Autonomous Mobile Robots integrated by MESH Automation

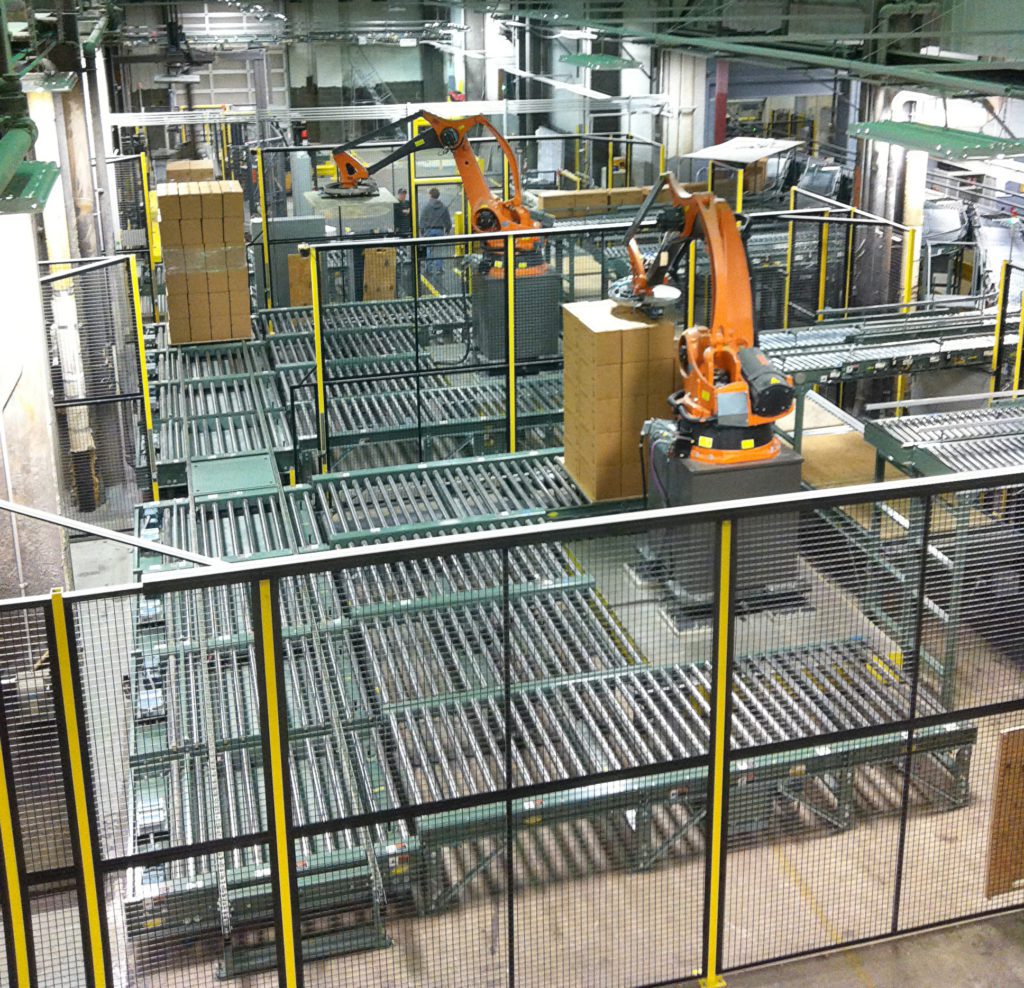

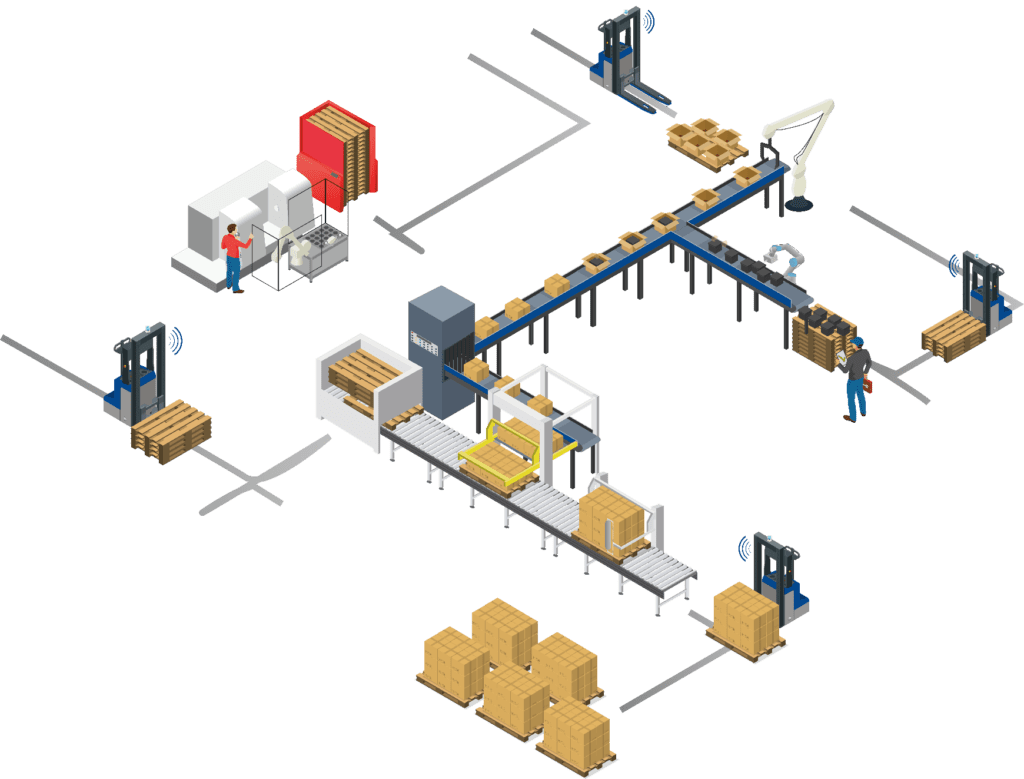

Autonomous Mobile Robots (AMR), are driverless programmable powered vehicles. The AMR can operate autonomously and safely around humans. These machines as integrated by MESH Automation are increasingly becoming the best solution for moving finished goods or raw materials between machines or between production and warehousing. MESH’s multiplatform controls experience, high-level software development expertise, and experience in the field allow us to give you the best turnkey solution and integrate it seamlessly.

Integrating AMRs can be very complicated. MESH brings professional project management and the ability to overcome technical challenges which are essential to achieving a successful AMR project. Because our core competencies and DNA are in robotic automation we bring a distinct multidisciplinary advantage over others who deliver one-dimensional approaches to material handling problems.

MESH offers a full line of AMRs with turnkey integration services that are proven in the industry.

Capabilities of Autonomous Mobile Robots integrated by MESH Automation

AMRs typically have a payload range of 60kg to 1500 kg depending on the brand. They are designed to handle simple transport delivery and routing operations in a collaborative and safe manner so your employees can perform higher value jobs. Software and controls allows them to intelligently navigate around people and unplanned obstacles. Docking accuracy is typically between 8 and 25mm depending on the options and brand.

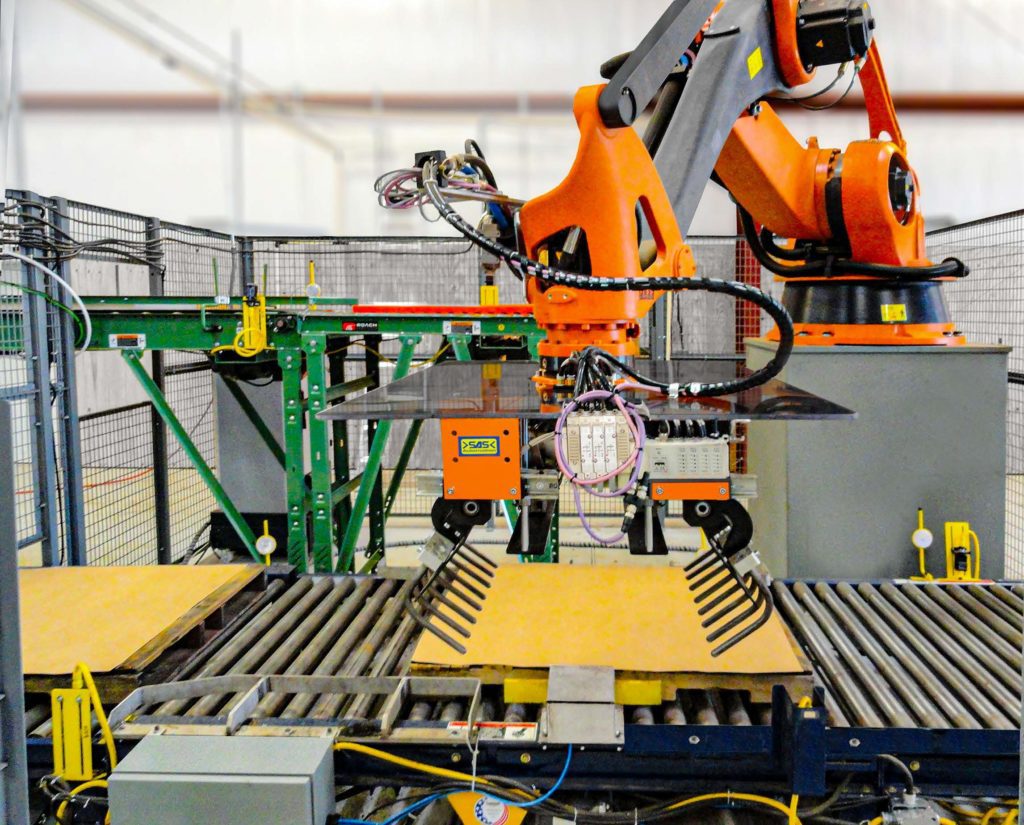

MESH has the accessories to help the AMR integrate with existing equipment such as;

- DC Conveyor top by MESH powered by the AMR.

- Yaskawa, or FANUC cobot mounted and powered by the AMR and programmed by MESH

- DC powered lift tabletop by MESH

- Custom solution such as electric pushers, blade stops and other unique AMR top solutions.

- Battery type options

Benefits of Autonomous Mobile Robots integrated by MESH Automation.

Autonomous Mobile Robots or Automated Guided Vehicles and driverless forklifts integrated by MESH Automation have many easy-to-justify benefits.

Labor utilization – AMRs and modern driverless forklifts do not need any labor to operate and if properly integrated and specified by MESH Automation, will operate lights out 24 hours a day. AMRs never take a rest or slow down as the day progresses.

Operating cost improvement – AMRs and modern driverless forklifts only require electric utilities and are more efficient in their energy usage than forklifts. No more propane or fuel considerations or infrastructure. Maintenance on forklifts are significantly greater than modern AMRs and driverless forklifts.

Consistent call-up times – Unlike an AMR, waiting for a material handling forklift driver to show up can cause production delays

Safety improvements – Standard forklifts have a horrendous safety record. Accidents with forklifts are also severe and life-threatening. AMRs and driverless forklifts are significantly safer than forklifts and promote a safe environment for your employees.

Footprint reduction – Compared to conveyorized systems or transfer carts an AMR solution frees up floor space and offers more flexibility for future growth or product changes.

Reduction in warehouse floor contamination – Hydraulic oil from forklifts not only is a safety hazard but needs cleaning up. In general, hydraulics are limited or eliminated on some AMRs. Operator abuse, the leading cause of repair needs, is also minimized on AMRs and driverless forklift trucks.

Autonomous Mobile Robot FAQ

My production lines are not ready for an easy AMR interface. Does MESH have solutions for this?

Yes, MESH is an experienced automation integrator and designs and builds automation equipment as one of their core competencies. This experience and skill set is ideal for finding and executing solutions to your interface opportunities.

When should a driverless forklift AMR be specified?

Driverless forklift style AMRs can pick up pallets that are on the ground and can deliver them at any elevation needed if it is 1 meter or less. If a requirement of the system is to pick up pallets at ground or very low elevations, then a driverless forklift is ideal.

Why use MESH Automation for your AMR project?

AMR projects are typically complicated. MESH’s project management skills, along with their technical expertise in automation, machine control, and high-level software systems, make them an ideal partner to help you with your AMR project.