MESH Automated Resistance Welding Systems

Resistance welding is one of the most common joining methods used in today’s manufacturing environment. Resistance welding often produces strong and clean joints, free from spatter, and is often seen as a more reliable process to use on thinner material compared with arc welding. Additionally, resistance welding does not result in penetrations in the base material like riveting, which is of major benefit to items like electrical cabinets or tanks that are required to be leak-proof. Lastly, the process is very cost-effective for manufacturers, having almost no consumables other than the electrodes.

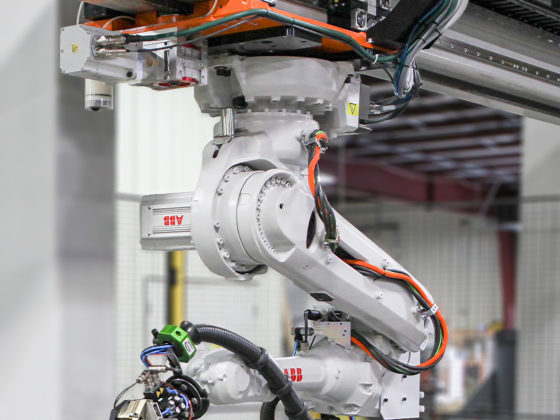

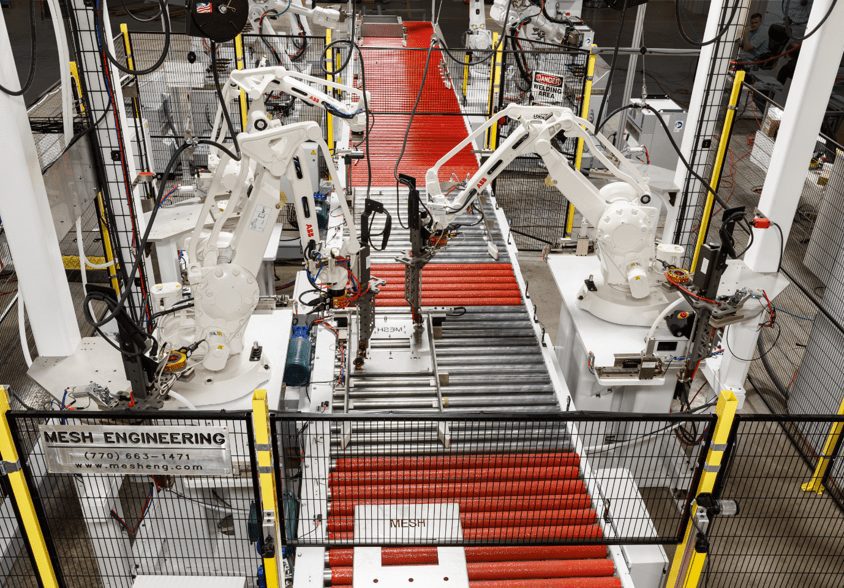

MESH Automation, Inc. often incorporates resistance welding in with other manufacturing solutions such as capacitive discharge or drawn arc stud welding machines. MESH also produces standalone automation solutions for resistance welding, such as flexible robotic spot welding, robotic resistance welding, robotic projection welding, or dedicated resistance welding machines.

MESH Solutions for Automated Resistance Welding

MESH has the expertise to provide flexible resistance welding solutions for your product. Whether this includes spot welding, seam welding, projection welding, or a combination of processes. MESH’s solutions can include robotic or dedicated automation, flexible, or automated fixturing, and a wide variety of power sources and guns.

MESH can incorporate machine vision on any solution to find edges or features. Weld quality monitoring can also be incorporated, and MESH can produce solutions that can weld a variety of thickness on the fly. Automatic loading of difficult raw materials to be welded, such as hinges, nuts, studs or brackets is also possible.

If you want to automate the resistance welding of your product, let MESH solve your resistance welding needs while increasing your productivity and quality.