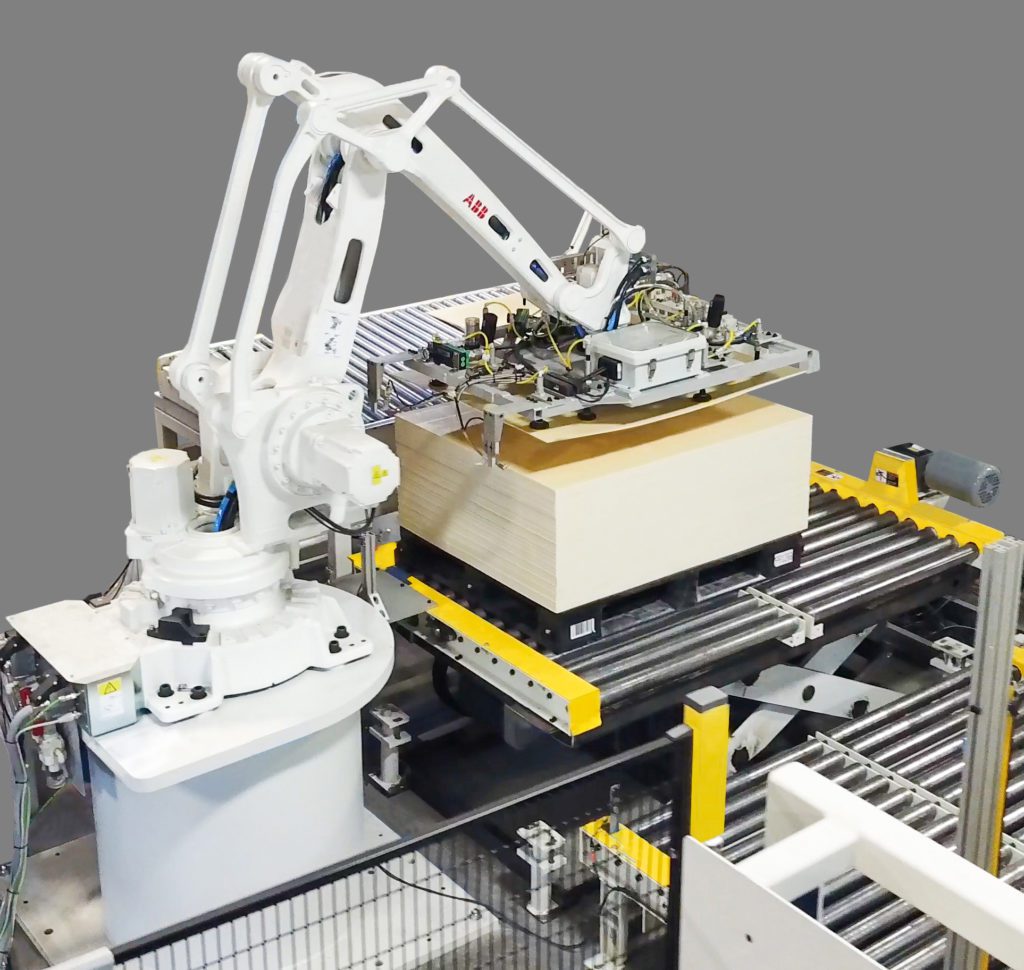

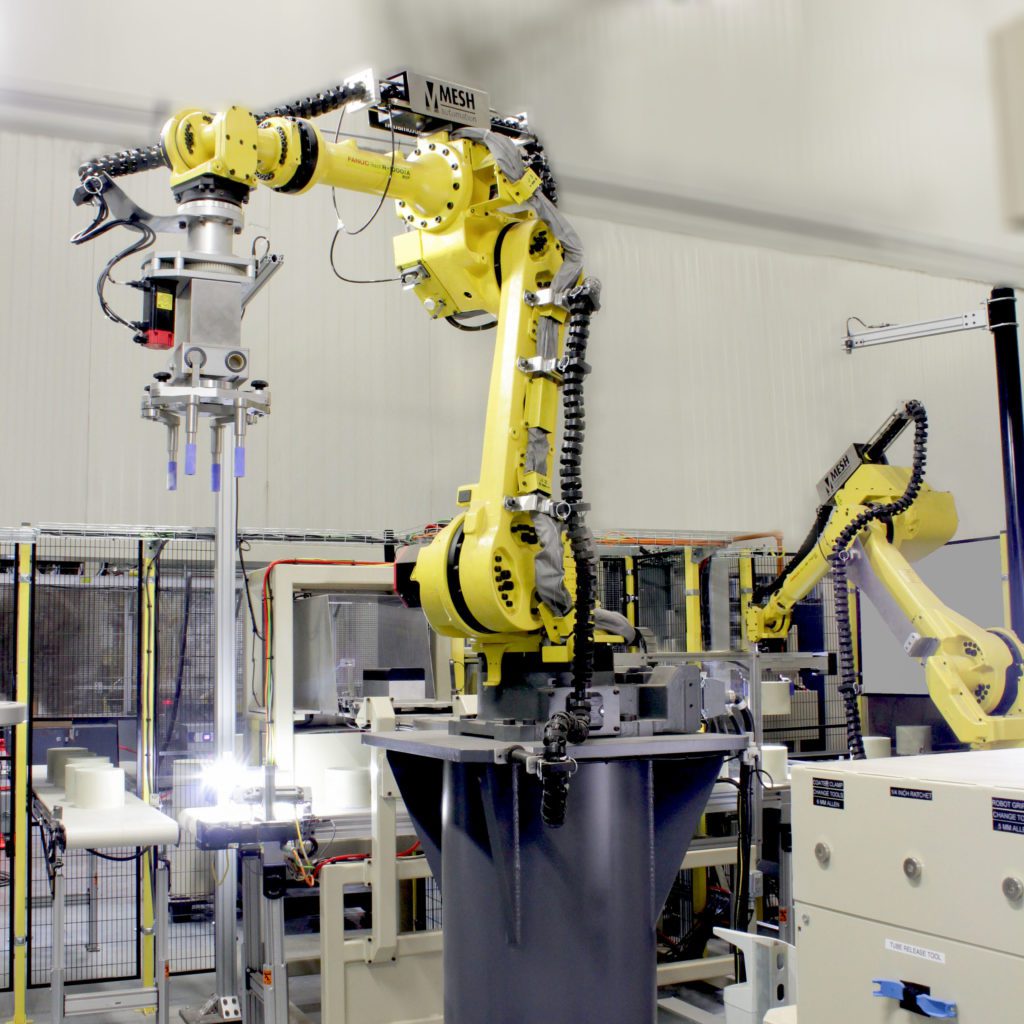

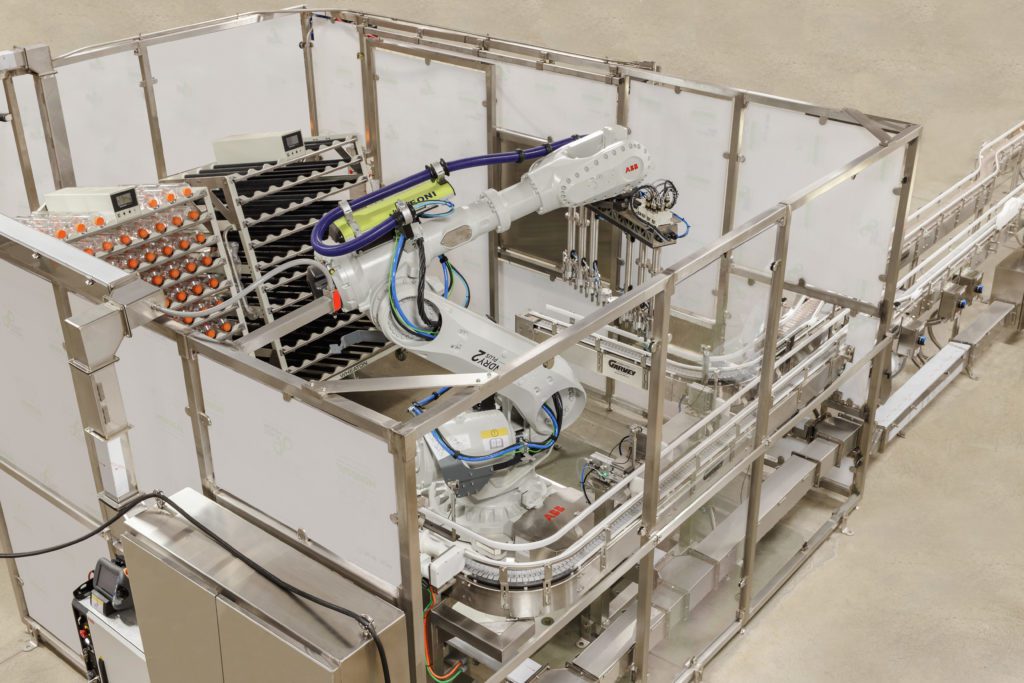

Our expertise in feeding raw materials or picking and placing raw materials or work in process components into a process stems from our 23 years of designing and building custom equipment that inevitably involves handling a raw material or work in a process component.

The variety of products that MESH has handled is quite large from soft, light, and pliable to large, heavy, and rigid. Product damage from obvious to subtle is always a concern as well as feeding speed and orientation.

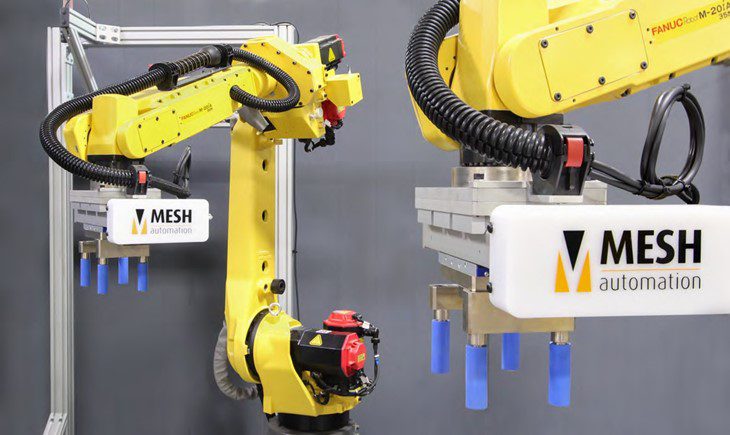

MESH has used robots, motion-controlled devices (gantries and other single axis slides), vision-guided conveyor systems, vibratory systems, centrifugal systems, robotic bin picking from a tray, robotic bin picking from a disorganized array, and cartridge feeders to sort, feed, and pick products.

The use of automated transport of raw materials from the warehouse to the feeder is now being employed at many modern manufacturing facilities. MESH has experience in setting up the feeder in feeds for seamless AGV loading and can provide the AGV.

Benefits of Robotic Feeding and Picking Systems

When using automated methods the benefits fall into one or more of the following categories; Feeding systems are no different. The time to automate has never been greater because the technology is proven and the costs to complete projects typically have great returns on their investment.

- Improved labor utilization

- Reduce injuries

- Improved labor morale and retention

- Reduced variable and fixed costs (waste reduction, reduce material handling costs (forklifts) and other)

- Reduced waste with better efficiency on the manufacturing line

- Improved process control and the resultant improved product quality.

- Better customer retention through a positive impression and controlled process.

- Improved operating hours and throughput – robots don’t call in sick

Discussion of Robotic Feeding and Picking Systems

- Robotic Feeding systems can be broken into three main categories

- Robotic picking from a pre-organized group of products such as a tray with pockets for each product.

- Robotic bin picking from a disorganized array of products (bin full of random parts)

- Vision enhanced robotic picking where products are spread out flat on a surface via vibration or other methods and vision is used to find and guide the robot gripper to pick it up

- Regripping is often used on the above methods to regrip the product for more accurate and repeatable product placement in the gripper.

- Vibratory feeders are often seen in the form of bowl feeders, but can also be linear in nature or used to reorient product on a surface for robotic vision picking

- Centrifugal feeders are typically used for a product that needs high throughput and cannot be vibratory fed. Products like coffee K-cup or other soft pliable products.

- Cartridge feeders are custom devices that allow for a stack of products to be placed into the system and one product is ejected from the top or bottom of the stack and placed in a position ready for a gripper to grab. These types of feeders can have multiple stacks on a rotary device for more accumulation or a single stack. The product must have stackable characteristics preferably without nesting and the product height is small so a lot of products can be placed in a stack.

Automated Feeding & Picking FAQ

Click here to download our brochure and learn more about MESH Automation’s complete industrial and factory automation solutions.