Robotic Stud Welding

Robotic Stud Welding Cell Case Study

Project Details

- MESH designed, manufactured, integrated and started-up a custom engineered robotic stud welding cell for welding both standard capacitive discharge studs and collar studs.

- Cell was used to weld studs into electrical enclosures. Weld quality and stud accuracy was critical.

- Cell was part of a production line and needed to weld 5 to 9 studs in under 30 seconds.

- Automatic servo fixturing was utilized for automatic changeover between parts.

Automation Equipment

- Custom control system with an Allen Bradley Control Logix PLC

- Four customized HBS KAH412 Automatic stud guns

- One customized HBS C 08

- ATI automatic tool changers

- Two HBS VBZ Bowl feeders and four custom bowl feeders

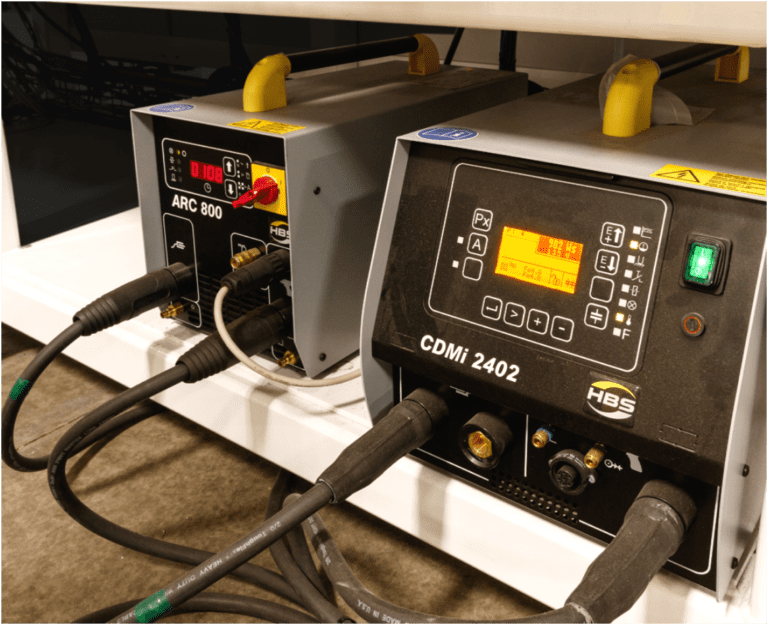

- One HBS CDMi2402 and two HBS ARC 800 power supplies

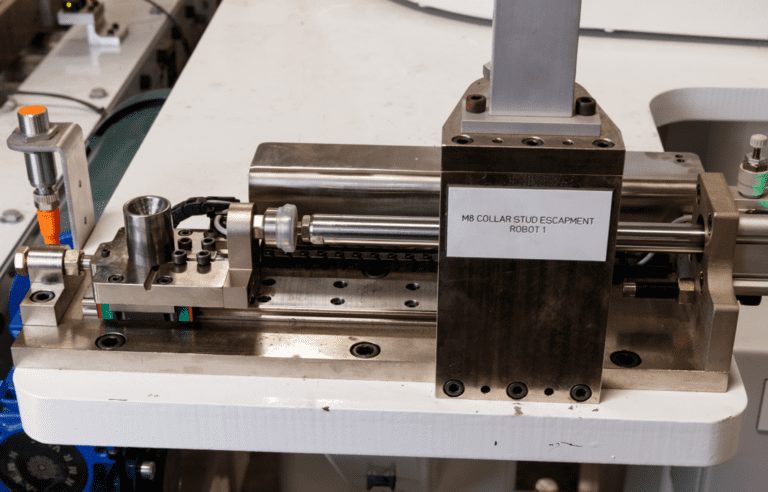

- Customized escapements for stud picking

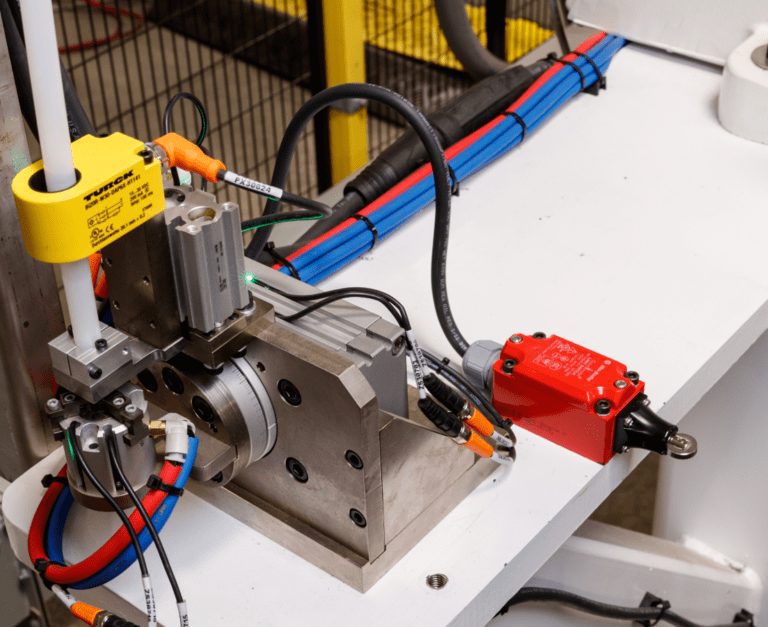

Fixturing

- Custom engineered servo fixturing.

- Fixture featured multiple grounding clamps to evenly distribute grounding spots.

- Fluoroclad SDFC was used on parts where spatter could stick. Additionally hardened tooling was used for grounding pads.

Final Project Outcome

- Productivity: Cell met all cycle time requirements, significantly reduced WIP in the factory and allow the customer to go to order based manufacturing.

- Quality: Stud were welded to within 0.008”. Additionally, poorly welded stud issues were eliminated.

- Uptime/ Maintenance: The cell achieved an OEE of 91%. Additionally, scheduled PM took considerably less time than required.

- Changeover Time: Instantly and 100% automatic

- Other: MESH installed a remote access system so MESH can support this customer without a visit to their factory.