Inline Pharmaceutical Label Inspection

MESH recently engaged in a project for the inline vision inspection of labels for a major pharmaceutical company. The customer wanted to increase throughput and maintain their quality standard.

The labels varied in size and material. Some of the labels had a clear plastic backing and some had a white paper backing. The location of the information to be verified was in different locations based on the product type as well. There were over 30 different label configurations that had to be handled by the system.

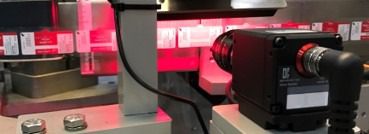

MESH developed a solution that utilized a single high-speed camera that was positioned inline with the labeler to inspect each label before it was applied to the vials. The system inspected each label to verify date code, lot number, and label number.

- Keyence 5 mega pixel camera system

- Keyence bar light

- Productivity: Due to the speed of the vision inspection system the customer was able to increase throughput.

- Quality: Reduced the amount of rejects caused by incorrect splicing of label reels and verified date, lot and label number information printed on labels.

- Uptime/ Maintenance: Due to the inspection being inline with the labels, it helped reduce the amount of vials that would normally be rejected if the wrong label or data was applied which helped this cell achieve >90% OEE.

- Changeover Time: Pushbutton changeover resulted in minimal operator involvement