MESH Automation Depalletizing Systems

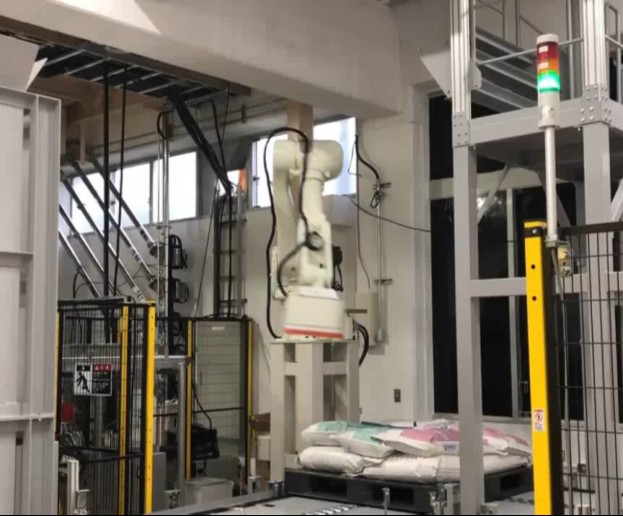

Better use of labor is driving robotic innovation into new territories. This need coupled with new technologies such as artificial intelligence (AI) and 3d vision sensors have brought robotic depalletizing from a fringe solution to mainstream.

At MESH we have leveraged our robotic system expertise and have partnered with AI software and sensor suppliers to offer our customers robotic depalletizing solutions in their many forms. Bag depalletizing for raw material feeding or single SKU depalletizing at a return center or full layer/decanting depalletizing as a feed system for a rainbow pallet or mixed case pallet are all in our solution pack plus more.

Choosing the Correct Depalletizing Solution

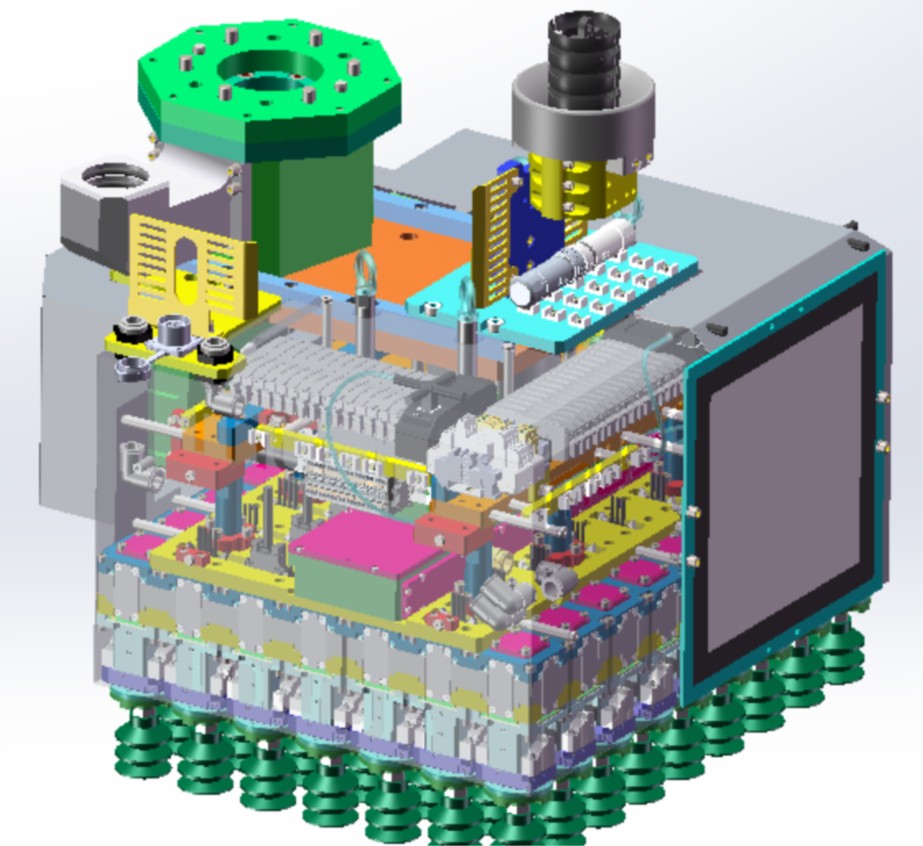

Mixed SKU Depalletizing – Mixed SKU depalletizing applications typically require removing one or more cases at a time and placing them on a conveyor for further processing. A mixed SKU pallet of boxes can now be depalletized efficiently with the new AI driven sensors/software giving direct control over the six axis robot and EOAT (end of arm tool). The sensors can be robot mounted or fixed mounted. The EOAT is also very complex with many zones, vision sensor(s) and load cell(s) for weight verifications reasons.

Typical applications –

- Return Centers Order fulfillment

- LTL or UPS/FedEx

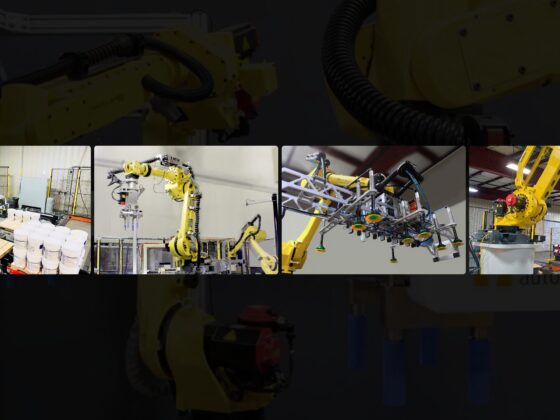

Single SKU Depalletizing – Single SKU depalletizing typically requires removing multiple boxes with each pick and placing on a conveyor or another order pallet. A Single SKU pallet of boxes is depalletized using more established technology that MESH has developed using four or six axis robots, simple zoned end of arm tooling and traditional sensors. The sensors can be robot mounted or fixed mounted. We have also combined depalletizing with palletizing all in one process (link to MACPal OF).

Typical applications –

- Recipe Processes

- Order fulfillment LTL to multiple stores

- Rainbow pallet

Doner Pallet Systems – Robotic depalletizing systems are typically deployed with “doner” pallet handling systems either through traditional conveyor, transfer carts or via AGV or AMR. These systems typically include empty pallet stackers by MESH to consolidate pallets thus reducing forklift traffic and floor space.

Capabilities of a MESH Designed Depalletizing System:

- One Robotic depalletizer by MESH can handle up to four “doner” pallet locations serviced by an AMR or AGV. Similarly, the “doner” pallets can also be conveyed into a destackable position. Putting a robot on a rail will increase the doner pallet inventory within reach of the robot.

- Cases per minute speed is usually forefront of most specifications. It is best to consult with MESH sales and applications engineers to understand the productivity needs and options available. Robotic depalletizing systems can typically depalletize in the range of 450 – 900 cases per hour.

- Pallet stack height – Most modern depalletizing robots if configured correctly can destack “doner pallets” up to 108” tall.

- Pallet or stack envelope (length and width) – Most destacking configurations are designed to fit into a 48” x 40” envelope, but robots are very flexible and can easily accommodate most requirements within reason.

- Dunnage – MESH can accommodate and depalletize the most common dunnage requirements.

- Safety – MESH designs our robotic case depalletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

Depalletizing FAQ

Are the new sensor and AI technologies reliable? MESH has partnered with suppliers that have 100’s of systems in operation around the world. There are limits to this or any technology, but after evaluation MESH will point out any areas of concern.

Can the system handle taped or glued boxes? Yes, our system can handle a taped or glued box top and bottom. Open top cases can also be handled depending on the stacking arrangement.

How much space does a typical system take up? MESH has pre-engineered systems that are as small as 60” x 144”.