MESH Automated 3D Vision Inspection Solutions

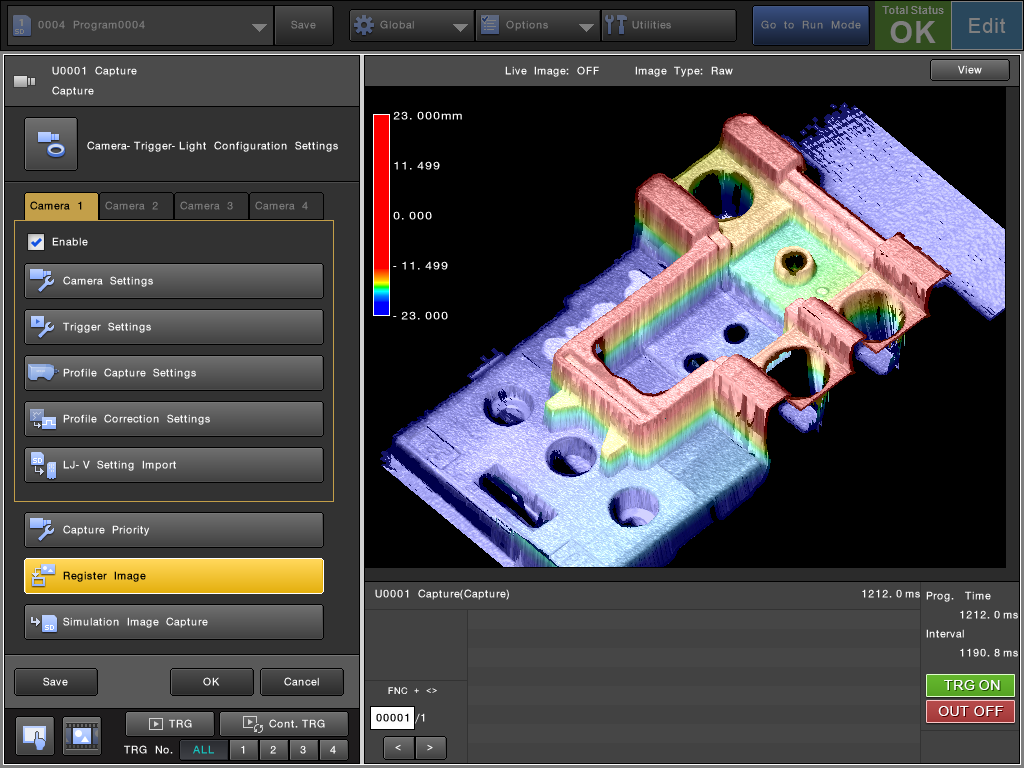

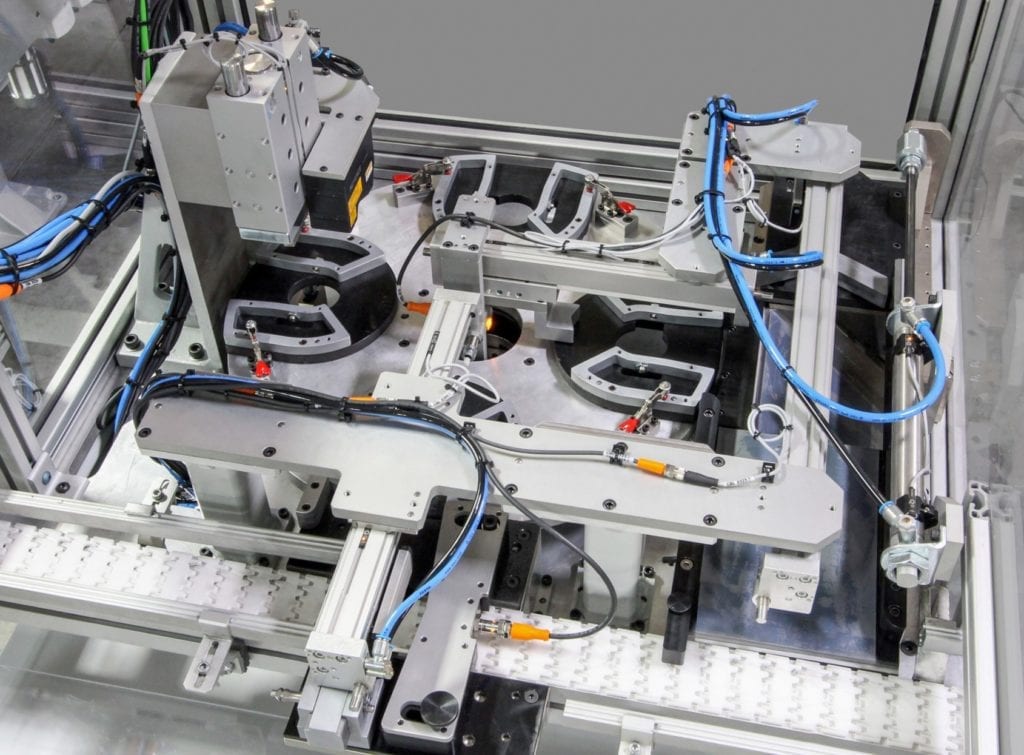

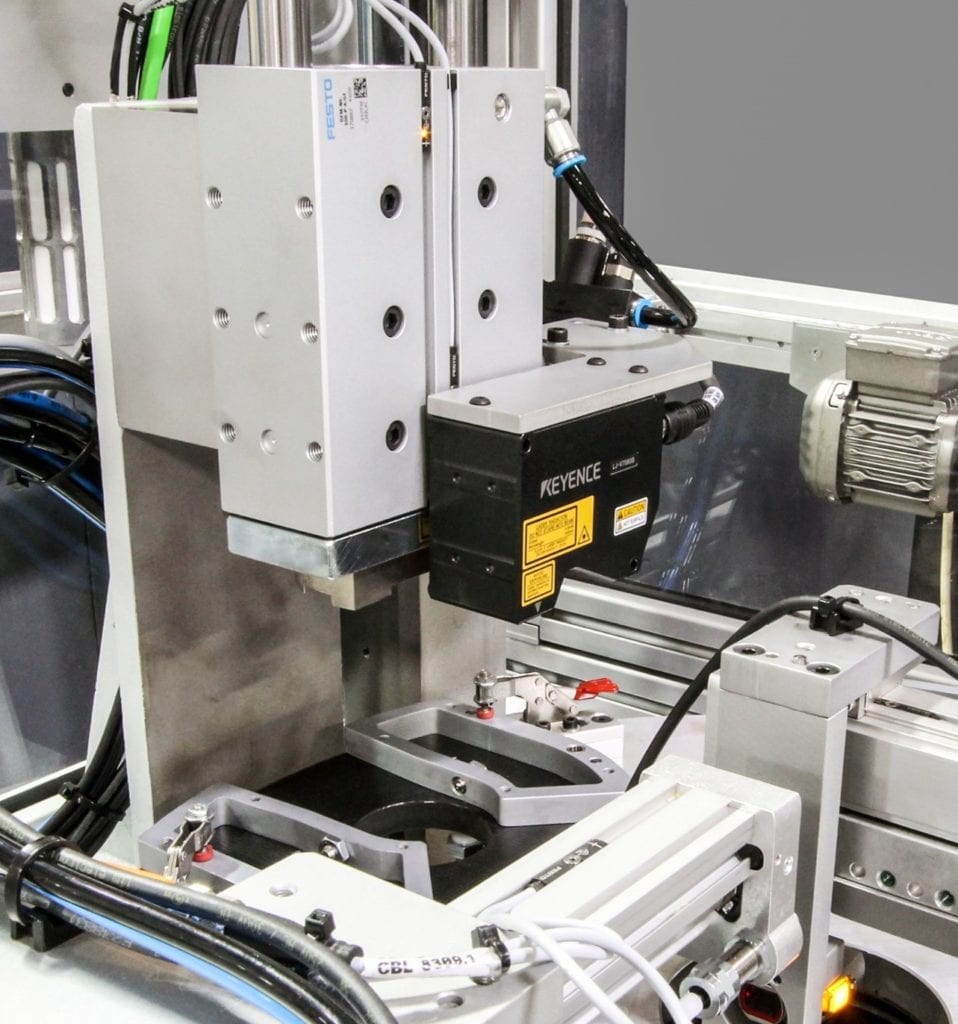

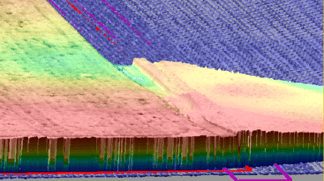

When it comes to test and inspection, both 2D and 3D vision systems may be used to help improve processes and productivity in manufacturing facilities. However, while 2D vision cameras are commonly used to identify defects, 3D systems have distinct advantages for complex parts and assemblies, identifying defects or features in areas of a part that are unattainable with 2D systems. In a 3D vision inspection system, the target object image is no longer just a flat picture. It is now a three-dimensional point cloud of precise coordinates where the position of every pixel in space is known. It simultaneously provides X, Y, and Z plane data along with respective rotational information (around each of the axes) as well.

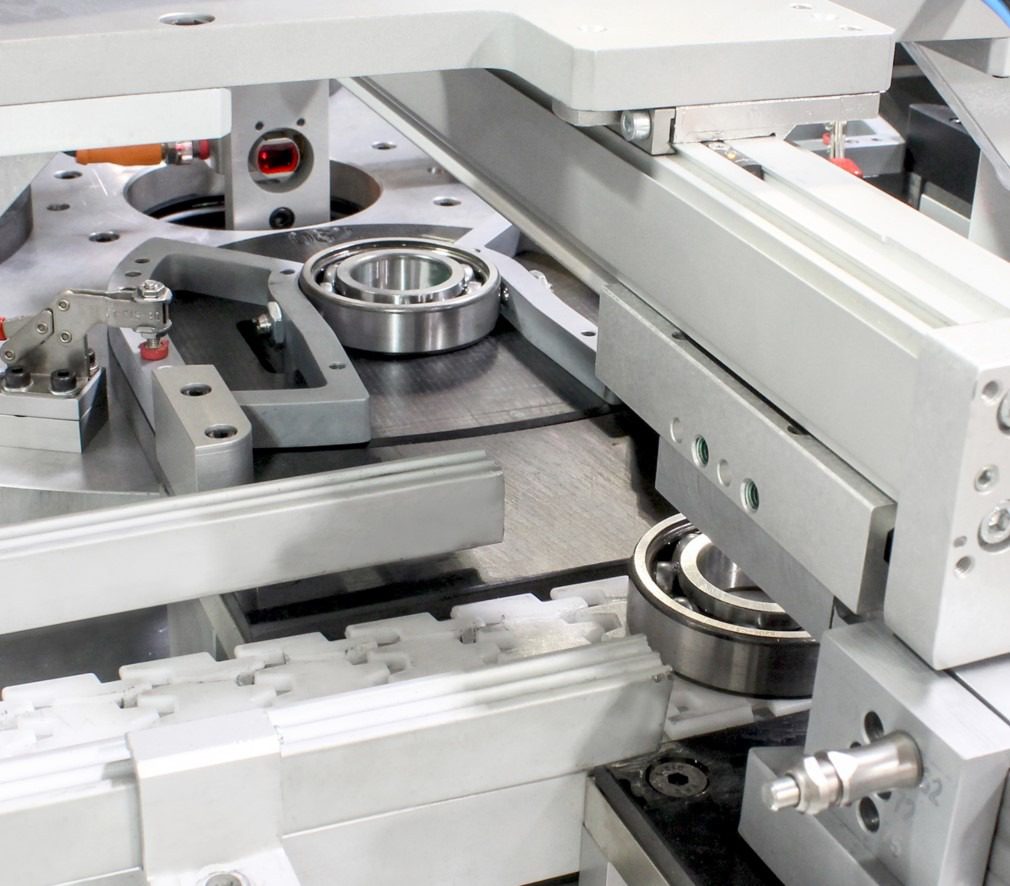

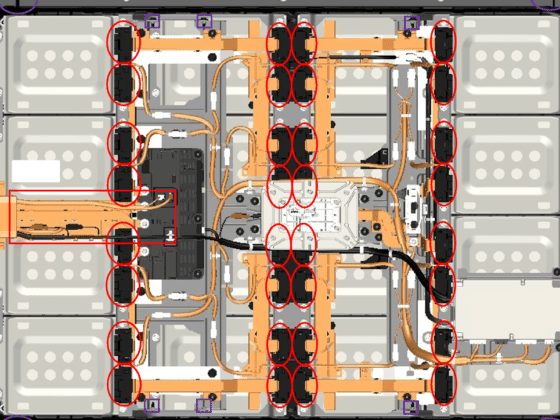

As a result of this much-extended capability, 3D vision inspection is being applied to a broad spectrum of tasks where 2D capability falls short, like some of the examples below.

- Thickness, height, and volume measurement

- Dimensioning and space management

- Measuring shapes, holes, angles, and curves

- Detection of surface or assembly defects

- Quality control and verification against 3D CAD Data

- Robot guidance and surface tracking (e.g., for welding, gluing, deburring, and more)

- Bin picking for placing, packing or assembly

- Object tracking and placement

Such complex, high accuracy, real-time challenges though are successfully resolved by applying the right mix of 3D machine vision technologies. It is providing efficient, cost-effective solutions where 2D machine vision cannot. With MESH Automation’s extensive experience in automation and machine vision, we can be the perfect partner for your next flexible automation project.

3D Machine Vision

3D machine vision systems are immune to the environmental factors adversely affecting 2D systems – the aspects of lighting, contrast, and distance to object are no longer an issue.

The quality and abilities of different 3D machine vision technologies can still make it a challenge to choose the right tool for the job.

It can be very difficult since the data provided is far more complex than that provided by a regular camera. You need to carefully consider a lot more requirements, including resolution, color, speed, and accuracy. MESH Automation is prepared with a fully equipped vision lab to help you find the right 2D and 3D machine vision inspection solution for your project.