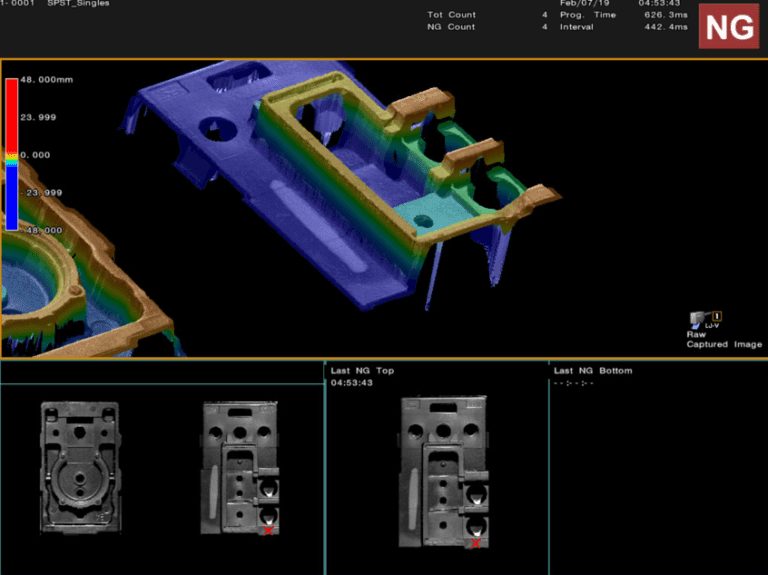

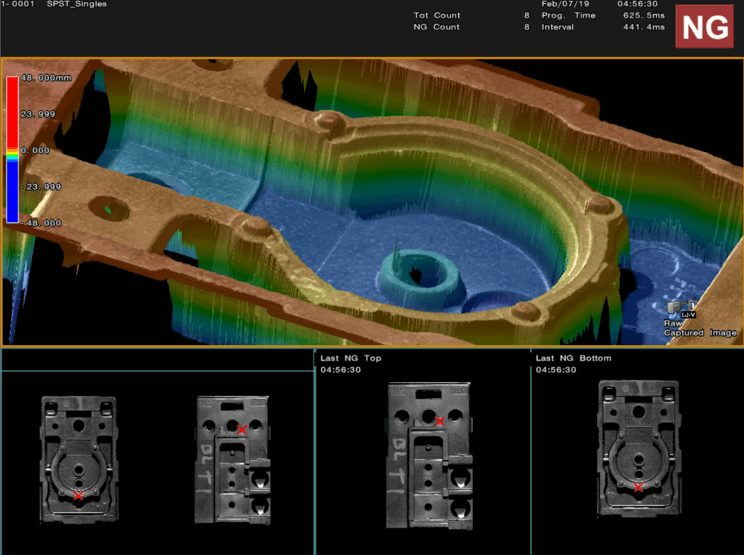

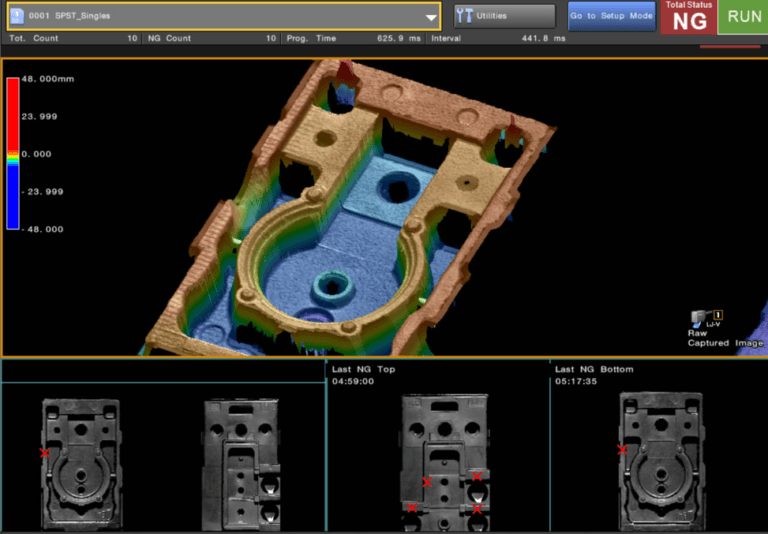

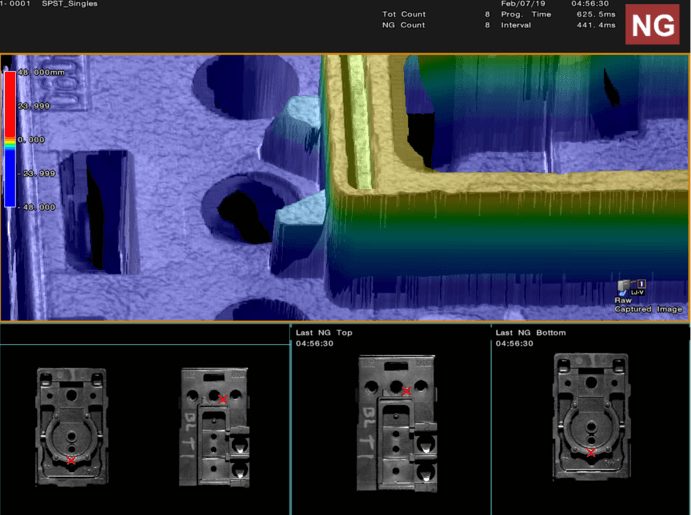

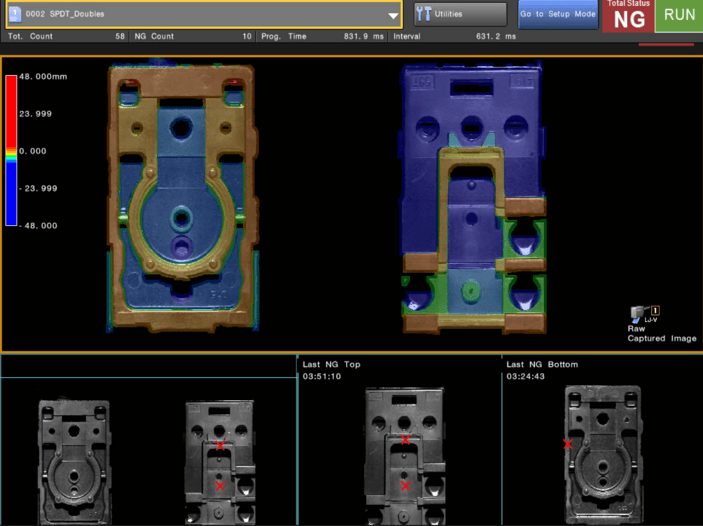

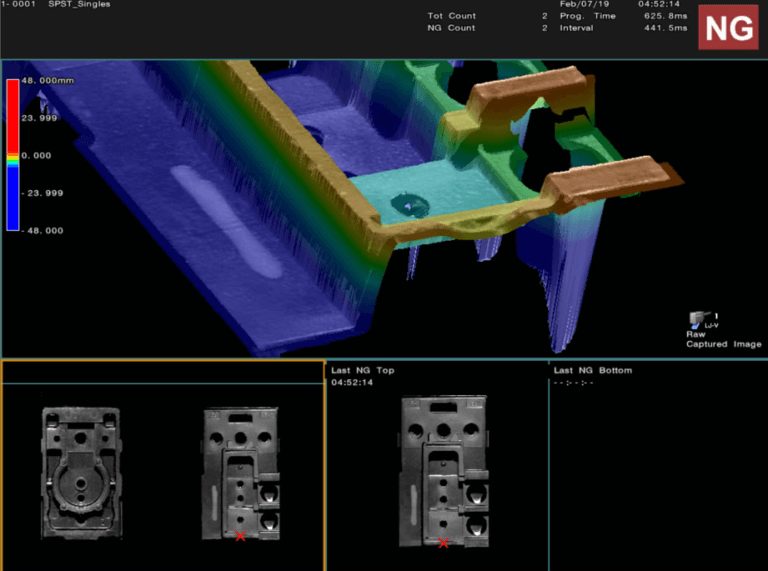

3D Vision of Injection Molded Part

3D Vision of Injection Molded Part

Project Details

Problem Statement; Customer required an automated machine that could inspect plastic injection molded parts for critical dimension and physical defect prior to assembly. Cycle rate required was two seconds per part. Rejects are quarantined into a locked bin with verification. Vision inspection is performed using two Keyence LJV- 7200 lasers mounted so their scan range can capture the entire top and bottom of the part. Vision performance criteria are as per below;

- Broken terminals walls

- Chipped surfaces

- Broken or missing plastic protrusion

- Feature height

- Blocked holes from flashing

Automation Equipment

- Keyence LJV-7200 3d laser

- Linear conveyorized track with traffic control

- Lockable reject bin with Poke Yoke features.

- AB PLC and HMI control cabinet.

Machine Performance

- Capacity Requirement: <2 seconds / piece

- Part types - two

- Poke Yoke features: Locked reject drawer w sensor detection

- Expected Utilization Rate: 24 hours / 7 days at 85% availability