Robotic Stacking Systems

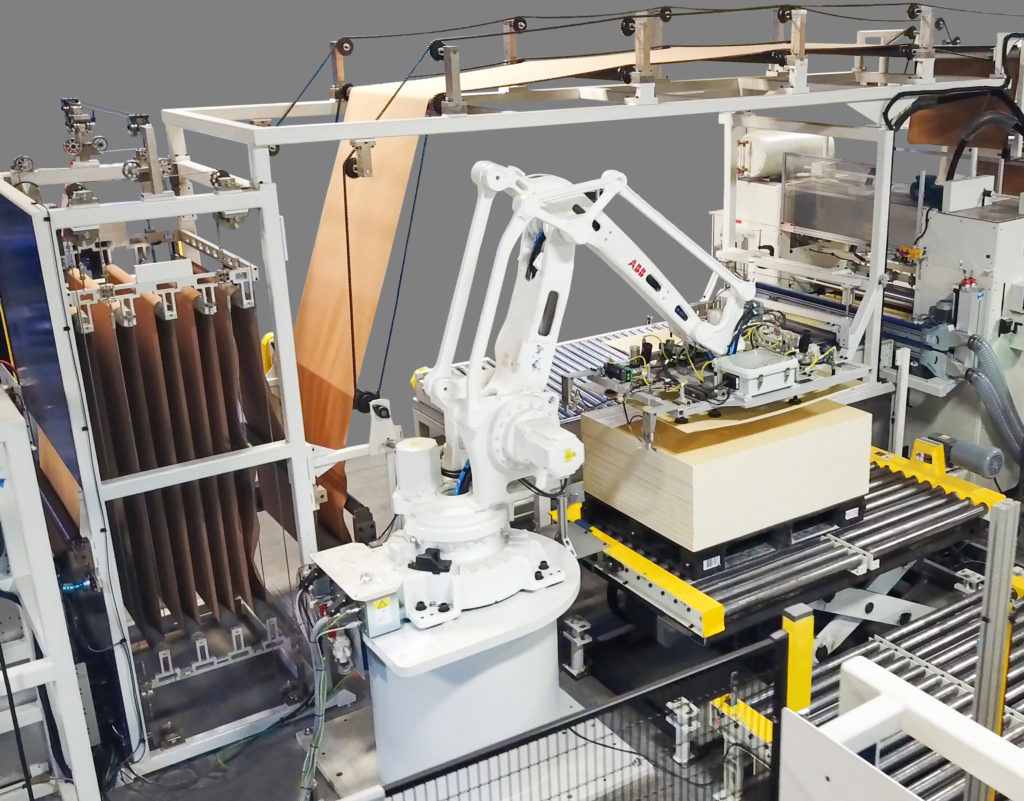

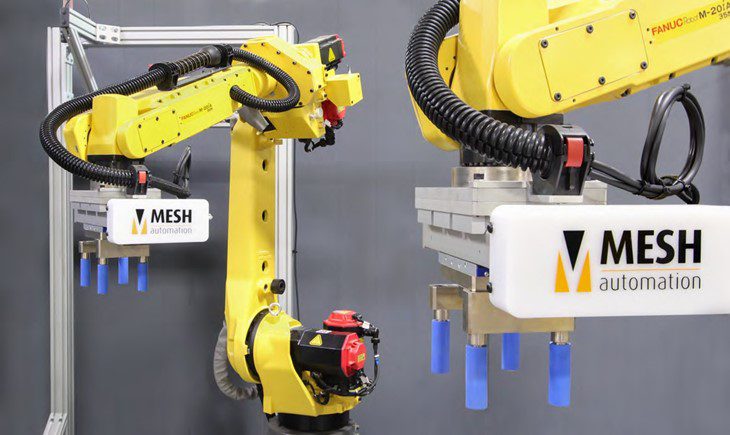

MESH has designed and built robotic, gantry, and traditional product stackers and destackers. Picking the correct system is dependent on the rate, size of the product, the rigidity of the product, and requirements of the pallet and pallet exchange. MESH has achieved +- 1mm stacking accuracy using a robot or gantry.

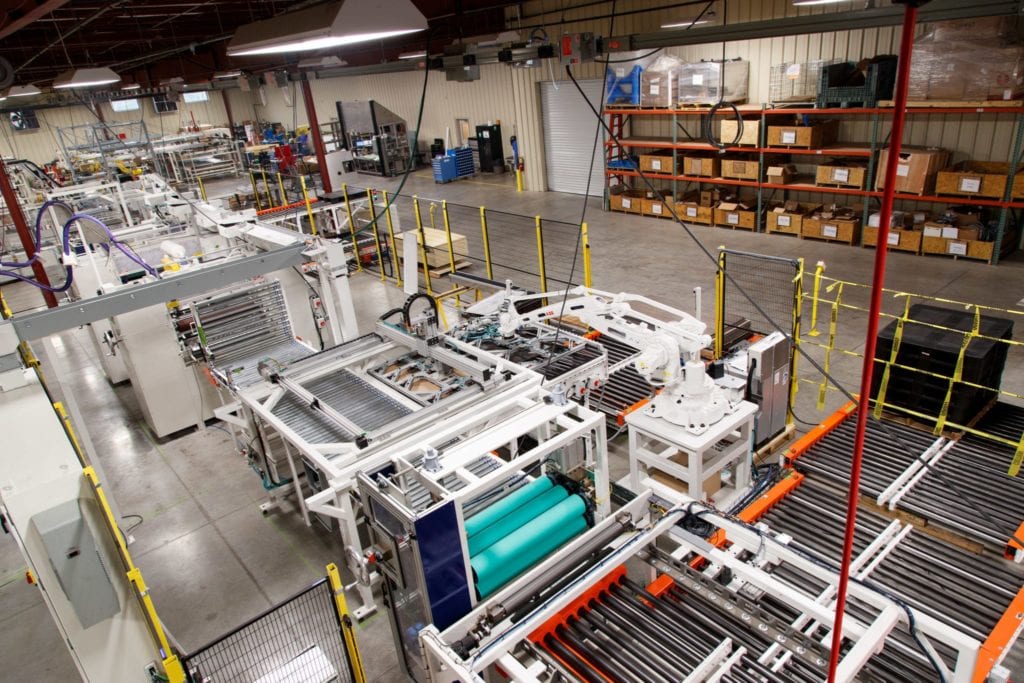

It all starts with the material feed system. Whether this is a roller conveyor, drag chain, or other feed system controlling the speed and position of the material is critical.

If a robot or gantry is chosen the end-of-arm tool design factors greatly into the performance and long-term reliability of the system.

Other features such as automatic rejects, bypasses, pallet dispensers, slip sheet dispensers, pallet exchange requirements all must be considered with due diligence when considering the entire system design.

MESH is your one-source supplier of the right system. Please look into our pre-engineered robotic systems, pallet dispenser, end of arm tools and slip sheet dispenser products.

Benefits of Robotic Stacking Systems

The fact is that automated robotic stackers and destackers will dramatically reduce labor costs, reduce injuries, improve product or package quality, help with seasonal labor shortages, and reduce the square footage needed for the same operation done manually. Using raw manpower or forklifts are the traditional way to manually move and stack or destack materials. Pick and Place robots will move and stack most materials without the use of manual labor and minimize forklift interaction.

Stacking and destacking materials by hand is labor-intensive and also a big source of workplace injuries. Material handling automation equipment such as a robot or gantry programmed for stacking or destacking are easy wins for your operation and will pay for themselves very quickly. System design needs to be simple so maintenance can be simple and easy to understand. Operator functions to help with order fulfillment, special needs, or fault recovery need to be taken into consideration in addition to an intuitive operator interface or HMI.

MESH has this experience and it shows in our equipment ruggedness and simplicity.

Capabilities of Pick and Place Robots and Robotic Stacking Systems

Automated material handling solutions using pick and place robots and automated gantry stackers and destackers are much more efficient than the labor-intensive models used by a lot of manufacturers. The time to automate has never been greater because the technology is proven and the costs to complete projects typically have great returns on their investment.

- Robotic sheet stackers and destackers can be straightforward in some cases and downright difficult in others. Sheet affinity to each other through static, suction, oily surfaces can be a real problem. MESH has proven solutions for most of these.

- Stacking and destacking systems usually have a material handling infeed and outfeed that can be designed using conveyor, automated guided vehicle, or gantry-based systems. MESH has experience in these feeding systems and will explain to you the pros and cons of each for your unique system.

- Automated conveyor systems are not your most glamorous of material handling systems but for a lot of products and facilities, they are the most cost-effective. Most systems have one or more conveyors but choosing the right type of conveyor requires experience like the professionals at MESH. MESH manufactures a lot of their conveyors and will develop, build and commission the conveyor control system.

- Stack height – Most modern robots if configured correctly can stack up to 108” tall.

- Dunnage – With automatic slip sheet dispensers, slip sheet stackers and the correct end effector MESH can accommodate most slip sheet, tray, or other dunnage requirements for your stacking operations.

- Safety – MESH designs our robotic and gantry destackers, stackers, and palletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

Robotic Pick and Place/Stacking FAQ

What are the key reasons companies choose automated stacking?

Labor issues are in the forefront of most automation decisions. Most manual handling jobs are high speed, result in repetitive motion injuries and are undesirable (hard to find workers). Human interaction with forklifts are accidents waiting to happen. Robots and other automation along the packaging line eliminate these labor issues forever.

When do you recommend a Gantry over a robot for flat sheet handling?

Gantry’s can handle large format sheets better than robots and can sometimes be more cost-effective when payloads and size start to max out the standard robot offerings. Additionally, if the pick location is far from the place location, a gantry may be a better option.

When is a robot the right automation tool for flat sheets?

Robots have the best value when six axes of motion are needed. This often comes into play on most machine tending operations or when an angle motion is needed to separate sheets during destacking.