3D Vision Bearing Inspection Machine

3D Bearing Inspection Machine

Project Details

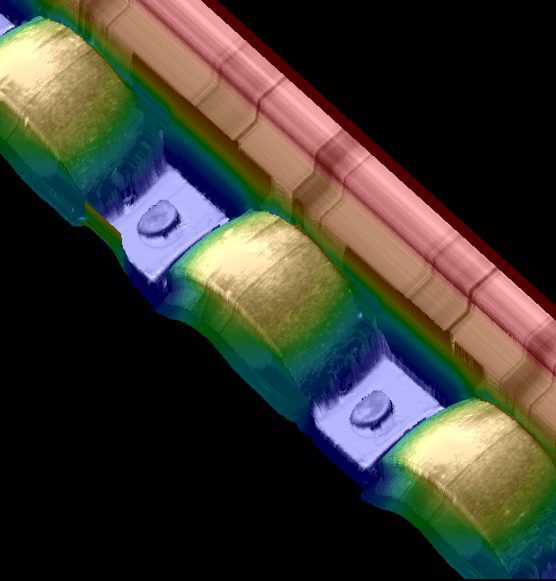

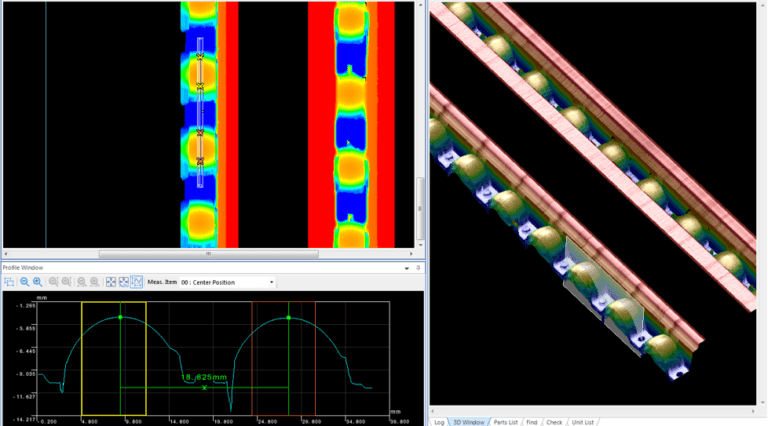

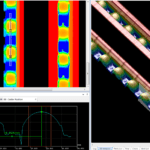

Problem Statement; Customer required an automated machine that could load, unload, and quarantine out of spec roller bearings. Inspection was primarily of the inner cage of roller bearings from 30mm – 150mm OD. The inspection criteria required 3d laser inspection of both sides of the bearing and a controlled rotation of the bearing so that the entire cage was scanned. Cycle rate was proven at <6 seconds and the defects detected were as described below;

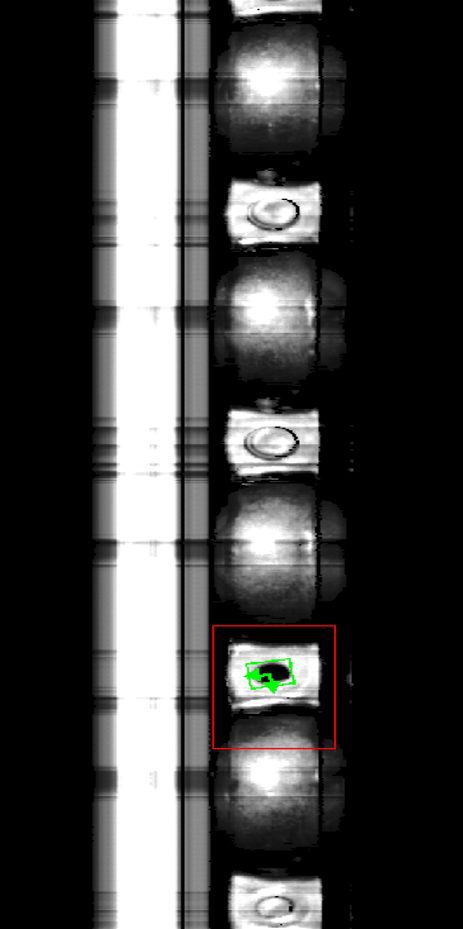

- Cage rivet presence

- Cage rivet height

- Missing ball

- Double cage

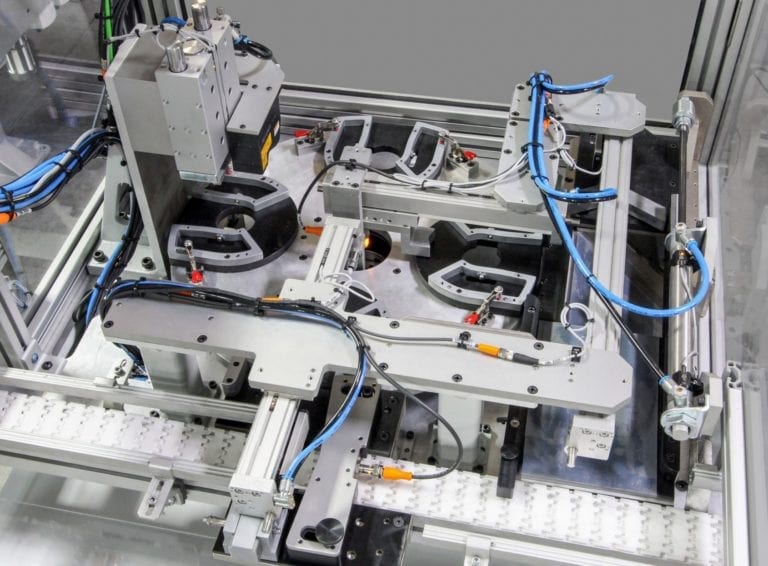

Automation Equipment

- Keyence LJV-7080 3d laser

- Four position rotary index dial with quick change tooling.

- Servo motor and pneumatically engaged spindle for controlled turning of the bearings

- Siemens controls

- Lockable reject bin with Poke Yoke features.

- Load and unload mechanism for interface with the customer supplied Flexlink style conveyor.

Machine Performance

- Capacity Requirement: <6 seconds / piece

- Bearing diameter range: 30mm – 150mm

- Poke Yoke features: Locked reject drawer w sensor detection

- Expected Utilization Rate: 24 hours / 7 days

- Equipment Availability: > 85%