Robotic Grinding of Pipe Fittings

Foundries are typically automated with OEM equipment on the molding side but are typically labor intensive in the after mold processes. In addition, these labor-intensive activities are fraught with challenging safety, environmental, and ergonomic problems.

Technology developed by MESH for post-mold grinding of the parting lines and prefacing can help solve these problems.

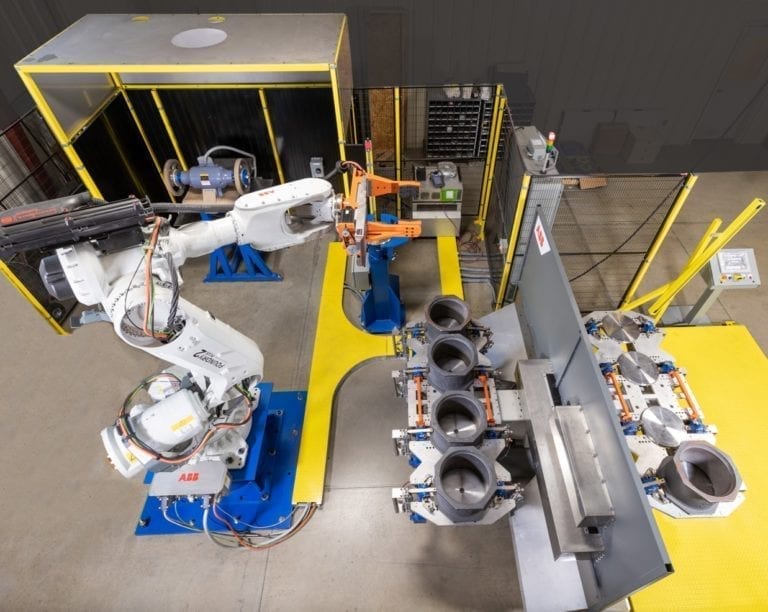

In this case study, the customer required a system that could relieve their operators from the manual tasks of grinding parting lines and prefacing their pipe fittings. The customer chose a semiautomated process where the loading of the pipe fittings was done by the operator with the assistance of a hoist, but the grinding, facing and offloading was done by a foundry duty robot, appropriate fixtures, regrip stations and end of arm tooling.

After a thorough process review with the customer and a good understanding of the finished goods requirements MESH designed, and built two systems that accomplished these tasks.

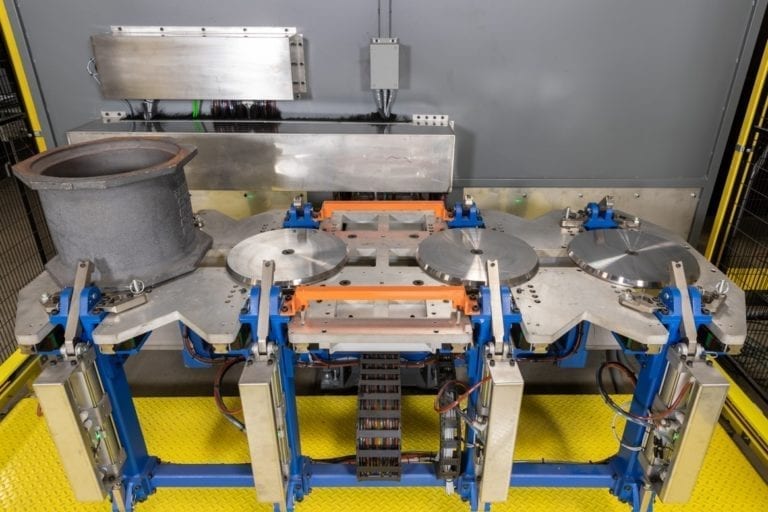

Fixture design was an important part of the system due to the large number of parts that the customer was processing and the short part runs. Pipe fittings from 4” through 16” of various types (90-degree elbows, 45-degree elbows, Tee’s, straight couplings, reducers) had to be accommodated.

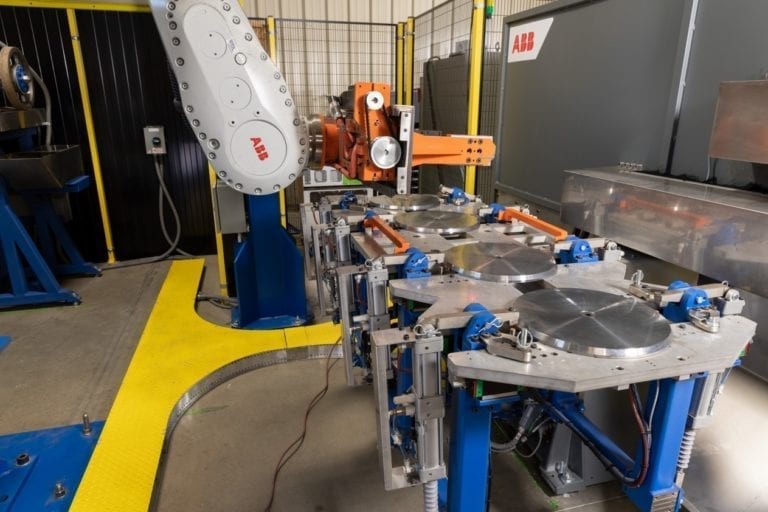

The fixture shown in the gallery below had automatic and verifiable clamping with only quick-change size discs being changed out.

The quick-change size discs where made from hardened 4140 for extra durability.

There were two fixtures mounted on a 360-degree servo positioner (controlled by the robot) with one side being exposed to the robot and the other side being in a safe zone (hard guarded from the robot and with light curtains) and available for the operator to load raw parts.

After grinding the robot would place the part on an outfeed conveyor (not shown).

- Part gripping was one of the most difficult technical challenges. To overcome these challenges MESH used a servo actuated (with torque monitoring) gripper with special jaws that used a combination of soft compensation and hardened jaw pads. Some pads were changed out depending on the product.

- The MESH designed grinding station used a diamond wheel for material removal mounted on an industrial grinder with horizontal compensation. This compensation regulated the pressure no matter where the robot was positioned on the part.

Due to the harsh environment, in addition to the reach, load inertia and tooling weight, MESH chose an ABB IRB6700 foundry duty robot with SafeMove.

Typical of robotic machine tending applications a regrip station was needed on some parts (like Tee’s.). The pictures in the gallery below shows the MESH designed regrip station.