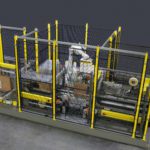

Customized Robotic Case Packing System

Automated Case Packing System

Customer Requirements & Project Info

Customer Requirement: A robotic case packing system that would unfold cases, pick and pack bottles into a case, close and seal the case, label, and offload the sealed case.

System Process:

- Case blanks were loaded into a fully adjustable case erector.

- MESH’s pneumatic gripper assembly gripped and opened the flat case.

- A shuttle system folded the bottom flaps and sealed them with tape.

- A conveyor moved the bottom sealed case onto an accumulation conveyor and staging area in position for robotic loading.

- An infeed conveyor delivered bottles to the robot. The system packed up to three different bottle sizes.

- A 6-axis ABB IRB1600 Robot with a 12 kg payload and 1441 mm reach was used to pick bottles and pack them in the case.

- PIAB vacuum generator end-of-arm tool was used to pick and place up to 6 bottles

- Packed cases advanced to the top flat case sealer and then to labeling and offloading.

Productivity

- 90% OEE

- Cycle Rate: 60 bottles per minute

User Friendly PLC & HMI

- Cell overview with status of robot, safeties, mode

- Alarm banner at top of every screen

- Screen navigation and fault reset at bottom of every screen

- Manual control screen for output devices

- Input status screen for all sensors

- Active alarms screen and Alarm history screen

- Product selection screen

- Product parameters edit screen

- Production counters – total parts processed and cycle time.