MACTEND

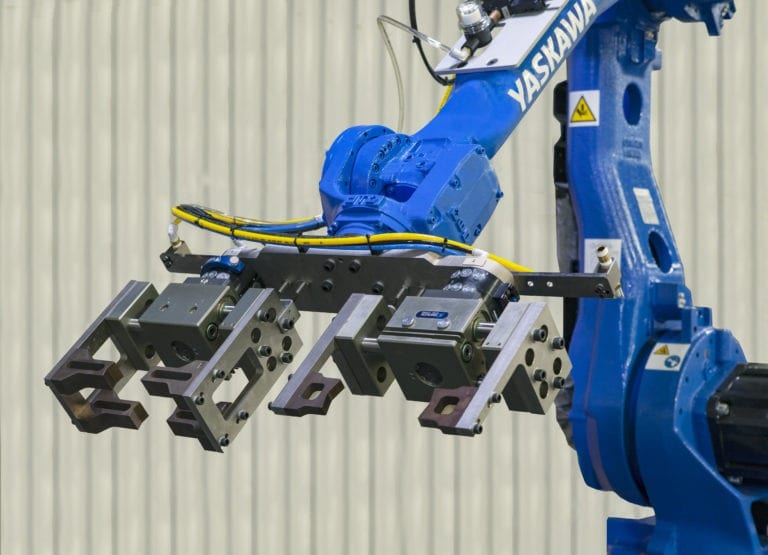

The MACTend is a professional grade skid-mounted tending cell designed for material handling and machine tending of small and medium-sized parts where process flexibility is paramount. The cell utilizes pre-selected components and “Bolt-On” process modules that can be configured in a manner best for loading and finishing your part.

The MACTend’s features, including being industry 4.0 ready, make for a great value with quicker deliveries and higher reliability. The solid build, fully enclosed, professionally finished cell will provide a long productive life and excellent return on investment.