MESH AUTOMATED RIVETING SOLUTIONS

The use of rivet nuts (rivnuts) and rivets are a time tested and proven joining method. With the increased use of high-strength low-alloy steel and aluminum being used in frames to decrease the weight of components, rivnuts and rivets have been becoming the preferred method of attaching components and panels.

Automating this process using robots or hard automation is a value-added proposition that MESH can help with. MESH’s solutions have been used by a variety of fortune 500 customers. Automation is the future for most manufacturing businesses and the only way to survive in today’s markets. It allows for higher and more consistent production, higher quality parts and allows companies to avoid the pitfalls with employee turnover.

MESH is an expert in automating rivnut and rivet processes. MESH has solutions for both lower volume, high mix production and high volume, low mix production. MESH has proven methods of quick tool changes and offers both pre-engineered and custom solutions to help customers solve their complex production needs.

MESH Solutions for Riveting

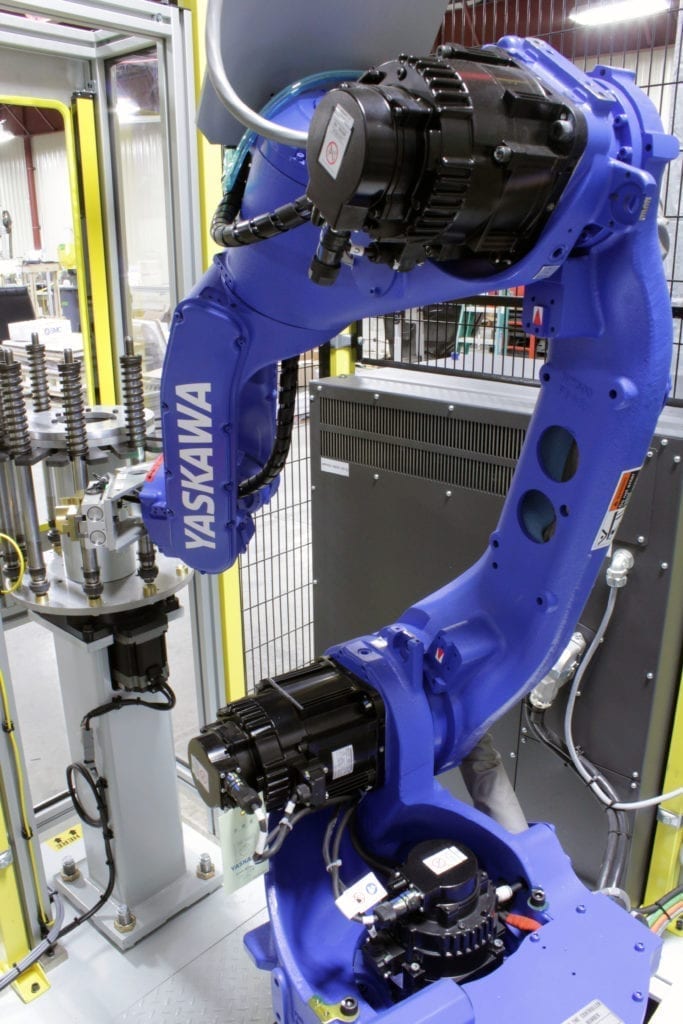

MESH can provide solutions for a wide variety of part sizes, incoming part variability, materials, production requirements and quality requirements. MESH can install rivets/rivnuts on a variety of planes (even curved parts) and have developed vision systems and programming to overcome warpage on welded frames. MESH works with a variety of robots, rivet guns, vision, and sensing products and rivet/ rivnut suppliers that allow us to handle even the most complex project.

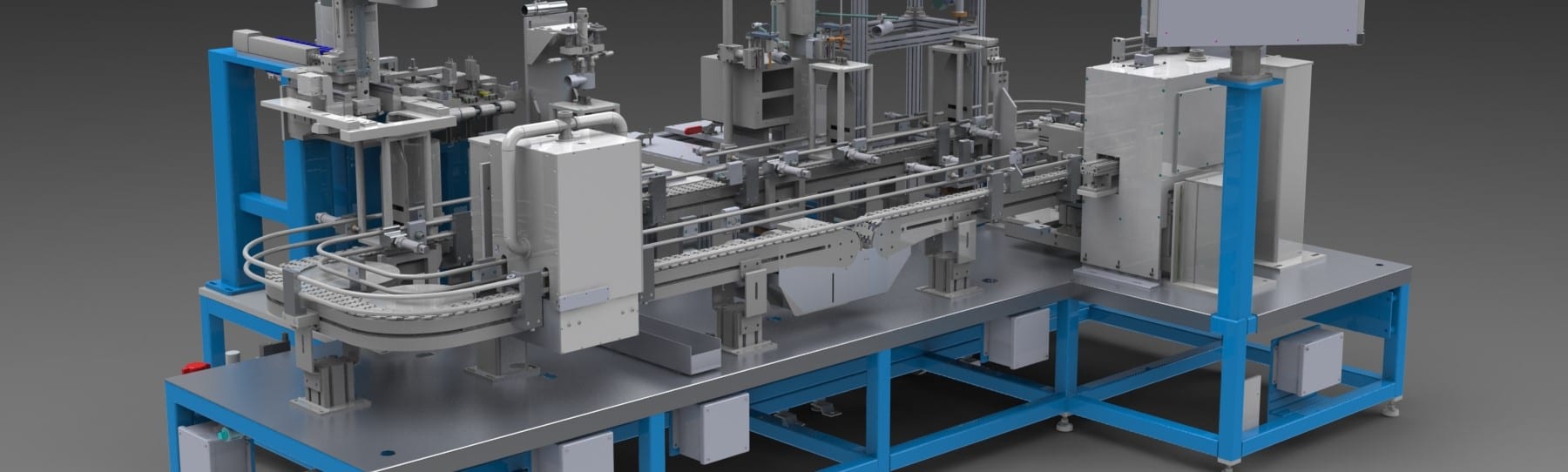

MESH is your one-stop automation firm for everything from just basic riveting/rivnutting cells ready for integration to fully “turnkey” solutions. Many of our solutions are also modular and are easy to move inside your factory.

MESH Automation Solutions

Whether you are looking for a simple standalone solution for inserting rivnuts/ rivets or a fully customized production line with rivnutting/riveting, MESH has the experience and expertise to solve joining related issues. MESH will do this in the most practical way without sacrificing quality or production.

Our robotic joining systems focus on innovated designs, and where available, utilize pre-engineered solutions to save cost and maximize reliability and the value of the system. We factor in aspects like the quantity of rivets/rivnuts, current quality issues, part size, base material and the cost of human labor to develop an automation solution that will get your company a great ROI.