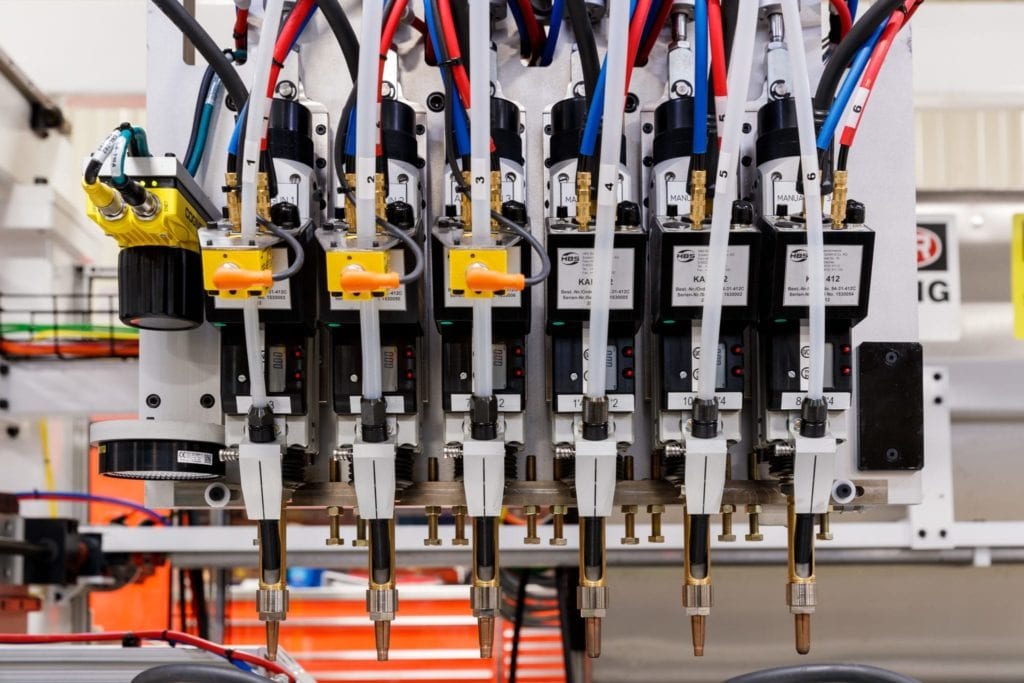

MESH Automated Stud Welding Systems

Stud welding is used to manufacture various things such as vending machines, kiosks, electrical panels, lighting, aircraft components, and heat exchangers. It is also used in special processes such as tagging large material billets with identification information and even securing insulation. MESH produces both robotic and gantry style automation machines for the industrial user who needs a durable and productive stud welding solution. Our solutions are designed to be operated 24/7/365 and produce reliable results for years.

MESH offers solutions that are not only highly accurate, reliable and productive but can be fully automatic, weld on multiple surfaces, automatically feed collar-type or difficult to feed studs, contain vision guidance, contain vision weld and spatter inspection and monitor weld quality.

MESH Solutions for Stud Welding

Using the stud welding process to produce parts brings many benefits, stud welding is cost-effective, parts can be made quickly, parts don’t need holes for the traditional bolt and nut fastening method and the weld is often stronger than the base material or the stud itself. Despite these benefits, stud welding does have challenges such as auto feeding studs that are traditionally considered not feedable, welding studs in hard to reach areas, welding studs with high placement accuracy, weld quality monitoring, reducing or eliminating back marking and adding flexibility to solutions to accommodate a large range of part sizes or geometries.

MESH has expertise in stud welding. MESH’s solutions are highly reliable, flexible and durable. MESH can also weld exotic materials.

MESH Automation Solutions

MESH can provide stud welding solutions that can:

- Auto feed collar-type studs or other typically non-auto fed studs

- Monitor weld quality

- Locate studs in relation to part features using vision

- Weld on curved, angled or vertical surfaces

- Weld extremely large or small parts

- Utilize shielding gas

- Work on a variety of material types like steel, stainless or aluminum, and Inconel.

- MESH can also produce solutions where the parts can be simply manually fed into the machine, up to completely automatic solutions for “lights-out” operations or high productivity.

Whether you need a solution to produce small parts at low or high production rates, extremely large parts or need a flexible solution for varying parts, MESH is your one-stop automation firm.