Robotic Lathe and Press Tending

Robotic Lathe and Press Tending Case Study

Project Details

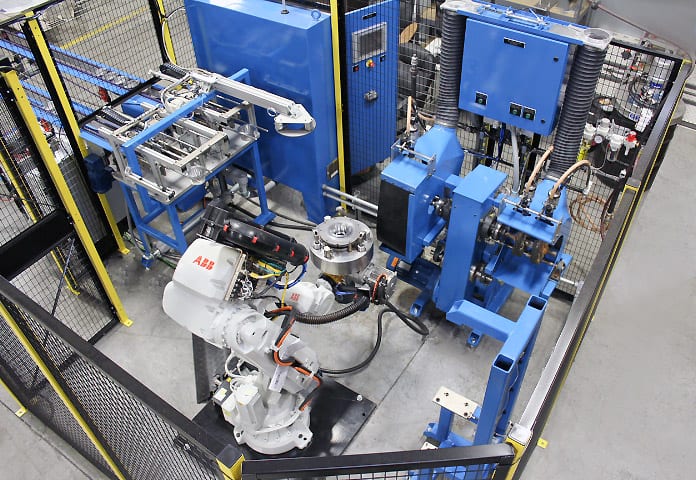

- MESH designed, manufactured, integrated and started-up five robotic tending cells for the fabrication and polishing of Galvanized Aluminum reflector domes.

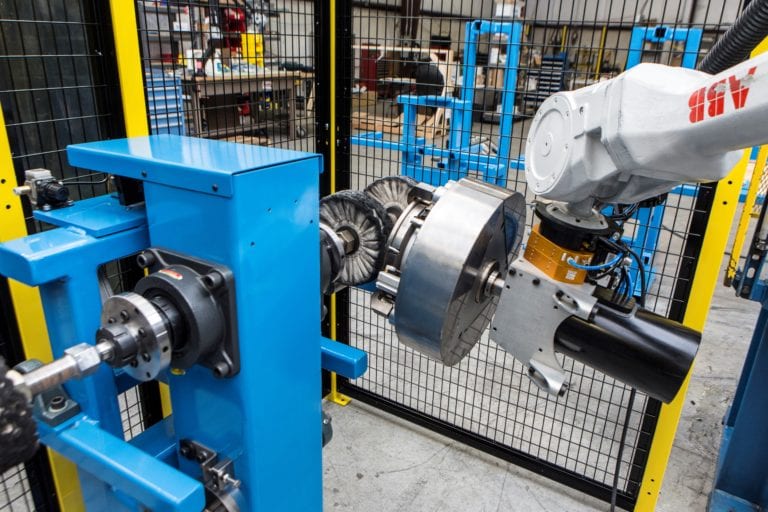

- Material flow started with a flat sheet of AL which was then punched, formed and polished. The ABB IRB4600 robot used a MESH designed dual jaw end of arm tool to pick, place and tend the punch press. Included in this sequence was a punch lubrication step.

- After punching the flat sheet of AL the robot picked the part out of the press and loaded the forming lathe where the dome was formed into it’s proper shape. Forming lubrication was applied by the robot prior to forming.

- After forming the robot selected another end of arm tool through the use of an ATI tool changer.

- After pickup the AL dome was presented to a MESH designed pressure compensated buffing station with proprietary spray buffing compound application system designed by MESH.

- A custom rotating end of arm tool designed and built by MESH was used to pick, hold and spin the AL dome while buffing was occurring.

- The robot would run a custom buffing routine for the inside of the dome and then present the dome flanges to another dual wheel buffing wheel for final work. Pressure compensation and buffing wheel diameter changes where automatic and consistent.

- After completion of the part the robot would place the dome on an exit conveyor.

Final Project Outcome

- Project was successfully implemented at the customer’s facility with a ROI of under 2.5 years.

- ROI drivers were production volume increase, ergonomic improvements, other safety improvements and labor savings.

- No loss or degradation of finished goods quality.

- Improved customer raw material sourcing, maintenance procedures were forced onto the management team by automation resulting in better plant management for the entire factory.

- Customer’s first robotic automation project at this facility resulted in improved technical skills and training curriculum for staff. This upgrade in skills has contributed to improvement in other areas of the facility and worker satisfaction.