Case Studies

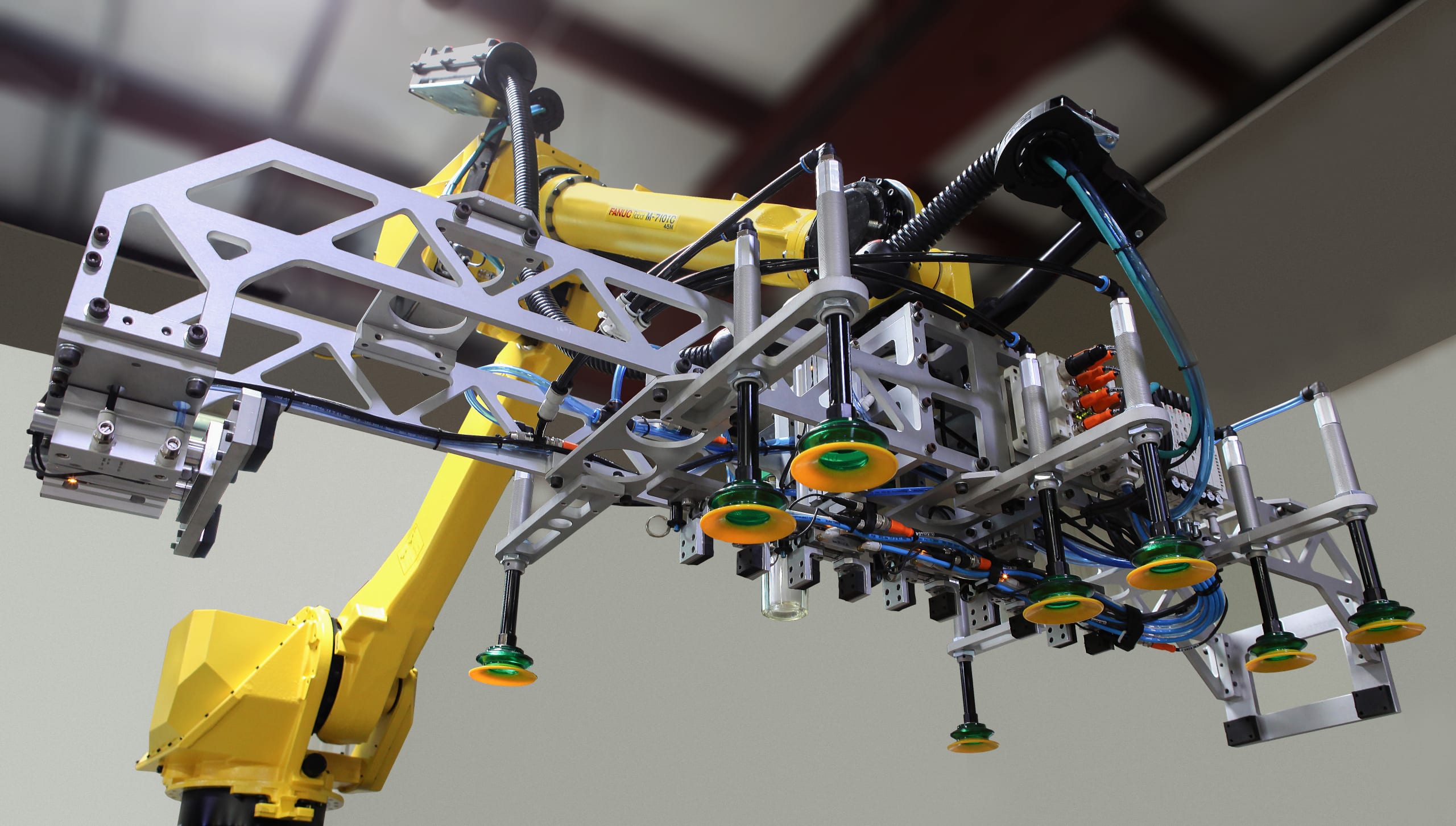

Robotic Case Palletizing Project

Robotic Tote Palletizing Project

Robotic Palletizing of Bottles

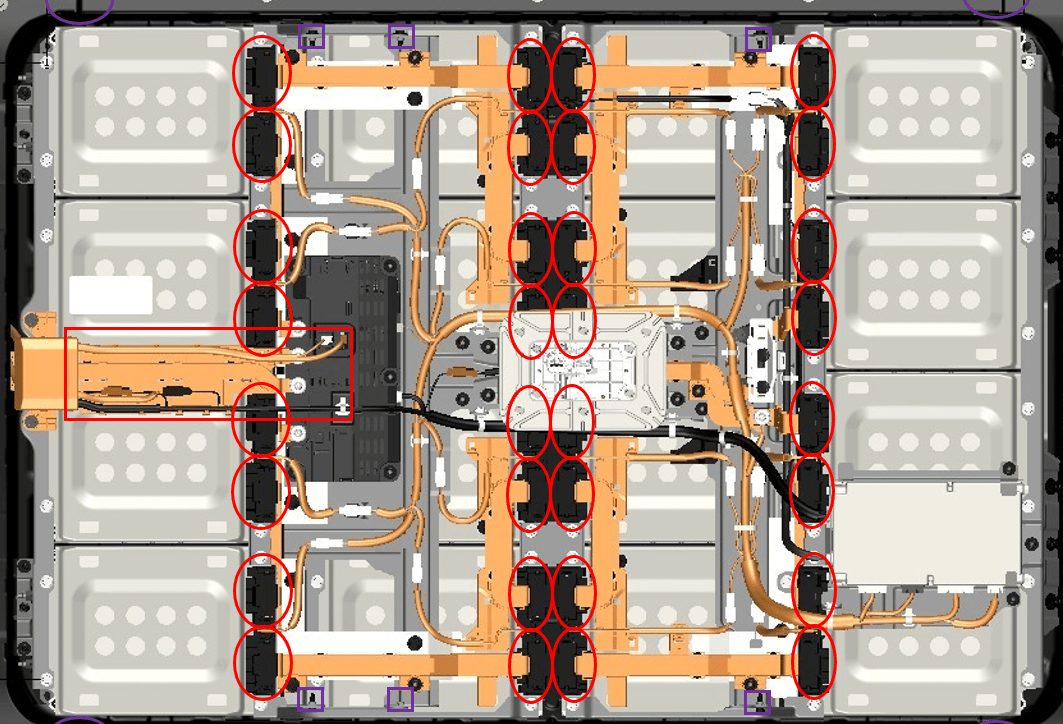

Battery Pack Vision Inspection System

Battery Plate 3D Vision Inspection Machine

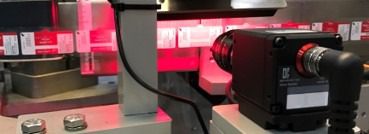

Inline Pharmaceutical Label Inspection

Sort by Expertise