Automated Bag Palletizing System Utilizing Robots

Today’s, automated palletizing robots have unprecedented speeds, reach, accuracy and flexibility. Coupled with the latest in end-effector designs more options are available to bring the best value to your project.

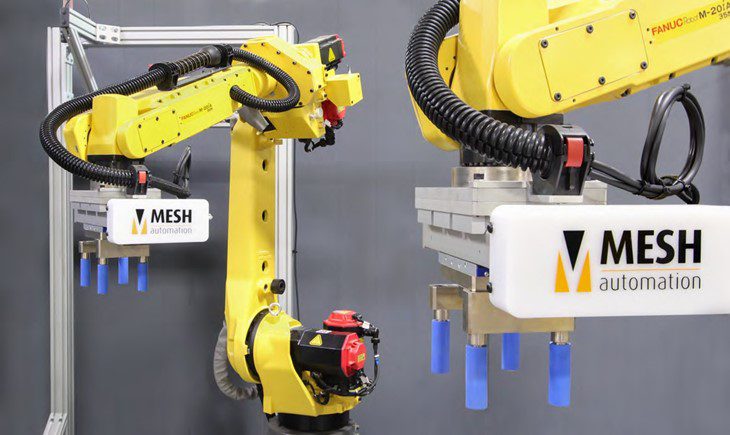

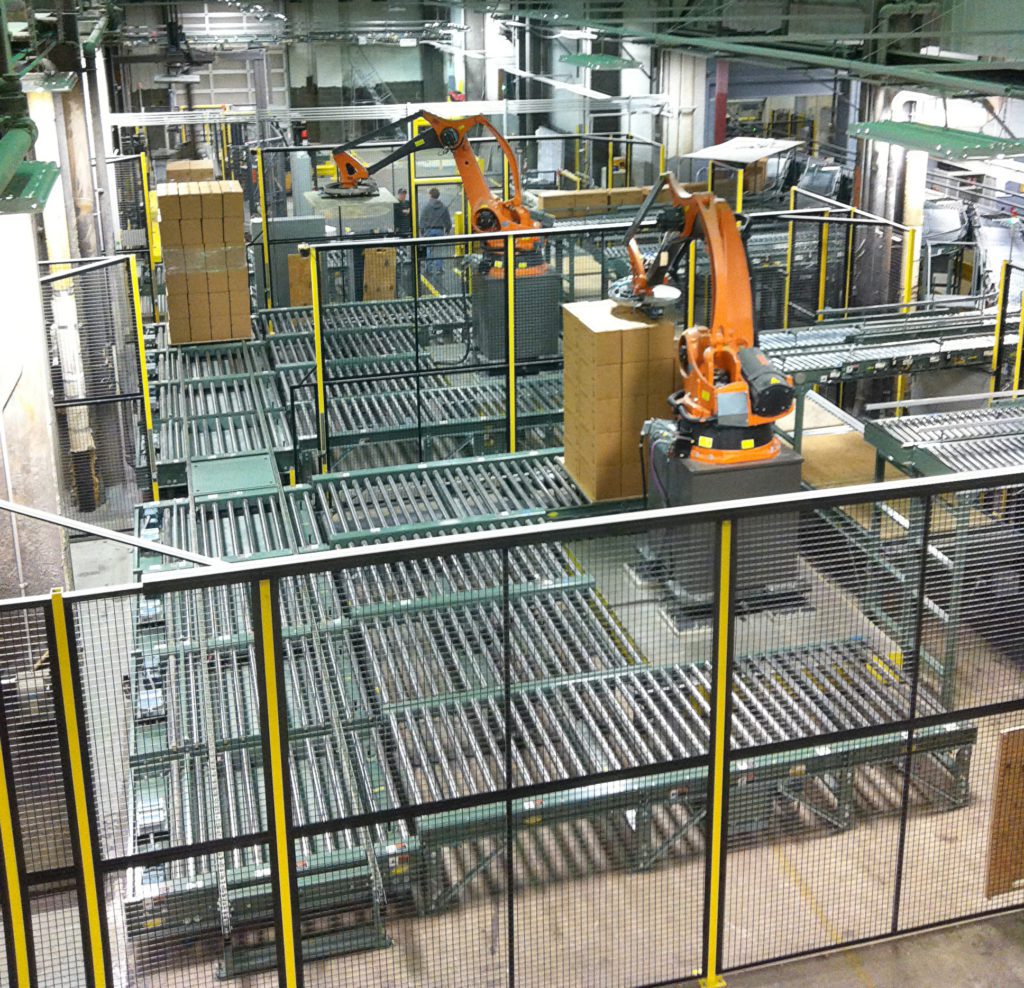

MESH Automation designs and manufactures robotic bag palletizers in a wide range of configurations. Our high-speed robotic bag palletizers, bag conditioning systems, pallet dispensers, slip sheet dispensers, material handling equipment, and our MAC control system work seamlessly together to bring the highest value to your production. MESH will integrate other built accessories such as stretch wrappers and labelers to complete your project turnkey.

Benefits of MESH-Designed Robotic Bag Handling Equipment

Experience matters in bag handling system design. MESH has vast experience in robotics to provide competitive robotic bag palletizing systems comprising the heart of the packaging end.

Automation is ideal for most bagging operations and can provide reliable and short returns on investment due to the repetitive nature of the tasks, ergonomic dangers to humans (weight and motion), dusty and dirty environments, forklift dangers, and sometimes seasonal labor availability issues.

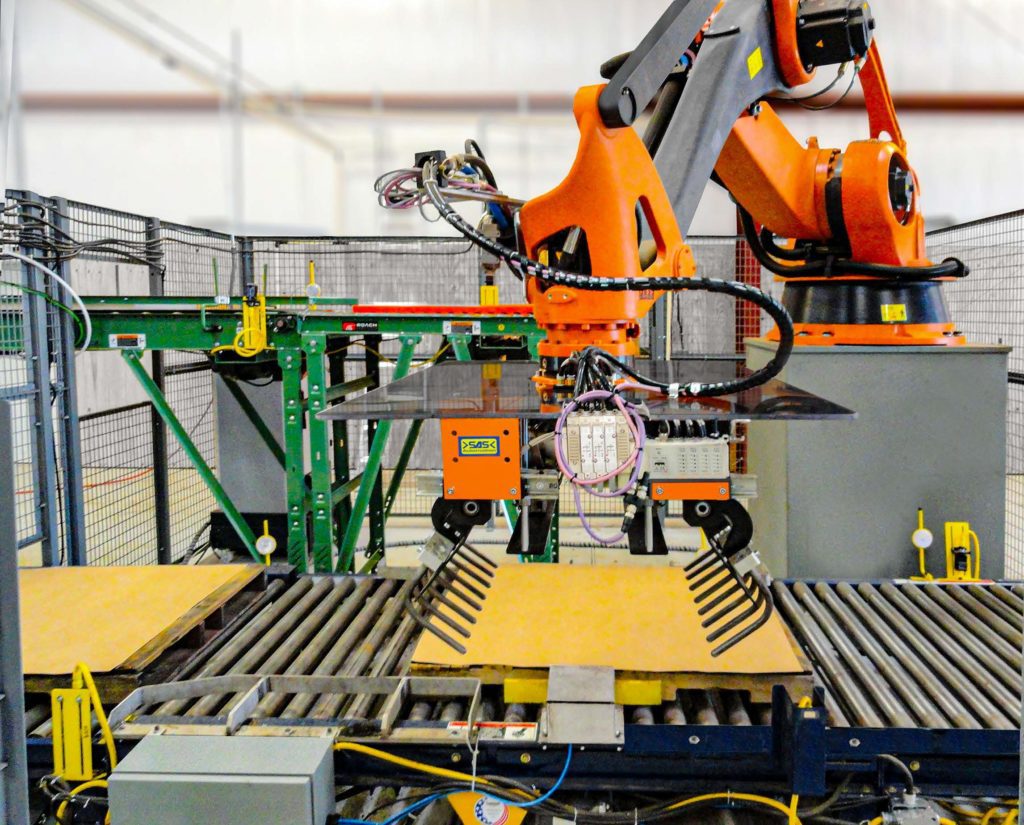

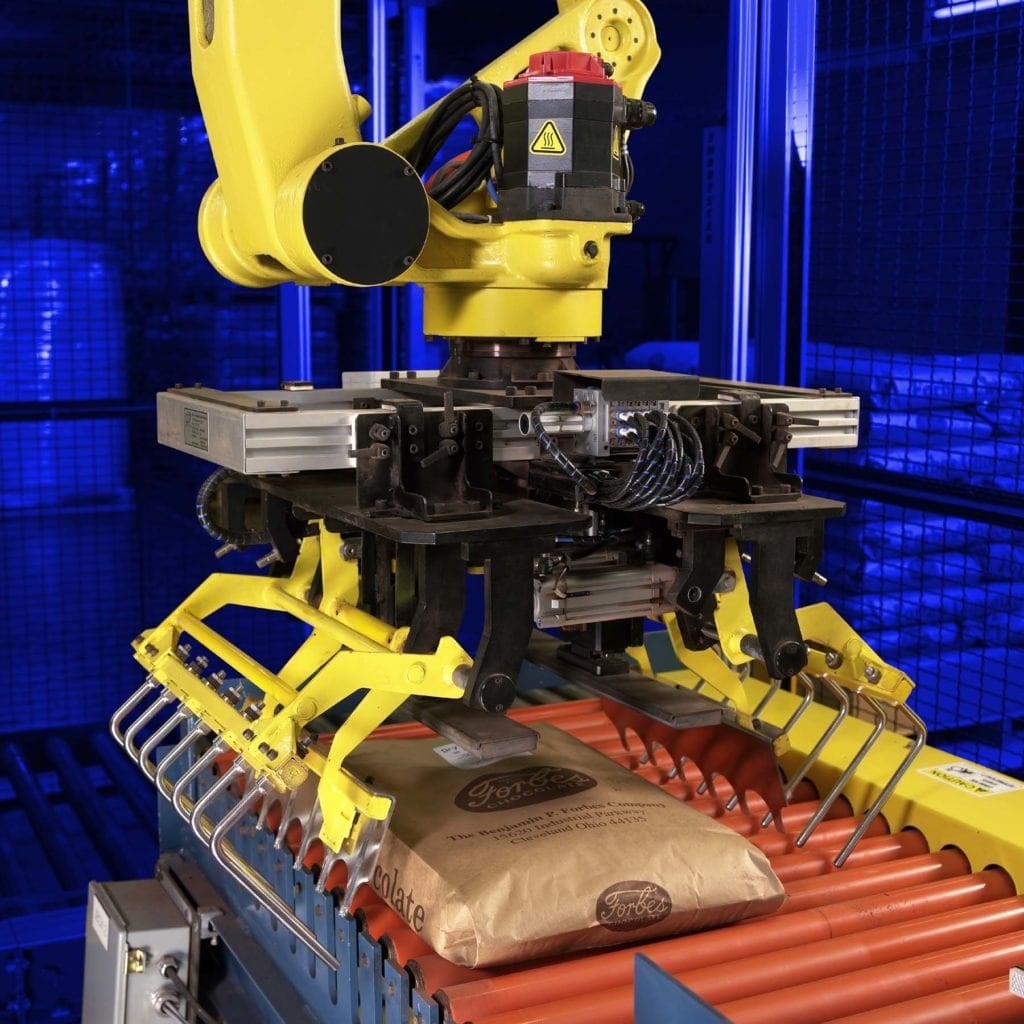

“Not all bags are the same” – MESH’s experience in a wide range of bag materials plus the highly varied physical characteristics of the contents make bag handling unique and challenging compared to corrugated boxes, sheets, or other more stable products. MESH has developed and used vacuum pickup, claw, and hybrid robot end effectors to accomplish what is needed to reliably pick up and place a bag or multiple bags. Additionally, bag conditioning and staging prior to robotic pickup make a difference. MESH has more than one solution depending on the product being packaged.

System design needs to be simple so maintenance is easy to understand. Operator functions to unjam or clean up the area need to be taken into consideration in addition to an intuitive operator interface or HMI. MESH has this experience and it shows in our equipment ruggedness and simplicity.

MESH Bag Palletizing Capabilities

- Bags per minute speed is usually forefront of most specifications. It is best to consult with MESH sales and applications engineers to understand the physical constraints of the product and options available. MESH has built robotic bag palletizers that range from 12 to 24 bags per minute.

- Pallet stack height – Most modern palletizing robots if configured correctly can stack up to 108” tall. However, stack height for bags is usually limited due to stability and weight.

- Pallet or stack envelope (length and width) – Most stacking configurations are designed to fit into a 48” x 40” envelope, but robots are very flexible and can easily accommodate most requirements within reason.

- Stacking quality or aesthetics – bag conditioning and method of bag pickup in addition to stack pattern dictate stack quality. The customer may have to modify their bag dimensions to optimize stack density with envelope constraints and stack stability/aesthetics. Stacking with side constraints is an available method to help with bulging stacks. The good news is a robotic application allows for quick and easy optimization.

- Corrosive environments – Many bagged products are corrosive in nature or food grade. MESH can offer solutions that meet those requirements.

- Dunnage – With automatic slip sheet dispensers and the correct end effector MESH can accommodate most slip sheet requirements. MESH can also provide systems for corner boards prior to stretch wrapping or stacking inside a sleeve.

- Safety – MESH designs our robotic bag palletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia or Europe.

Bag Palletizing FAQ

What are the key reasons companies choose automatic bag palletizing systems?

Labor issues are at the forefront of most automation decisions. Most bagging operation jobs are high speed, dirty, dangerous, and undesirable (hard to find workers). Human interaction with forklifts are accidents waiting to happen. Robots and other automation along the packaging line eliminate these labor issues forever. Additional benefits are improvements in stack quality and consistency.

What is a semi-automatic bag palletizer?

Semi-automatic bag palletizing systems use palletizing robots to automate about 80% of the process. Operators do the rest of the work, for instance, placing empty pallets with slip sheets on the floor close to the robot and doing the finished goods material handling.