MESH Palletizing and Handling of Flat Sheet Goods

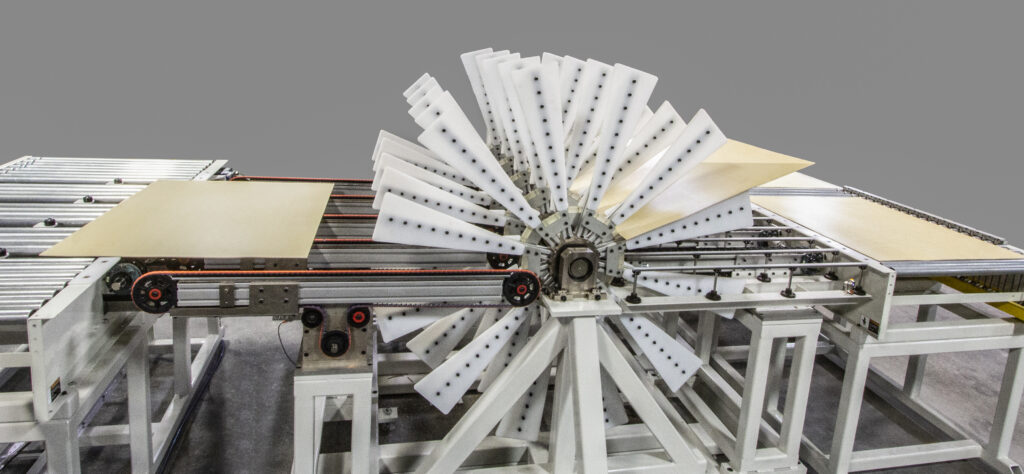

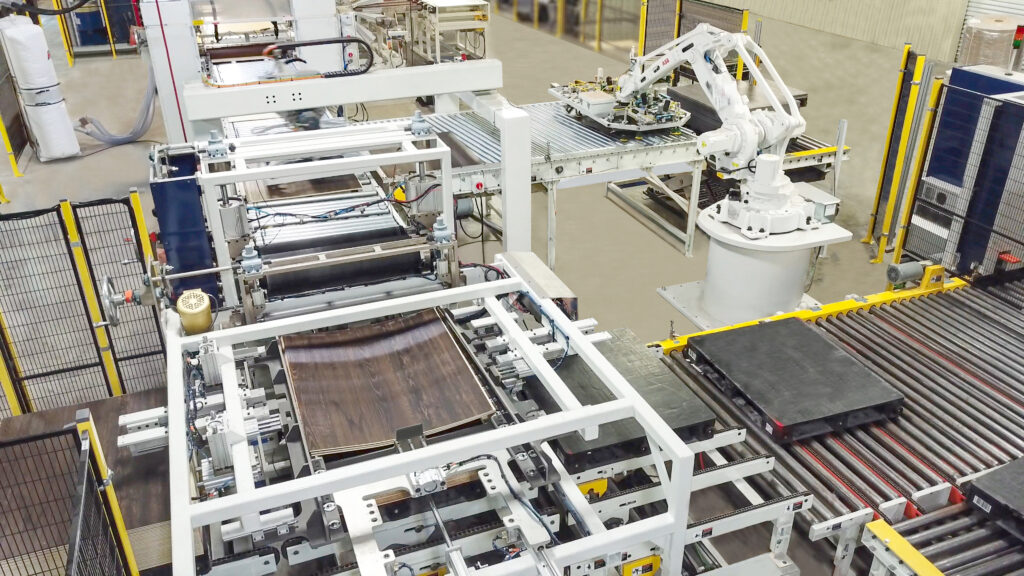

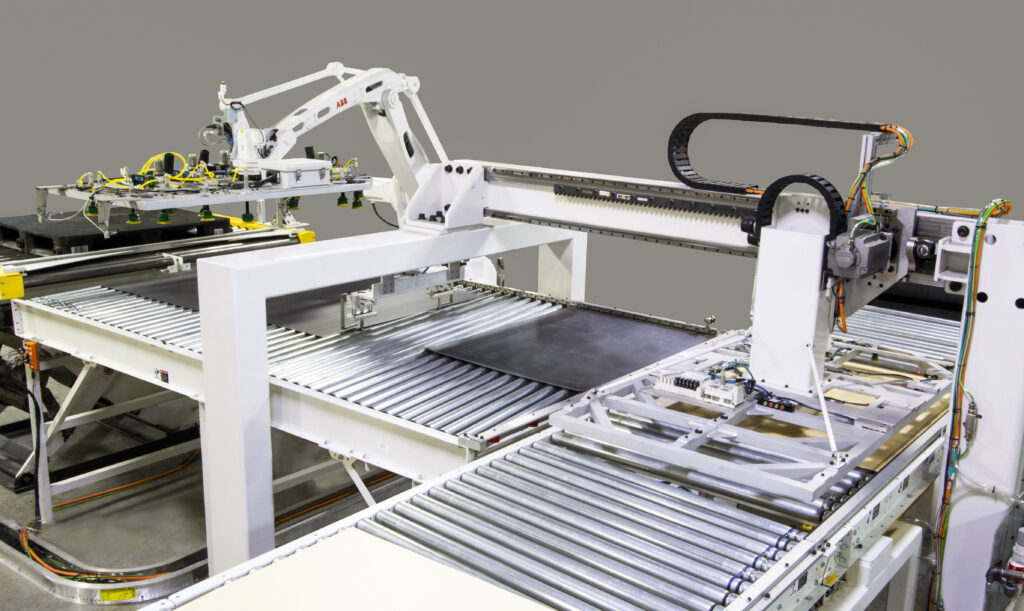

From metals to paper, automated flat sheet handling is needed in many industries. Flat sheets are typically described as a raw material but can also represent the end product. Automated handling of flat sheets is typically done via gantry or robot with the use of suction or magnetic tooling. Expertise in separating the sheets from each other, holding the sheet flat while transporting it, and keeping the sheet oriented in a preferred manner are very important in the design of a flat sheet handling system.

At MESH, we have the experience and library of tools that are proven to work in the automated handling of flat sheets into and out of machine centers and presses or the presentation of the sheet to a stud welding system, riveting head, or other similar system. Additionally, we have stacked finished products on a pallet using our palletizing experience.

Benefits of a MESH Flat Sheet Handling System

MESH has a wide experience range on flat sheets. Over the years, we have handled many metal products into and out of brake presses or stamping presses. We have stacked and destacked carpet tiles, MDF board, corrugate, PVC board, glass, and plywood. Our experience in this type of raw material, coupled with the post-handling process, is very extensive and spans many industries.

- Automation of flat sheet handling will likely increase production rates, improve labor utilization, improve job conditions (better ergonomics, less forklift interaction), reduce product waste, and improve product and package quality.

- Solutions for small batch size operations – Easy changeovers from the pushbutton changeover to quick change no tool technology. Simple systems for operators to understand what to do in a changeover.

- Flexible designs and specifications that cater to multiple product lines, future product modifications and changes, and with customized footprints to optimize floor space.

- Systems that can be integrated with planned or existing equipment.

- Product flexibility – Robots are the ultimate flexible automation tool when coupled with excellent and creative tool design.

- A comprehensive range of robot loading arms that suit specifications for speeds, unit loads, and layout requirements.

- Fewer risks of product damage because of the accuracy and control over the acceleration and deceleration of the product through the use of robotics.

Capabilities of a MESH designed flat sheet handling system

- Consistent and accurate handling of the product through good tool design and the use of robotics or precision motion control. 1mm accuracy is very feasible.

- Properly designed robots or gantries can run as fast as 15 picks per minute.

- With the use of a gantry MESH can design a system to handle products 4 meters long (or longer). Width can be up to 3 meters long.

- Dunnage – MESH can accommodate the most common dunnage requirements.

- Automated pallet and product delivery systems can be added.

- Vision inspection of the sheet can be added to enhance the value of the system.

- Safety – MESH designs our robotic and gantry systems to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

Flat Sheet Palletizing FAQ

When do you recommend a Gantry over a robot for flat sheet handling?

Gantries can handle large format sheets better than robots and can sometimes be more cost-effective when payloads and size start to max out the standard robot offerings. Additionally, if the pick location is far from the place location, a gantry may be a better option.

When is a robot the right automation tool for flat sheets?

Robots have the best value when six axes of motion are needed. This often comes into play in most machine tending operations or when an angular motion is needed to separate sheets during destacking.