Collaborative Robots by MESH Automation

Collaborative Robots or Cobots are relatively new to the industrial robotics sector. These latest generations of robots are designed from the ground up to have mechanical features and software that allows them, when properly applied, to work next to humans in a safe manner.

A modern Cobot does not have pinch points and has incorporated sensors to detect and quickly stop the robot at the point of a collision. The collision force is very small and deemed safe for humans. Additionally, the well-designed Collaborative robotic system has software that limits its speed to 1meter per second and control features to easily add on standard safety sensors such as light curtains, scanners, and safety mats.

A risk assessment on a Cobot system still needs to be done by a professional to assure that the total automation system has the appropriate features and design to operate safely.

Because of the speed and force limitations, Cobots have a limited reach and payload. However, there are many applications that are ideal and propel a Collaborative robotic system to be the best value over other automation systems.

Advantages of Collaborative Robotic systems and Cobots

Cobots are designed to work safely around humans therefore they typically have a smaller footprint than a comparable industrial robot with a safety fence/system. Integration of simple pick and place applications can be easier and thus less expensive due to the easy-to-use Cobot software. End-of-arm tools designed for cobots have plug-and-play features making them simple to integrate.

Collaborative Robotic System Applications

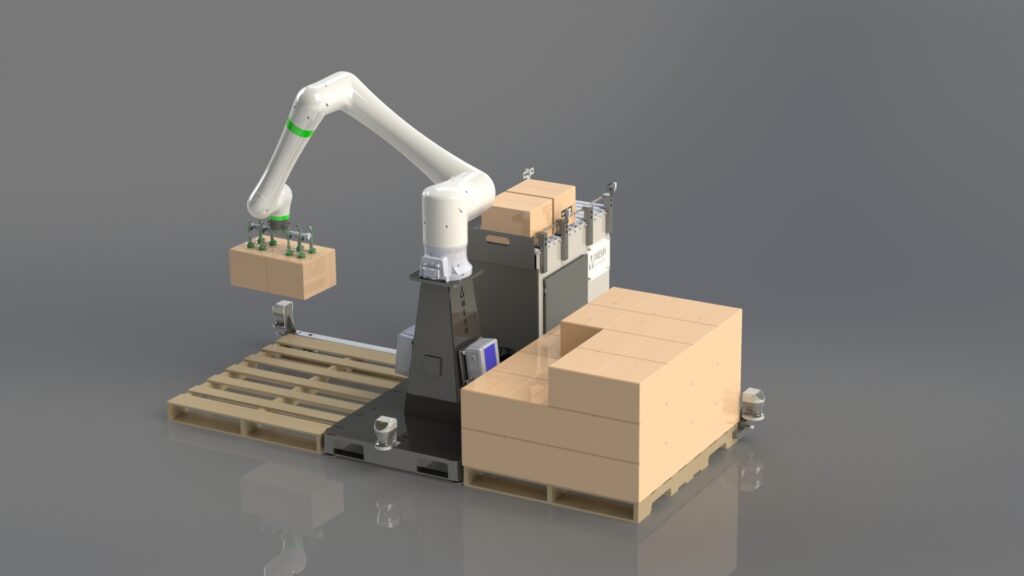

- COBOT PALLETIZER – The largest Cobots available have a payload of 25/30kg and reach around 1.8meters. This limits the Cobot palletizing system to a maximum stack height of around 80”. Payload is a limiter to around 35lbs after factoring at the end of arm tool(s) weight. The speed limit for a Cobot palletizer for most applications is around (4) round trips per minute. For example, if your product allows the Cobot to pick and place two products, due to weight, the Cobot Palletizer will stack eight products per minute. The Cobot Palletizer, by MESH Automation, has a very small footprint and an easy-to-use interface. Additionally MESH will build and integrate the proper product infeed system and pallet outfeed that you need. For the right fit, a Cobot palletizer has second to none value.

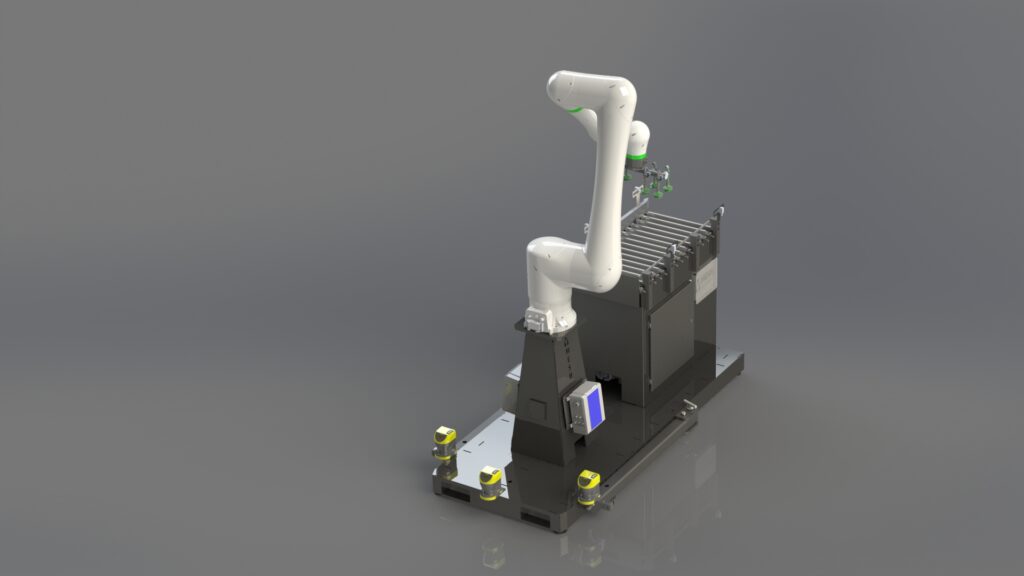

- COBOT MACHINE TENDING – Medium and large Cobots are ideal for a lot of machine tending systems. A Cobot machine tending system by MESH Automation is lightweight, easy to set up in front of one machine, and made portable for set up in front of different machines or removed for access reasons. Single or dual gripper systems can be employed based on a value to performance discussion. Raw material infeed and outfeed systems by MESH are ideal to customize your system.

Although the Cobot is safe by itself the machine that it is tending is typically not safe without guarding. MESH can design and integrate the right safety system as needed by the risk assessment.

Because the Cobot has speed limitations the ideal automation opportunity is one where the tended machine cycle is greater than 12 seconds.

- COBOT ASSEMBLY – All Cobots and their Cobot-ready end-of-arm tools are designed around picking and placing objects. As long as the end of arm tool or product is safe at cobot speeds they are good for assembly operations where humans are working nearby without guarding. MESH Automation has core competencies in many assembly operations. Our experts can design the right system and right robot for your application.

Cobot FAQ

What are the key differences between an Industrial (noncollaborative) robot and a cobot?

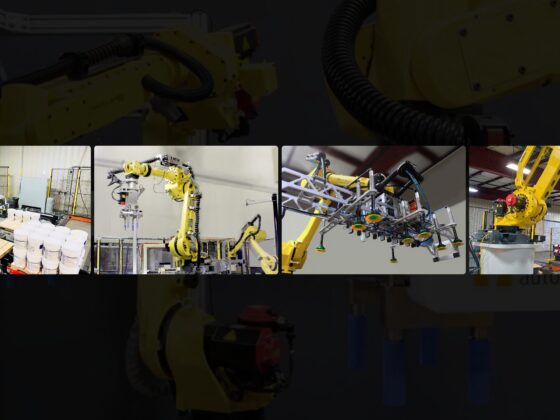

Industrial (noncollaborative) robots are designed to achieve maximum speed, payload, flexibility, and reach that is ideal for a specific application. The major brands of industrial robots typically have 50 or more models to choose from. Cobots are designed to work safely around humans and are thus limited in their reach, payload, and speed. If the application fits into the collaborative robot’s parameters, they are a good value, requiring little to no safety fencing and minimal floor space.

Are Cobots less expensive than Industrial (noncollaborative) robots?

The robot in most automation systems is just a part of the overall cost. When a Cobot is professionally specified and fits the application’s needs, the overall system can be a better value and price. The professionals at MESH can advise you about the pros and cons of each for your application.