Palletizer for Rolled Roofing

Palletizer for Rolled Roofing Case Study

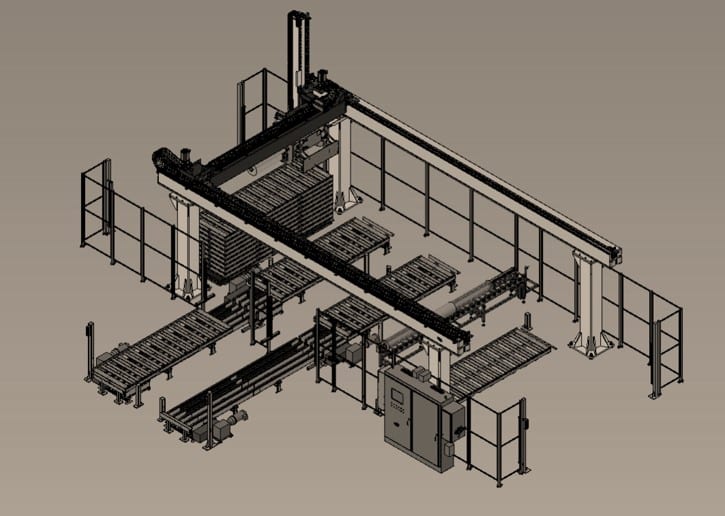

MESH designed, manufactured, integrated and started-up a custom engineered gantry style rolled roofing palletizing cell with the following specifications. The gantry was programmed to receive data from the customer’s system as to type of roll and pallet pattern. After receiving data the gantry would pick up an empty pallet, place it on one of two output conveyors and proceed to pick up a rolled roofing product from the infeed conveyor. After completion of the complete pallet, the system would convey the finished pallet out of the cell. Two finished goods pallets could be stacked at any one time due to the dual outfeeds.

- Pallet Weight: 1100lbs/3530lbs (min/max)

- Roll Weight: 80lbs/645lbs (min/max)

- Roll Diameter: 9.72”/14.27” (min/max)

- Roll Length: 40”/144” (min/max)

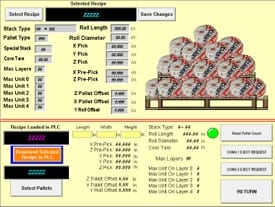

- Stacking Configurations: Eight total

- Output: 240 rolls per hour at 90% OEE

Automation Equipment

- Controller consisting of a Rockwell ControlLogix L71 PLC with PanelView Plus 6 1000 HMI. Dual Ethernet safety PLC.

- HMI consisting of a 19” Monitor and industrial computer running Wonderware

- Qty 4 medium and low inertia servo motors for gantry motion control

- MESH designed and built roll gripper

- One roll input herring bone roller conveyor, one empty pallet pickup station, two full pallet outfeed drag chain conveyor.