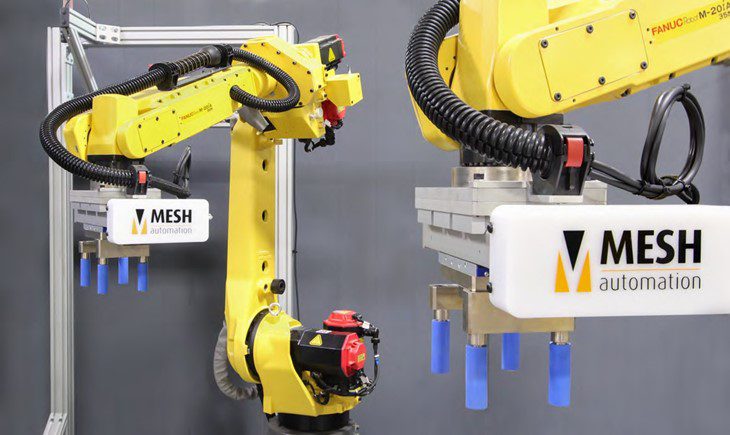

Robotic Case Packers and Case Palletizers by MESH

A robotic case packer and case palletizer system can improve efficiency, labor utilization, safety, and quality on the factory floor. They also increase flexibility for companies that need solutions for special product handling applications and short production runs. However simple or complex your operation is, you need a reliable system that will improve productivity and increase your bottom line.

But how do you know which robotic case packer or palletizer systems will be best for your business? MESH Automation designs and manufactures high-tech, flexible, and reliable robotic solutions as standalone pieces of equipment or fully integrated turnkey solutions from case packing to the warehouse. With your return on investment (ROI) in mind, our team will design and deliver a system to maximize your production and human resources.

Benefits of MESH Case Packer and Palletizing Solutions

Robotic picking, packing, and palletizing solutions go hand-in-hand with one another. With a flexible automation system, you will find that quality, productivity, and workforce capabilities will invariably improve.

MESH specializes in custom designs that are configured to cater to all types of industries and niches. These range from personal care products, building products and food and beverage to pharmaceuticals and medical devices. Automated and robotic solutions are as diverse as the industries that use them.

Some typical benefits of MESH solutions include:

- Highly efficient case palletizer systems that increase production rates, improve labor utilization, improve job conditions (better ergonomics, less forklift interaction…) reduce product waste and improve product and package quality.

- Solutions for small batch size operations – Easy changeovers from the pushbutton changeover to quick change no tool technology. Simple systems for operators to understand what to do in a changeover.

- Flexible designs and specifications that cater to multiple product lines, future product modifications and changes, and altered pallet patterns with customized footprints to optimize floor space

- Systems that can be integrated with planned or existing equipment such as case erectors, case sealer, labeler, stretch wrapper, or conveyor systems.

- Product flexibility – Robots that can case pack rigid and non-rigid containers in a variety of packaging configurations. Single or multiple products picks to improve on package throughput.

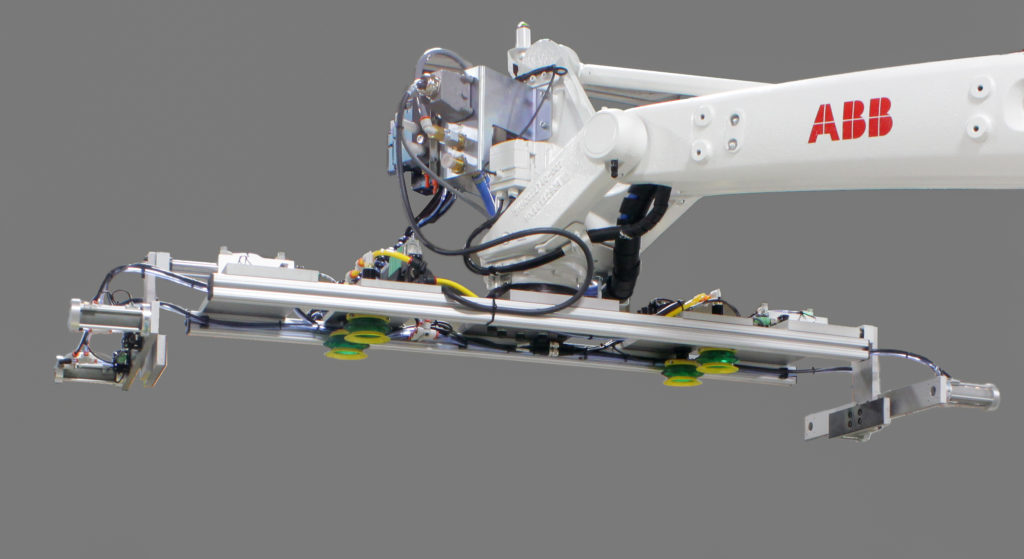

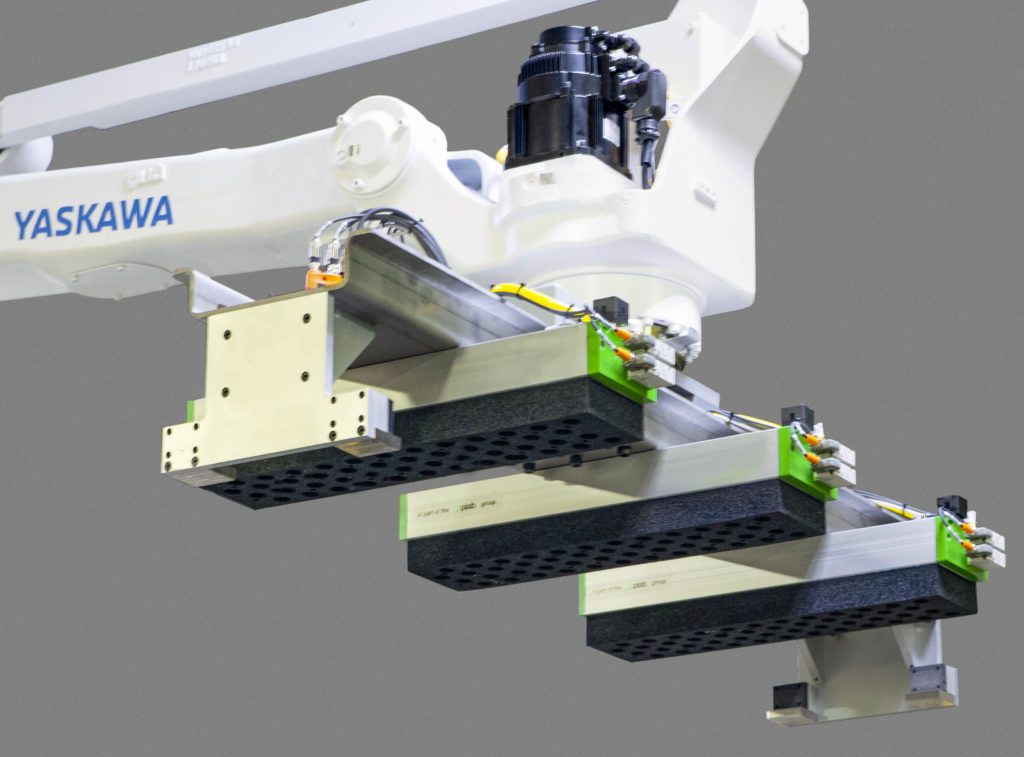

- A comprehensive range of robot loading arms that suit specifications for speeds, unit loads, and layout requirements

- Fewer risks of product damage because of the accuracy and control over the acceleration and deceleration of the product through the use of robotics.

Capabilities of Robotic Case Palletizers

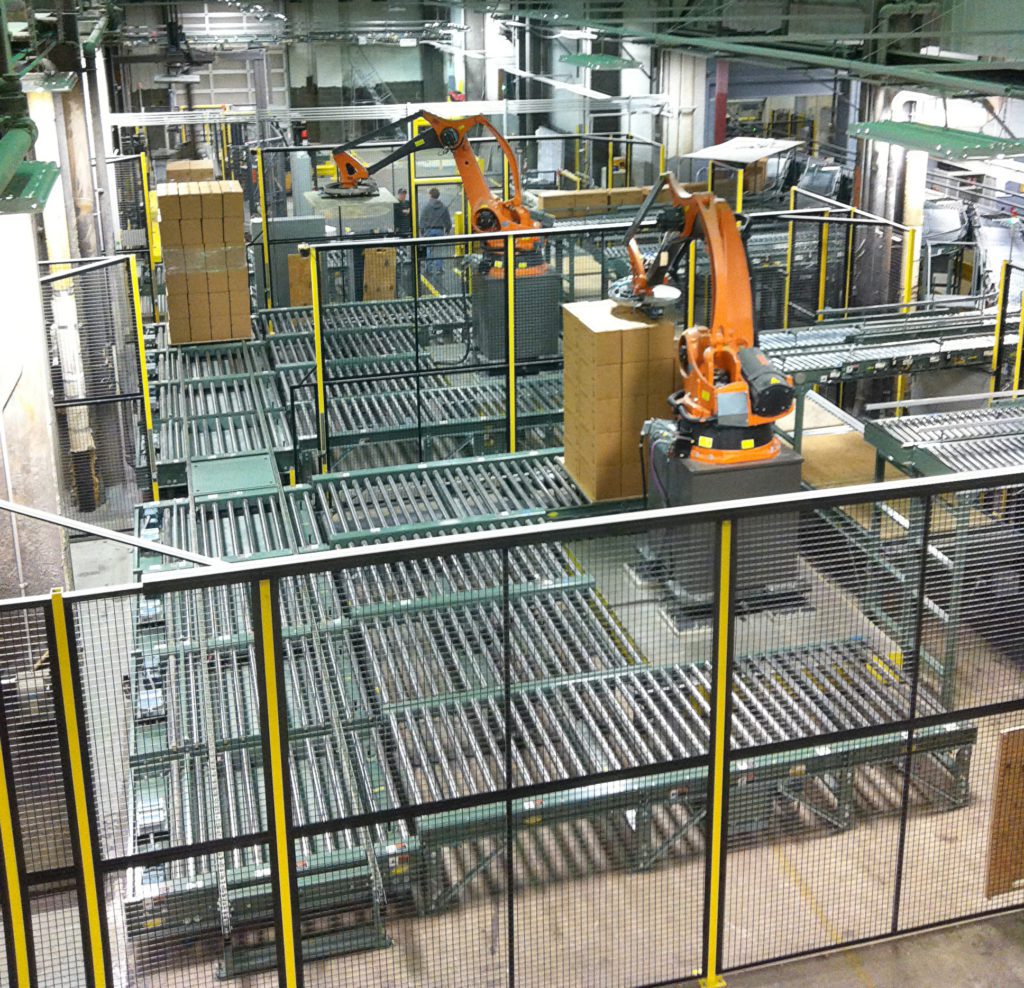

- Robotic case palletizers by MESH can easily handle up to four infeed conveyors and their individual SKU and up to four stacking locations in one cell. See our MACPal offering

- Mixed load palletizing is offered by MESH using their specially designed MACPalOF

- Sortation is sometimes necessary for certain systems. A robotic case palletizer can work seamlessly with sortation conveyors or dedicated lines from each production machine.

- Cases per minute speed is usually forefront of most specifications. It is best to consult with MESH sales and applications engineers to understand the productivity needs and options available. Robotic systems with their flexibility can typically perform at 3 – 4 times the rate of an operator

- Pallet stack height – Most modern palletizing robots if configured correctly can stack up to 108” tall.

- Pallet or stack envelope (length and width) – Most stacking configurations are designed to fit into a 48” x 40” envelope, but robots are very flexible and can easily accommodate most requirements within reason.

- Palletizing or Unitizing – Unitizing is stacking cases on a returnable sleigh board and the finished goods are taken away via clamp style forklifts. Palletizing is stacking cases on pallets that are included during storing and shipping. Consult with your MESH sales engineer for the pros and cons of each.

- Dunnage – With automatic slip sheet dispensers and the correct end effector MESH can accommodate most slip sheet requirements. MESH can also provide systems for corner boards prior to stretch wrapping or stacking inside a sleeve.

- Safety – MESH designs our robotic case palletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

Capabilities of Robotic Case Packers and Case Openers

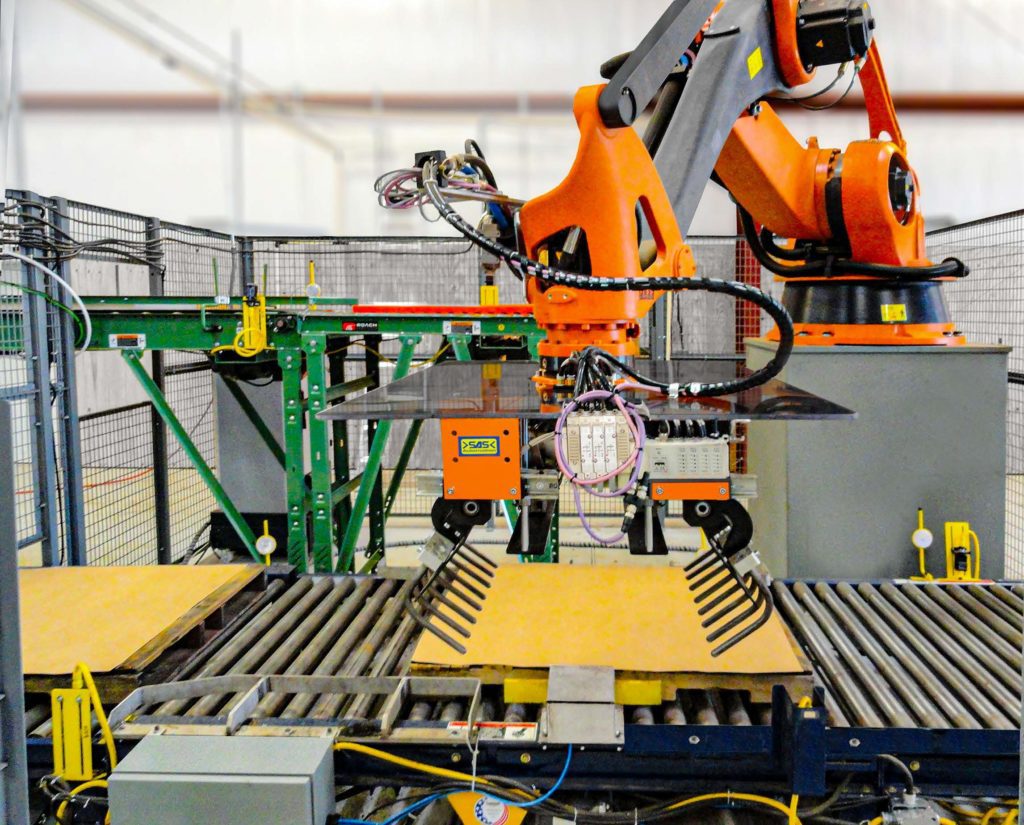

- Sophisticated loading arms for case packing are able to perform absolutely precise movements with control over acceleration to protect every type of product. Modular designs are scaled to suit product contents and weight as well as the speed of the case-packing operation.

- Robotic case packers can tilt the case during packing so that loading is tight.

- MESH’s robotic case packer can be integrated with existing case erectors, case sealers, and case labeling functions to fully automate packing system solutions.

- MESH’s MACPac is a case opener, taper, and packer all in one. Our design optimizes floor space and speed by integrating all necessary functions in a clean and precise package with one control system.

- Product conveyor systems provide material handling to and from MESH’s robotic case packer are highly customizable and are integrated with the machine’s control to optimize speed and function.

- Safety – MESH designs our robotic case packers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

Case Palletizing FAQ

How do robotic case packers work?

Robotic case packers fulfill the entire packing process. They queue products for packing and then feed containers for packaging into position. The robot, equipped with an end of arm tool (EOAT), picks products from a conveyor and places them gently into the required package. Labels, insert cards, and special promotional items are easily integrated into the system if needed.

How do robotic case palletizers work?

Robotic case palletizers transfer packed cases or containers from conveyors onto pallets quickly, placing them accurately layer by layer, depending on the pallet patterns required. These patterns can be programmed into the robotic palletizer and changed at any time. Pallet entry into the robotic case palletizer can be handled in many ways, including the robot. In addition to handling pallets, these robots can also handle slip sheets and tier sheets using a custom-designed EOAT for automatic pallet handling.

What advantages do robotic palletizers have over conventional palletizers?

Unlike conventional palletizers, robotic palletizers can process multiple SKUs and layer configurations at any given time. Conventional palletizers can be rough on the product. Robotic palletizers handle product more gently than a human.

What advantages do robotic case packers have over conventional case packers?

Robotic case packers by their nature are flexible and allow a wide variety of products to be packed with little to no changeovers. Their compact and highly developed design allows for a small footprint for their comparable operation. Case openers can be integrated easily with the robotic case packer (MACPac) for a compact footprint. Robots are ideal for handling sensitive products.