High Speed Robotic Bag Palletizing System

Custom High Speed Robotic Bag Palletizing System

Customer Requirements

Seamlessly integrate a palletizing system into the customer’s current pallet dispenser, slip sheet dispenser, Hamer bag filler, bag accumulation system, pacing and picking conveyor, and a stretch wrapper.

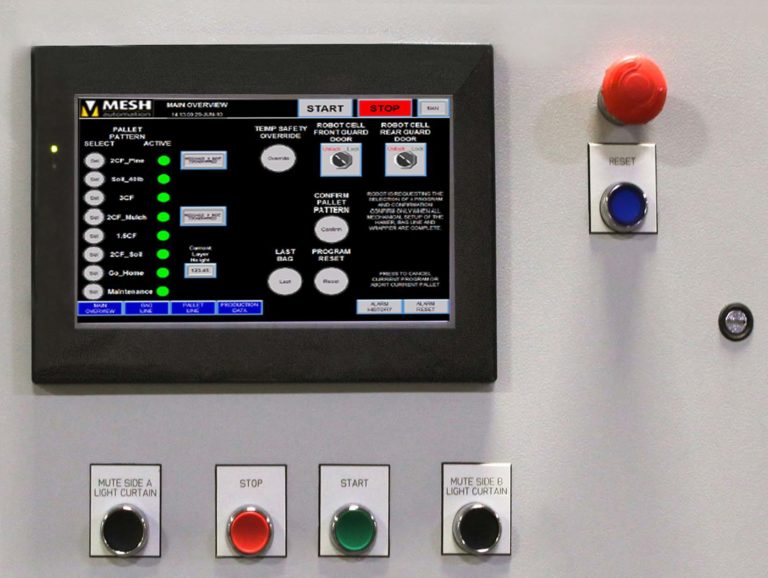

MESH designed, manufactured, integrated, and started up a high-speed robotic palletizing system.

PRODUCTIVITY

Cycle Rate: The Robotic Palletizer palletized at the rate of 24 bags per minute for the 1.5/2cf bags and 21 bags per minute for the 3cf bags.

System Components

- One bag conditioning conveyor was used to flatten the bag and redistribute the material before reaching the robot.

- The conditioned bags were conveyed onto a bag picking conveyor where they were moved to the robot's pick point.

- One KUKA KR180PA palletizing robot with an adjustable claw type end-of- arm tool picked and stacked bags onto a waiting pallet in a specified configuration.

- A stacking conveyor was installed next to the pallet and slip sheet dispenser to bring the pallet into position for stacking.