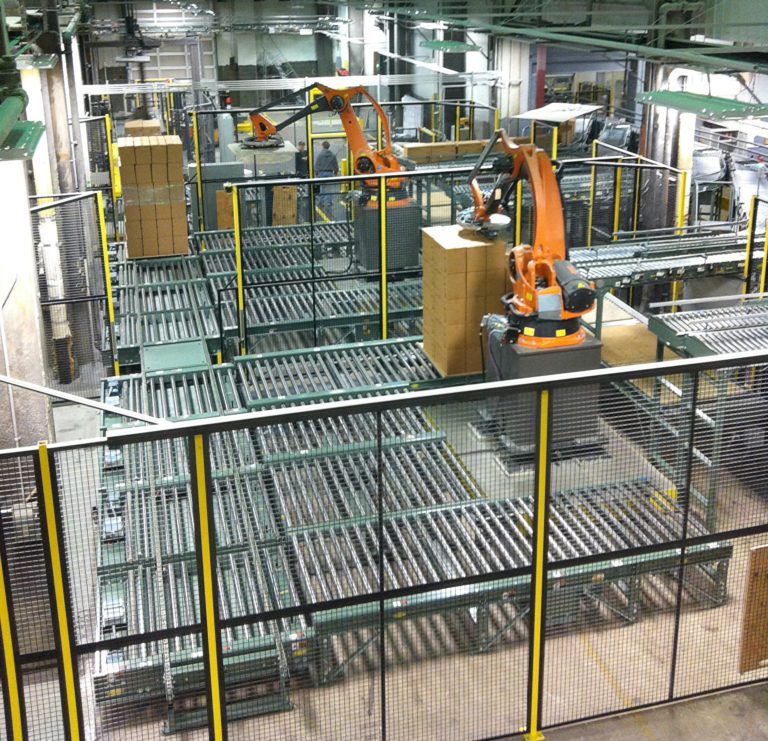

Robotic Mixed Palletizing System

Customer Requirement: A robotic system to receive cases from their incoming conveyors and stack them on a sleigh board, stack a slip sheet, apply stretch wrap, apply a label, and offload the stack.

Solution: MESH engineered, designed, manufactured, and integrated a custom robotic mixed palletizing system.

This system received cases from eight production lines consisting of inline case printers and an incline conveyor feeding one main conveyor trunk. Bar code readers would sort each case into one of eight lanes that entered two robot cells.

Two 4-axis palletizing robots stacked cases based on the bar code and predetermined stacking pattern onto sleigh boards.

Outfeed conveyors conveyed the completed unit load to an automatic stretch wrapper.

Four lanes in, four-unit loads out per robot cell. Customized sleigh board unstacker, conveyor, and sleigh board stacker are included in the system.

- Capacity Requirement: 12 cases/min/robot, 108" load height, 30 unit loads per hour max

- Expected Utilization Rate: 24 hours/7 days

- Equipment Availability: >90%

- Automatic Print and Apply Unit Load Label