Case Studies

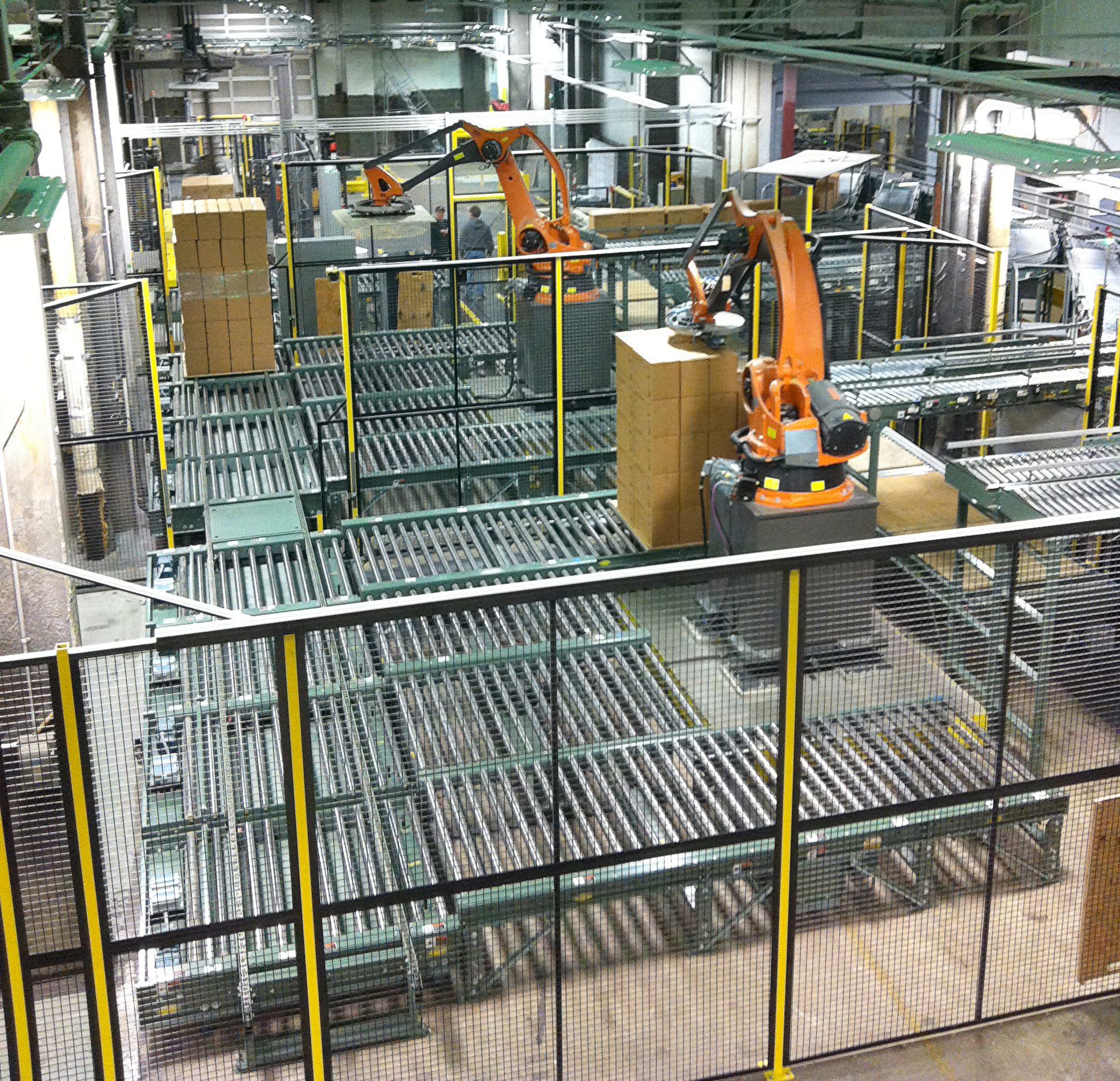

Robotic Warehouse Order Fulfillment System

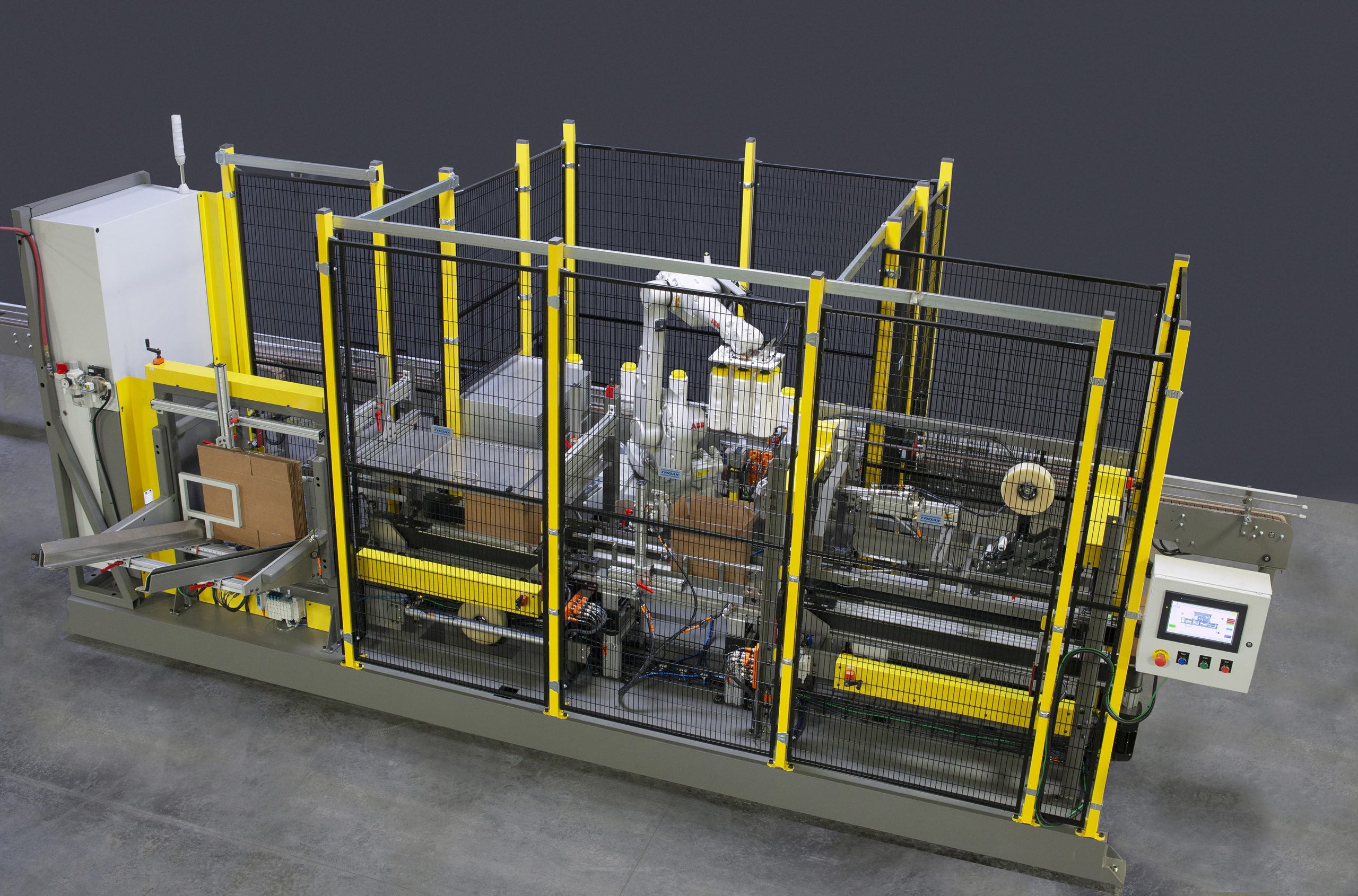

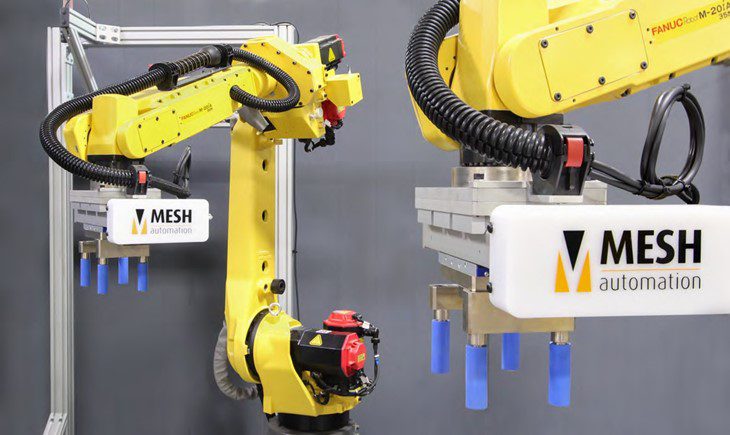

Customized Robotic Case Packing System

Case Packing with Product Verification

Ceramic Material Handling Project

Custom Automatic Bag Palletizer Cell

Robotic Mixed Palletizing System

Sort by Expertise