceramic Material Handling Project

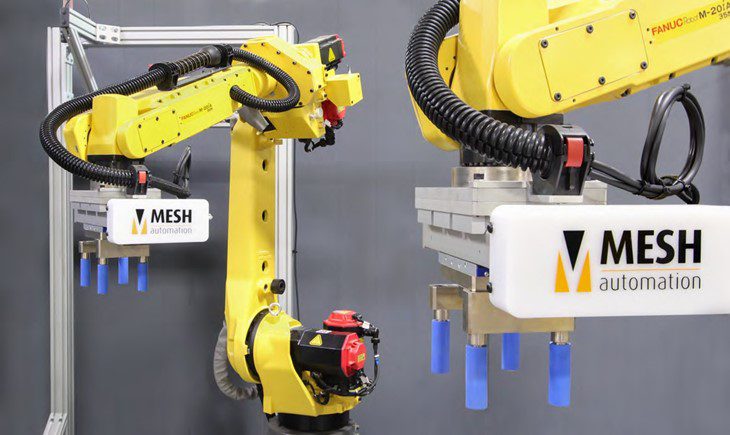

MESH has supplied several multi-million dollar systems for the handling of delicate and odd-shaped ceramic bodies.

Customer Requirement: Robotic machine handling of parts ranging in size from 2 to 12 inches in diameter and ½ to 8 inches tall, requiring the use of a flexible servo-driven end-of-arm tool developed at MESH. Due to the rapid changeovers from part to part in the process lines, MESH recipes are used to set up the production runs automatically.

The MESH control systems enables the user to easily interact with the machinery. We package the SIEMENS controls for ease of use and availability and additionally provide all the interfaces to the customer’s master control systems at the process level and recipe control at the machine level.

Cycle Times: Under 4 seconds part to part

Part Locater: 2D and many times 3D vision is used to accurately identify the location of a part for the robot.