Automotive Heat Shield Assembly

Automotive tier 1 suppliers are under constant pressure to reduce manufacturing costs and deliver the highest quality while providing a safe working environment. Quality and consistency of their product are monitored and penalties for deviating from specifications or delivering late are very high. Due to being constantly monitored by their customers and the resultant pressure they are arguably one of the highest users of robotic and other technical automation. In addition, their staff is highly skilled and technical minded.

Taking selective human elements out of the manufacturing process is a proven way to advance their agenda and become more competitive.

However, technology can typically be integrated more than one way and some ways are better than others. Equipment cost is not always the best indicator of the best value. MESH believes that a well thought out process that is collaborative in nature and a thorough technical review of the component used and raw material variability is critical to achieving a successful automation effort.

In this case study the customer required an automated machine that could feed automotive heat shields (five types), rivet two angle brackets, insert and press three fastener/washer/bushing stacks and offload a finished product. To meet the labor input targets the requirements were for the machine to be manned by one operator per shift, achieve an 85% OEE and to meet cycle rate requirements of 18 seconds.

After a thorough process review with the customer and a good understanding of the raw material variability MESH designed, and built one machine that accomplished these tasks.

- Three Bowl Feeders For Fasteners, bushings, Flat Washers, and Spring Washers.

- One Epson G3 350 Scara Robot with vision guidance For Assy of Fastener Stack With Special End of Arm Tool

- Rockwell CompactLogix Controller with PanelView Plus 6, 700 Color, Touch Screen

- Special Indexing Conveyor For Feeding Fastener Stack Into Presses.

- Quantity Three MESH Designed Auto feed Presses For Press Fit of Fastener Stack Into The Heat Shield. Three For Cycle Rate Purposes.

- Two Bowl Feeders for Angle Bracket and rivets

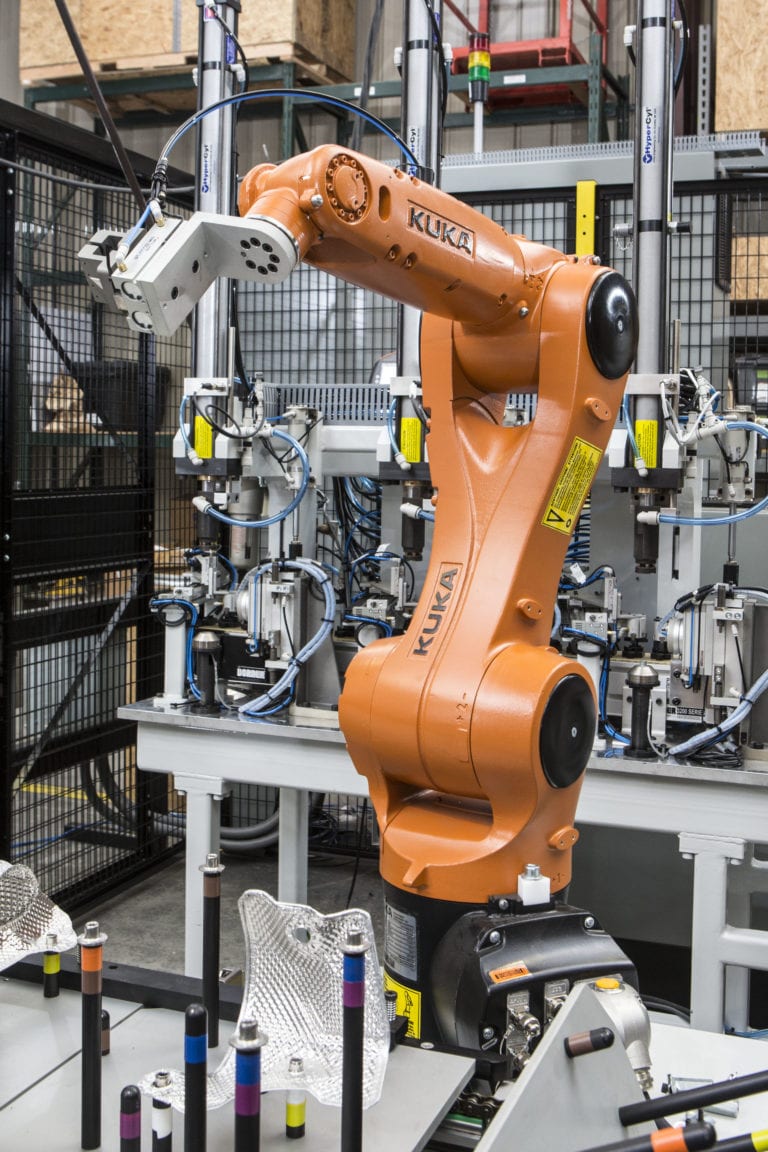

- Two Kuka KR 6 R900 robots for Pick, Place and Position

- Dorner infeed and outfeed index conveyors with special quickchange tooling

- Two Keyence vision cameras for part inspection

- Two MESH designed press/riveter stations

- Capacity Requirement: 18 seconds / piece

- Expected Utilization Rate: 24 hours / 7 days

- Equipment Availability: > 85%

- Pushbutton changeover except for product specific tooling. Tooling changeover to take 15 minutes or less