High-Speed, Automated Pail Palletizing Systems by MESH

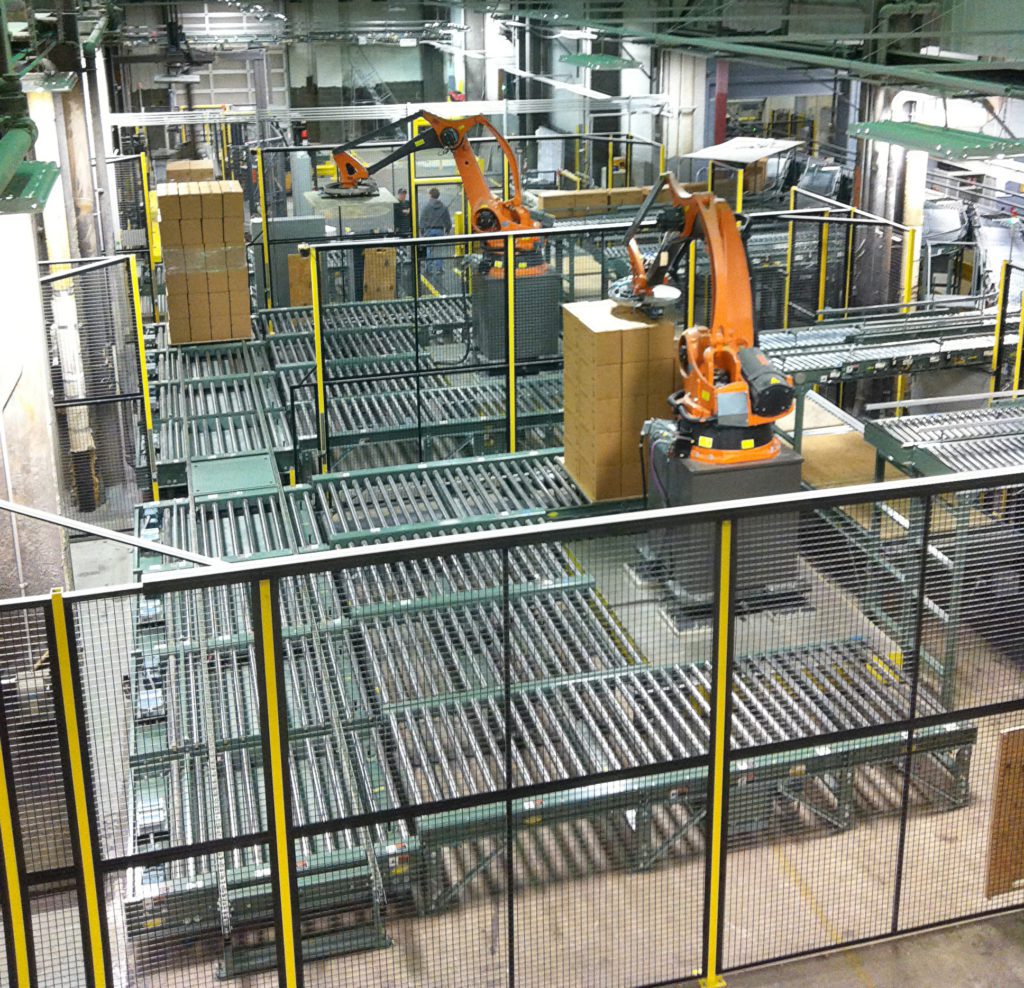

Pail or bucket handling is an area with plenty of automation opportunities. Pail orientation (label and handle position), pail labeling, robotic pail stacking and or robotic pail palletizing plus final banding or stretch wrapping with autonomous warehouse transport (through use of AMR/AGV) are all areas that have a great return on your automation investment.

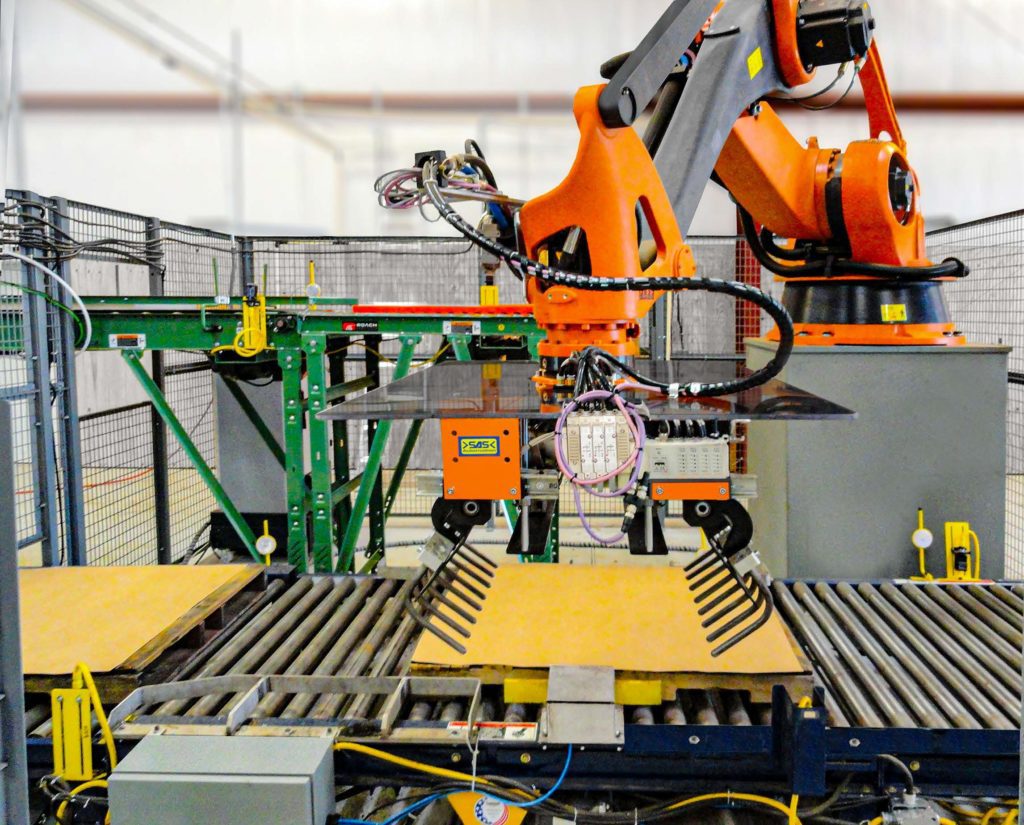

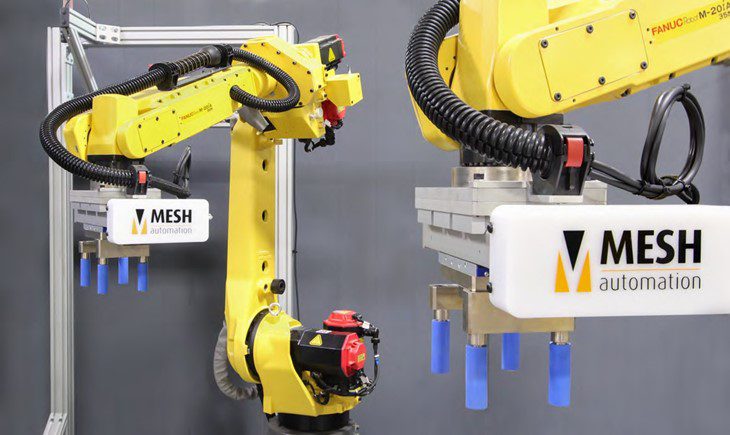

MESH Automation has proven experience and equipment offerings for all of the above automation opportunities. MESH uses robots by ABB, FANUC, and Yaskawa as the primary tool for stacking and palletizing pails. Our custom-designed end–of–arm tool works great for securing and precision picking and placing entire rows of pails to maximize the cycle rate.

Using a robotic pail palletizer by MESH Automation offers the greatest flexibility with up to four different SKUs that can be processed individually by one robot cell.

Without proper pail positioning, the entire automation cell can be compromised. Many pail stacking configurations require proper handle position, label position, and precision stacking for proper nesting. MESH has designed and developed our pail orientation system to properly get pails in the right position before the robot picks and secures the pails for stacking. This system is proven, rugged, and can be made with partial or full stainless steel materials.

Automated pallet handling using a pallet dispenser, dunnage solutions for slip sheets, and trays plus pallet labeling are common requirements where MESH Automation can provide equipment solutions.

MESH is Your Robotic Pail Palletizer and Pail Palletizing Specialist

- Robotic pail palletizers can perform precise movements with control over acceleration to protect every type of product. Modular designs are scaled to suit product size and weight.

- Pail orientation equipment by MESH Automation can label your pail, orientate the label for a consistent look on the pallet, orientate the label with respect to the handle and pallet plus control the pail center distances for the desired stack and consistent nesting.

- Material handling systems from conveyors, lane diverters etc. to provide material handling to and from MESH’s Robotic pail palletizers are highly customizable and are integrated with the machine’s control to optimize speed and function. Stainless steel construction is available if specified. MESH builds their conveyors for control over design, warranty, and project schedule.

- Product flexibility – Robots that can palletize pails coming from up to four different production lines and robotically palletize individually on their own pallet.

- Product weight – Robots can lift over 300kg (660 lbs) if specified correctly. With MESH automation’s custom pail end-of-arm tool four pails weighing 75 lbs. each are no problem.

- Dunnage – With automatic pallet dispensers, slip sheet dispensers, tray formers, and the correct end effector MESH can accommodate most dunnage requirements.

Benefits of MESH Automation’s pail palletizer

MESH Automation Inc. specializes in designing and building engineered solutions for robotically palletizing pails and similar containers. Our experienced teams use our pre-engineered solutions and create customized solutions to meet the needs of our customers.

Some typical benefits of MESH Automation solutions include:

- Pail orientation systems offering a great return on investment by creating a precise pallet of finished goods that provides that professional look to enhance your brand and protect your product during transport and storage.

- Highly efficient systems that increase production rates, improve labor utilization, improve job conditions (better ergonomics, less forklift interaction…) reduce product waste and improve product and package quality.

- Flexible designs and specifications that cater to multiple product lines, future product modifications and changes, and altered pallet patterns with a customized footprint to optimize floor space.

- Safety – MESH designs our robotic pail palletizer to A3 standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia or Europe.

- Solutions to eliminate forklifts by using autonomous vehicles (link to AMR page) such as AMR’s (autonomous mobile robot) aka AGV (automated guided vehicle)

- Systems that can be integrated with planned or existing equipment such as filling equipment, lidders, labelers, stretch wrapper or conveyor systems.

- Use of long-lasting, top quality components that meet different industry specifications for durable and hygienic use.

- Turnkey project management including Installation of equipment, start-up and training.

Pail Palletizing FAQ

What are the advantages of a robotic pail palletizer over a mechanical or gantry palletizer?

Robotics are the ultimate flexible automation tool. They can easily be reprogrammed to make minor adjustments to improve your finished goods product. Additionally, changes to your pail design over time can be easily accommodated.

Robots are high-volume products that have been refined to provide extraordinary life with very little maintenance.

Why use MESH Automation for your pail automation project?

MESH Automation has vast experience in robotics and offers great flexible solutions for robotic pail palletizing. MESH provides turnkey solutions and controls the design, build, and commissioning in-house at our facility in Georgia.