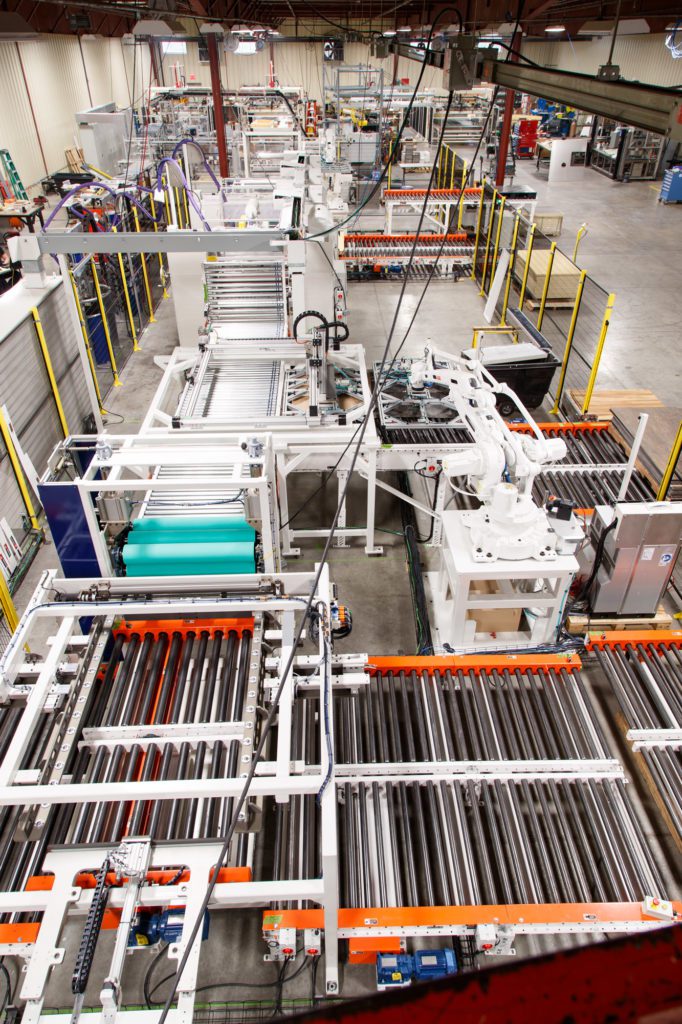

Automated Conveyor Systems

Automated conveyor systems are many times the best choice for moving raw materials, work in process and finished goods. Conveyor system design and type are important to specify correctly to assure that your product does not get damaged, you are getting the best value and the conveyor system is appropriate for feeding your other automation equipment.

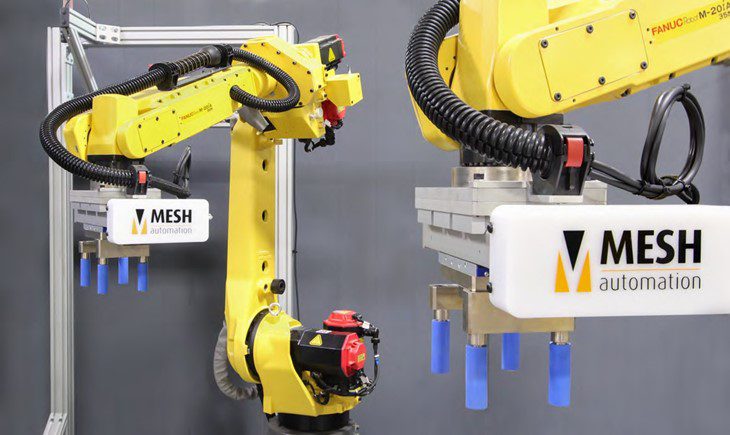

Choosing the right type of conveyor requires experience like the professionals at MESH have. MESH manufactures a lot of their conveyors and will develop, build and commission the conveyor control system using their knowledge and proven software techniques to give you the best value and protect your product.

Because MESH is an experienced automation equipment integrator we know how to feed and present your product or raw material to each piece of equipment whether that is a process line, feeder, packaging equipment, existing conveyor system or end of line AGV.

How to Choose an Automated Conveyor System

Many factors should be considered when specifying an automated conveyor system such as;

- Available footprint.

- Conveyor speed, and load capacity

- Backpressure control,

- Conveyor width

- Conveyor side rail system

- Type of conveyor

- Plastic chain and type

- Belt (slider bed or roller bed)

- Belt under roller

- Lineshaft roller

- DC motor zoned roller

- Chain driven live roller

- Single or multi-lane chain conveyor – aka drag chain

- Elevation and floor footprint considerations (forklift aisles, pass thru’s, etc)

- Material construction techniques (to manage corrosion, washdown high temp swings, or other requirements)

- Control system specification – brand of PLC, HMI size and location, panel locations, starters or drives

- Installation specification – cable tray enclosed or open, conduit, drip pans, local disconnects, netting for product fall protection.

- Other considerations like maintainability, component sourcing, jam clearance, walkovers, lift gates.

- Pallet construction and size range.

MESH Automated Conveyor System Customizations

Many conveyor systems need auxiliary equipment to make them work in the manner you need. MESH designs and builds many of these devices such as but is not limited to:

- Diverters

- Mergers

- Slip sheet dispensers

- Pallet dispensers and Pallet stackers

- Stackers for product or raw materials

- Accumulators

- Chain transfers

- Reject and product pushers

- Rotating accumulator tables

- Accordion conveyor

- Conveyor lift sections for pass-thru

Additionally MESH can integrate devices like weigh belts, labelers, banders, shrink wrappers, case packers, bar code readers, and other equipment into their conveyor and conveyor control system.

Automated Conveyor System FAQ

When should I use plastic chain conveyor or roller?

If your process requires curves (90 degree, 45 degree or custom), while keeping the product moving and in the same orientation, plastic chain shines above rollers and belts. The plastic chain is also very gentle on your product by conveying it very smoothly and flat. The plastic chain comes in many widths, friction surfaces, and flexibility, but has limits in load-carrying ability and speed. Some plastic chains can go over a nose bar to minimize transfer gaps, unlike rollers. Roller and belt media are usually less costly per lineal foot compared to plastic when the width of the product starts to get above 6”.

What is the best conveyor to use for my pallet conveyor system?

The best conveyor for empty or loaded pallets is a properly rated chain-driven live roller or multilane chain conveyor. Which type is determined by the pallet configuration you have and the direction of travel.